- Lawn & Garden

- Agriculture

- Construction

- Landscaping & Grounds Care

- Golf & Sports Turf

- Forestry

- Engines & Drivetrains

- Government & Corporate Sales

- View All Equipment

- View Used Equipment

- Parts

- Manuals & Training

- Warranty & Protection Plans

- Expert Check

- John Deere Connected Support™

- StellarSupport™

- Recalls

- Safety

- Utility Tractors (23-195 Engine HP)

- Specialty Tractors (75-155 Engine HP)

- Row Crop Tractors (145-410 Engine HP)

- 4WD and Track Tractors (390-640 Engine HP)

- Utility Tractors Attachments & Accessories

- Tillage

- Combine Harvesters

- Cotton Harvesters

- Sugar Harvesters

- Hay & Forage

- Planting Equipment

- Seeding Equipment

- Gator™ Utility Vehicles

- Gator™ Attachments & Accessories

- Loaders for Tractors

- Scraper Systems

- Sprayers

- Precision Ag Technology

- Home & Workshop Products

- Used Agriculture Equipment

- INDUSTRIAL DIESEL ENGINES

- Final Tier 4/Stage V

- Interim Tier 4 / Stage III

- Tier 3/Stage III

- Tier 2 and Lesser Regulated

- MARINE ENGINES

- Commercial/Workboat

- Recreational/Pleasure Craft

- GENERATOR DRIVE ENGINES

- Standby/Stationary

- Prime/Portable

- DRIVETRAIN EQUIPMENT

- Pump Drives

- Transmissions

- Axles

- Planetary Gear Drives

- Vehicle Electrification

- TRACTORS & MOWERS

- Ride-On Mowers

- Utility Tractors (22.4-140 Engine HP)

- Specialty Tractors (75-155 Engine HP)

- Residential ZTrak™ Zero-Turn Mowers

- Commercial Mowers

- CONSTRUCTION

- Backhoes

- Compact Track Loaders

- Dozers

- Skid Steers

- Motor Graders

- Wheel Loaders

- UTILITY VEHICLES & ACCESSORIES

- Gator™ Utility Vehicles

- Gator™ Utility Vehicles Attachments & Accessories

- ATTACHMENTS & ACCESSORIES

- Attachments, Accessories & Implements

- Home & Workshop Products

- Front-End Loaders for Tractors

- Application Equipment

- Attachments, Accessories & Implements

- Backhoes

- Dozers

- Engines

- Forwarders

- Gator™ Utility Vehicles

- Hay & Forage

- Combine Harvesters

- Cotton Harvesters

- Sugar Harvesters

- Home & Workshop Products

- Motor Graders

- Mowers

- Planting Equipment

- Precision Ag Technology

- Scraper Systems

- Seeding Equipment

- Skidders

- Sprayers

- Swing Machines

- Tillage

- Tractors

- Home

- x166r ride on mower

Features

Powerful V-twin engine features full-pressure lubrication for dependability and long life

656-cc (40 cu in.) V-twin engine

656-cc (40 cu in.) V-twin engine

High-quality air filter

High-quality air filter

A large-displacement 656-cc (40 cu in.) V-twin engine has plenty of power and torque to handle tough mowing conditions:

- Powerful, 13 kW (17.4 hp) at 3150 rpm engine gives excellent performance.

- V-twin cylinder design has greater torque, lower vibration, and improved sound quality.

- Cast-iron cylinders give longer engine life.

- Overhead valves provide excellent power and fuel economy.

Engine speed control

Engine speed control

- Auto choke allows operators to start the engine without needing the choke unless air temperatures are near or below freezing.

- Electronic ignition gives fast starts.

- Full-pressure lubrication and oil filter ensure cleaner oil for longer engine life and extended time between oil changes.

- Full-pressure lubrication is also more effective when operating the tractor on an incline.

- John Deere Easy Change™ 30-second oil change system to make changing the engine oil easy, quick, and clean.

- Large, high-quality air filter element extends engine life and is easy to service.

John Deere Easy Change 30-second oil change system

John Deere Easy Change 30-second oil change system

John Deere Easy Change 30-second oil change system

The John Deere Easy Change 30-second oil change system makes changing the engine oil easy, quick, and clean. Changing the oil is as easy as removing the old oil-filled filter and twisting on a new oil-filled filter. Oil does not need to be drained from the engine. The removed filter contains the captured contaminants and a portion of the engine oil. Easy Change is standard equipment on the X166 and X166R.

Fuel tank has sight gauge to show fuel level from the operator’s seat

Fuel tank sight gauge

Fuel tank sight gauge

The fuel tank sight gauge allows the operator to tell how much fuel is in the tank without leaving the seat:

- Fuel level is easy to check.

- Convenient location – sight gauge can be seen from the operator’s seat.

- Fuel tank capacity is 8 L (2.1 gal.).

John Deere Easy Change™ 30-second oil change system

John Deere Easy Change 30-second oil change system

John Deere Easy Change 30-second oil change system

The John Deere Easy Change 30-second oil change system makes changing the engine oil easy, quick, and clean. Changing the oil is as easy as twisting on a new oil-filled filter. Oil does not need to be drained from the engine.

The John Deere Easy Change filter is an additional engine oil reservoir. Changing the filter removes the captured contaminants and replaces about 0.8 qt (0.76 L) of the engine oil.

The functionality does not stop with ease of use. The Easy Change oil system has several meaningful benefits over the traditional oil filter system of the 100 Series:

- A synthetic filter material is used for more predictable filtering and longer life.

- Filtering capacity is greater than with a standard oil filter.

- More filter surface area

- More oil flow capacity

- The system has 40 percent more oil volume.

- The oil and engine run cooler.

- The oil filter valve closes whenever the engine stops, so filtered particles are captured and cannot drain back into the engine.

- The risk of spilling during oil service is greatly reduced.

- Waste oil (and new oil production) is reduced by over 1,000,000 lb (453,592.4 kg) per tractor production year.

- This system is not a compromise to just make oil changes easier—these engines pass the same expectations and rigorous testing as always.

Partly due to these improvements, it is not necessary to remove and dispose of all the oil in the engine during service.

Everyone who uses the John Deere Easy Change system saves time and avoids the mess of a traditional oil change. In the past, many 100 Series Lawn Tractor owners rarely or never got around to changing their engine oil. With John Deere Easy Change, even owners who previously would not consider changing the oil themselves can easily do it. The Easy Change 30-second oil change system is a no-mess, no-fuss solution the competition cannot match.

Installation instructions are in the Operator’s Manual and in the John Deere Easy Change service part box.

Please recycle. Many local government recycling programs, authorized retailers, auto-service centers, and auto-parts stores will puncture and recycle used oil filters and oil.

Full-length welded steel frame for reliability

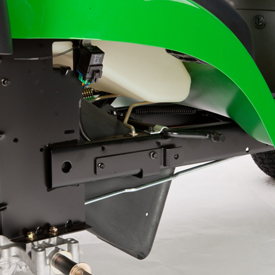

Heavy-duty rear hitch plate and frame

Heavy-duty rear hitch plate and frame

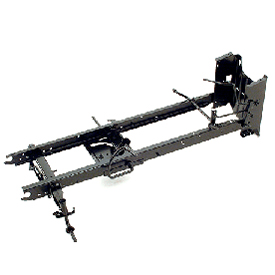

Solid one-piece welded frame

Solid one-piece welded frame

The solid one-piece frame is constructed of 12-gauge, 2.7-mm (0.105-in.) steel:

- Full-length robotically welded frame has high-strength steel rails for superior reliability and long life.

- One-piece fender deck is bolted to the frame.

Cast-iron front axle will not bend

X166R Tractor trimming around tree

X166R Tractor trimming around tree

Front axle and wheel spindle

Front axle and wheel spindle

The front axle is constructed of solid cast iron that will not bend:

- Automotive-like steering system with sector-and-pinion steering gears provide a very strong, low-effort, and tight-turning system.

- Grease fittings allow regular lubrication to help maintain easy steering and minimize wear.

- Large, 1.9-cm (0.75-in.) diameter front wheel spindles provide excellent durability.

Hood will not dent or rust and includes quality headlights for good visibility

Ultraviolet (UV)-resistant JD Loy hood

Ultraviolet (UV)-resistant JD Loy hood

Quality headlights for good visibility

Quality headlights for good visibility

The hood is made of injection-molded, UV-resistant JD Loy polymer:

- JD Loy material is tough and durable.

- Will not dent or rust

- Color is molded in for long-lasting good looks.

- UV-resistant JD Loy material resists fading.

- Openings on the side of the hood let in plenty of cooling air while keeping the sound level low.

- Two headlights provide good lighting for night-time operation.

Hydro/automatic drive gives an infinite choice of ground speeds

Hydro/automatic foot-control pedals

Hydro/automatic foot-control pedals

Hydro/automatic foot-control pedals

Hydro/automatic foot-control pedals

A Kanzaki® Tuff Torq® hydrostatic transmission gives an infinite choice of speeds and makes changing the direction of travel easy. Side-by-side foot pedals control the speed and direction of travel:

- Automotive-type accelerator control ensures easy operation.

- Operator can change direction without lifting foot off the platform.

Hydrostatic transmission

Hydrostatic transmission

A Kanzaki Tuff Torq hydrostatic transmission is used. It has the performance requirements to ensure excellent performance and reliability.

Kanzaki and Tuff Torq are trademarks of Kanzaki Kokyukoki Manufacturing Company.

Operator station designed for comfortable operation

Operator station is designed for comfort

Operator station is designed for comfort

Comfortable operator station (left view)

Comfortable operator station (left view)

Operator station is designed for operator comfort and easy operation:

- Controls are positioned where they are easy to reach and use to control the tractor.

- The steering wheel is positioned and angled to give the operator plenty of room and steering comfort.

- The seat is tilted back at the optimum angle to provide the most comfortable operator position.

Steering wheel and dash

Steering wheel and dash

Wide footrest with debris channels

Wide footrest with debris channels

Controls are easy to see and use:

- Deluxe steering wheel provides greater operator comfort and control. Steering wheel diameter is:

- 30.5 cm (12 in.) on the X146R

- 35.6 cm (14 in.) on the X166R

- Ignition switch is on the dash for starting ease.

Wide footrest areas with non-slip, anti-vibration rubber floor mats are provided for operator comfort and safety:

- Optimum operator comfort

- Debris removing channels help keep the footrest area clean and dry

High-back seat

High-back seat

Seat tilted up

Seat tilted up

A comfortable operator seat has a higher back for extra operator comfort. A comfortable seat is especially helpful when operating the tractor for extended periods of time. Seat-back height is 38.1 cm (15 in.).

Seat can be tilted forward for protection from the weather and to provide easy access to the fuel tank.

Seat springs give a smoother ride

Seat springs give a smoother ride

Easy-to-adjust seat

Easy-to-adjust seat

Seat springs absorb bumps to give a smoother ride.

Seat can be easily adjusted forward or backward while in the seat, with seat travel of 140 mm (5.5 in.) and 10 different positions.

Cup holder and storage with cover

Cup holder and storage with cover

Cup holder and storage with cover open

Cup holder and storage with cover open

A beverage holder and storage compartment are located on the right-side fender for operator convenience:

- The X166R storage compartment includes a cover to protect the contents from the elements.

- The cover can be ordered from Parts for the X166R and added to the X146R, if desired.

Controls are easy to find and convenient to use

Steering wheel and controls

Steering wheel and controls

Instruments and controls

The contoured dash is functional and attractive:

- The hour meter makes it easy to tell when oil changes and other maintenance should be performed.

- Controls are color-coded and labeled for easy identification by the operator.

- Controls are logically placed and easy to reach.

- The functional design of the controls provides good appearance and a comfortable feel.

Mower deck height adjustment

Mower deck height adjustment lever

Mower deck height adjustment lever

A spring-assisted, low-effort lift lever simplifies setting and adjusting the mower cut height:

- Increments of 0.64-cm (0.25-in.) allow the operator to fine-tune the cut height.

Transmission control

Side-by-side foot pedals

Side-by-side foot pedals

Two side-by-side pedals control the speed and direction of travel:

- Automotive-type accelerator control ensures easy operation.

- The operator can change direction without lifting foot off the platform.

- Large pedal surface gives superior operator comfort.

Electric power take-off (PTO) clutch is easy and convenient to use

PTO clutch switch

PTO clutch switch

The heavy-duty electric PTO clutch is operated with a convenient dash-mounted switch.

Parking brake control

Parking brake lever

Parking brake lever

Parking brake pedal

Parking brake pedal

The parking brake control is conveniently located for easy access. It holds the brake pedal securely in the locked position.

Serviceability is convenient with easy-open hood

One-piece hood is easy to open

One-piece hood is easy to open

Service interval decal located under hood

Service interval decal located under hood

The one-piece hood opens easily to permit checking and servicing the engine:

- Important service points are located within easy reach.

- A service-interval decal is provided inside the tractor hood for convenience when servicing the tractor.

Easy-to-service engine oil filter

Easy-to-service engine oil filter

Seat tilted up for easy access to fuel-fill opening

Seat tilted up for easy access to fuel-fill opening

The engine fuel and oil filters and the oil check/fill tube are exposed for serviceability when the hood is opened. The John Deere Easy Change™ 30-second oil change system makes changing the engine oil easy, quick, and clean. Changing the oil is as easy as twisting on a new oil-filled filter. Oil does not need to be drained from the engine.

The seat tilts up to protect it from the weather and for adding fuel.

Reverse implement option (RIO)

RIO switch

RIO switch

Mowing while backing up is strongly discouraged.

The operator who deems it necessary to keep the mower (or other implement) engaged while backing up should first bring the tractor to a stop and look behind the tractor to be sure there are no bystanders. Then actuate (push in) the RIO button. The RIO button must be held down in the reverse implement position as the shift lever is moved into reverse (reverse foot pedal is depressed on models with a hydrostatic transmission).

The operator may then release the button and the mower will continue to operate while backing up and also when resuming forward operation. This procedure must be repeated the next time the operator chooses to keep the mower engaged while backing up. If the mower power take-off (PTO) is engaged and the operator shifts into reverse or depresses the reverse pedal prior to pressing the RIO button, ignition to the engine will be shut off. The engine will stop unless the operator either pushes on the RIO switch or shifts out of reverse.

If the engine does stop, the operator must return the mower engagement (PTO) switch or lever to the off position, depress the brake pedal, and then turn the ignition switch to restart the engine.

107-cm (42-in.) Rear-Discharge Rear-Collect Mower Deck cuts clean

X166R with 107-cm (42-in.) Mower Deck

X166R with 107-cm (42-in.) Mower Deck

Heavy-duty V-belt drive, 92-cm (36-in.) Mower for X146R shown

Heavy-duty V-belt drive, 92-cm (36-in.) Mower for X146R shown

The innovative design of the 107-cm (42-in.) Edge™ Rear-Discharge Deck combines the best features for reliability and superior performance when mowing and collecting grass and leaves:

- The mower deck is stamped from 11-gauge, 3-mm (0.120-in.) steel to provide smooth contours for a quality appearance and excellent performance.

- With no side-discharge chute, the mower can trim on either side for mowing efficiency and convenience.

- A smaller storage area requirement is an additional benefit.

- A standard V-belt and non-timed blade design gives superior reliability and trouble-free operation.

- Offset mower blades permit blade overlap with the use of a standard V-belt drive.

- The blades cut cleanly without being able to contact each other.

- A heavy-duty V-belt and large spring-loaded idler pulley transfer power to the mower blades efficiently and reliably.

- Four mower wheels help level the mowing job and reduce the chance of scalping the lawn.

- Cut-height increments of 0.64 cm (0.25 in.) allow for operating the mower at the optimum cutting height.

- A quick-adjust deck-leveling system is provided to make keeping the deck properly adjusted easy.

Contoured deck and discharge blade, 92-cm (36-in.) Mower for X146R shown

Contoured deck and discharge blade, 92-cm (36-in.) Mower for X146R shown

The mower deck is contoured and free of obstructions to ensure optimum cutting and bagging performance:

- Grass clippings flow smoothly around the deck and up the chute into the hopper.

- Clipping buildup is minimized to ensure continued high-performance and easy cleanup.

- Special discharge blades (standard equipment) have a large wing to propel grass clippings up the chute and into the hopper.

- Mower fills and packs the 300-L (8.5-bu) hopper with a large volume of grass clippings and/or leaves.

Wash port

Wash port

Hose-end adapter example for use with wash port

Hose-end adapter example for use with wash port

Wash ports are provided on each side of the mower deck. They can be used to supply water to the underside of the deck so it can be easily cleaned after use:

- Wash ports are designed for a hose quick-connect fitting.

- Connect hose to the wash port on one side of the mower at a time and operate the mower to clean.

- Using the wash ports cleans bottom of deck and chute.

- Wash ports work best if used immediately after the mowing job is completed.

- Operating the mower deck while the water is running removes grass clippings.

- Use of the wash ports prevents buildup of material from affecting performance the next time the mower is used.

A hose-end adapter for the appropriate water hose to be used can be purchased locally for connection to the wash ports.

Optional rear deflector

Optional rear deflector

Optional rear deflector in operation

Optional rear deflector in operation

Optional rear deflector (BG20822) easily installs in place of hopper:

- No tools required for installation

- Deflects clippings in an even pattern behind the tractor

Optional mulch plug (typical mulch plug shown, not BG20560)

Optional mulch plug (typical mulch plug shown, not BG20560)

Optional mulch plug (BG20560) easily installs in place of hopper:

- When collecting grass clippings and leaves is not desired, a mulch plug and mulching blades are available. The rear hopper can be easily removed and the mulch plug installed.

- Plug closes off opening on bottom of deck so material cannot enter the chute.

- Special mulch blades are provided to optimize mulching performance.

- The mulching blades will also provide excellent performance when used with the rear-discharge deflector and good performance for collecting. If collecting in heavy or wet conditions, it may be necessary to reinstall the standard bagging blades for optimum performance.

Rear hopper has large 300-L (8.5-bu) capacity and is easy to empty

X146R Tractor mowing lawn

X146R Tractor mowing lawn

300-L (8.5-bu) hopper is raised to empty grass

300-L (8.5-bu) hopper is raised to empty grass

The large-capacity, rear-mounted hopper makes collecting grass and leaves easy. The rear design allows excellent maneuverability when mowing.

The 300-L (8.5-bu) capacity hopper holds a lot of material for longer mowing times between emptying. Emptying the hopper is easily accomplished from the operator’s seat.

The durable plastic bottom will last a long time, even when operating in rougher conditions.

Hopper-full sensing switch

Hopper-full sensing switch

Hopper-full indicator light on tractor dash

Hopper-full indicator light on tractor dash

When the hopper is full, a light on the dash will come on and an audible alarm will sound to alert the operator to disengage the power take-off (PTO).

- When there is enough material in the hopper to activate the sensing switch, it simultaneously turns on the dash-mounted hopper full indicator light and an audible alarm.

- This reduces the potential for plugging the system.

- The hopper must be full, with enough material to activate the hopper-full switch, to activate the hopper-full indicator and alarm.

Easy-to-empty 300-L (8.5-bu) hopper

Easy-to-empty 300-L (8.5-bu) hopper

Adjustable hopper latch

Adjustable hopper latch

The hopper is emptied by pulling up, then forward, on the hopper handle. Using the leverage of the long handle, pull forward hard enough to overcome the spring-loaded hopper latch and rotate the hopper upward.

The hopper latch is easily adjustable for operator preference and conditions:

- The spring can be located in any of three holes.

- More latching effort is required for hilly or rough operating conditions.

Front hopper support

Front hopper support

Standard-equipment hitch

Standard-equipment hitch

The hopper is easily removed from the tractor by using the rear handle to raise the back of the hopper 25 degrees, or about 13 cm (5 in.), and then using both handles to lift the hopper vertically out of the notches in the mounting brackets:

- No tools are required.

- There is nothing to disconnect.

When the hopper is removed from the tractor, it allows use of additional tractor features including:

- Optional rear deflector

- Optional mulch plug

- Rear implement hitch

- Tow-release lever

Interlock switches make the operator and others safer

Operator mowing with X146R Tractor

Operator mowing with X146R Tractor

Brake pedal and parking brake lock

Brake pedal and parking brake lock

Safety-interlock switches are designed to help protect the operator and others. The operator must be in the seat to start or operate the tractor. The brake pedal must be depressed or the parking brake set for the tractor engine to start.

Hopper-installed sensor switch

Hopper-installed sensor switch

When the hopper is removed, a safety interlock switch will prevent the mower deck from operating unless the rear deflector or mulch plug is installed, however the engine will run and the tractor will operate so the rear hitch can be used.