Back

- Lawn & Garden

- Agriculture

- Construction

- Landscaping & Grounds Care

- Golf & Sports Turf

- Forestry

- Engines & Drivetrains

- Government & Corporate Sales

- View All Equipment

- View Used Equipment

- Parts

- Manuals & Training

- Warranty & Protection Plans

- Expert Check

- John Deere Connected Support™

- StellarSupport™

- Recalls

- Safety

- Utility Tractors (23-195 Engine HP)

- Specialty Tractors (75-155 Engine HP)

- Row Crop Tractors (145-410 Engine HP)

- 4WD and Track Tractors (390-640 Engine HP)

- Utility Tractors Attachments & Accessories

- Tillage

- Combine Harvesters

- Cotton Harvesters

- Sugar Harvesters

- Hay & Forage

- Planting Equipment

- Seeding Equipment

- Gator™ Utility Vehicles

- Gator™ Attachments & Accessories

- Loaders for Tractors

- Scraper Systems

- Sprayers

- Precision Ag Technology

- Home & Workshop Products

- Used Agriculture Equipment

- INDUSTRIAL DIESEL ENGINES

- Final Tier 4/Stage V

- Interim Tier 4 / Stage III

- Tier 3/Stage III

- Tier 2 and Lesser Regulated

- MARINE ENGINES

- Commercial/Workboat

- Recreational/Pleasure Craft

- GENERATOR DRIVE ENGINES

- Standby/Stationary

- Prime/Portable

- DRIVETRAIN EQUIPMENT

- Pump Drives

- Transmissions

- Axles

- Planetary Gear Drives

- Vehicle Electrification

- TRACTORS & MOWERS

- Ride-On Mowers

- Utility Tractors (22.4-140 Engine HP)

- Specialty Tractors (75-155 Engine HP)

- Residential ZTrak™ Zero-Turn Mowers

- Commercial Mowers

- CONSTRUCTION

- Backhoes

- Compact Track Loaders

- Dozers

- Skid Steers

- Motor Graders

- Wheel Loaders

- UTILITY VEHICLES & ACCESSORIES

- Gator™ Utility Vehicles

- Gator™ Utility Vehicles Attachments & Accessories

- ATTACHMENTS & ACCESSORIES

- Attachments, Accessories & Implements

- Home & Workshop Products

- Front-End Loaders for Tractors

- Application Equipment

- Attachments, Accessories & Implements

- Backhoes

- Dozers

- Engines

- Forwarders

- Gator™ Utility Vehicles

- Hay & Forage

- Combine Harvesters

- Cotton Harvesters

- Sugar Harvesters

- Home & Workshop Products

- Motor Graders

- Mowers

- Planting Equipment

- Precision Ag Technology

- Scraper Systems

- Seeding Equipment

- Skidders

- Sprayers

- Swing Machines

- Tillage

- Tractors

- Home

- v451m round baler

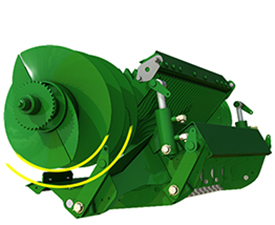

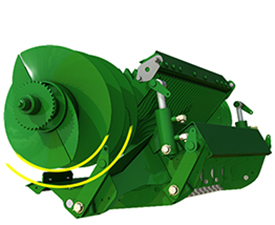

V451MVariable Chamber Baler

- High capacity, high performance 2.2 m wide feeding system

- High Capacity Rotor: 480 mm diameter converging auger

- Adjustable bale diameter in a 1.21 m bale chamber width for maximum bale weight

V451M

Features

Features

Expand All

Collapse All

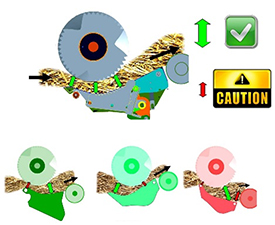

Left, pickup with cam track; right, cam-less pickup

Versatility has been one of the key criteria when designing the M-Series Balers. Due to a narrow weather window and increasing amounts of difficult crops such as heavy silage, growers do not want to risk losing any more time during the season.

Cam-track technology provides an efficient solution for such needs. The traditional stripper design provides reduced space between the pickup tines and rotor feeder, while the tine motion helps to avoid pinching. The cam-less technology requires long strippers, creating a dead zone between the tines and rotor. Additionally, fixed tines can easily pinch crops in sticky conditions, causing plugs that need to be manually removed.

Looking at potential component wear, cam-track pickup features an 18 percent lower turning speed than the previous generation of balers, while bearings have been implemented on both side of the tine bars. The cam levers are made of forged steel and cam bearing size increased by 36 percent. All of these points guarantee a very long component life.

Left, pickup with cam track; right, cam-less pickup

Versatility has been one of the key criteria when designing the M-Series Balers. Due to a narrow weather window and increasing amounts of difficult crops such as heavy silage, growers do not want to risk losing any more time during the season.

Cam-track technology provides an efficient solution for such needs. The traditional stripper design provides reduced space between the pickup tines and rotor feeder, while the tine motion helps to avoid pinching. The cam-less technology requires long strippers, creating a dead zone between the tines and rotor. Additionally, fixed tines can easily pinch crops in sticky conditions, causing plugs that need to be manually removed.

Looking at potential component wear, cam-track pickup features an 18 percent lower turning speed than the previous generation of balers, while bearings have been implemented on both side of the tine bars. The cam levers are made of forged steel and cam bearing size increased by 36 percent. All of these points guarantee a very long component life.

Standard – four tine bars – pickup

Standard – four tine bars – pickup

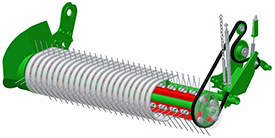

Full-length, L-shaped tine bars

M-Series Balers are available with a standard pickup. Two pickup widths are offered:

Full-length, L-shaped tine bars

M-Series Balers are available with a standard pickup. Two pickup widths are offered:

Premium – five tine bars – pickup

Premium – five tine bars – pickup

Tine bars made of tube and central spider reinforcement

For increased pickup capacity and robustness, M-Series Balers can be delivered with the premium pickup option. Compared to the standard pickup option, the premium pickup features:

Tine bars made of tube and central spider reinforcement

For increased pickup capacity and robustness, M-Series Balers can be delivered with the premium pickup option. Compared to the standard pickup option, the premium pickup features:

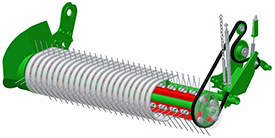

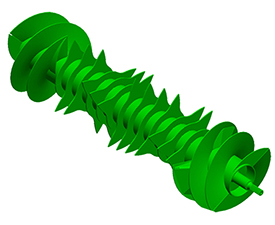

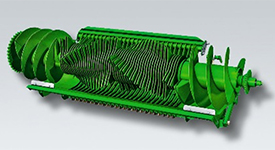

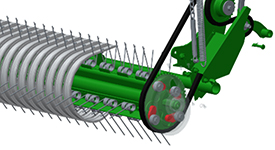

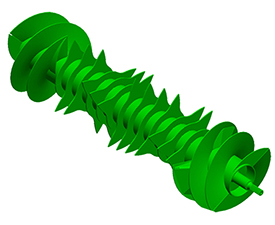

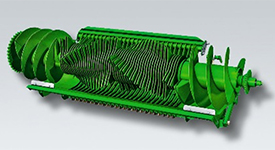

Rotor and converging augers are aligned on a single axle

Rotor and converging augers are aligned on a single axle

Left, HC rotor; right, classic rotor design

By using the HC Premium rotor – a device implemented on John Deere round balers since 2012 – the M-Series feeding system offers:

Left, HC rotor; right, classic rotor design

By using the HC Premium rotor – a device implemented on John Deere round balers since 2012 – the M-Series feeding system offers:

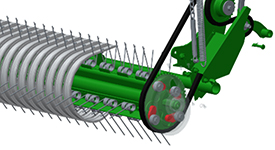

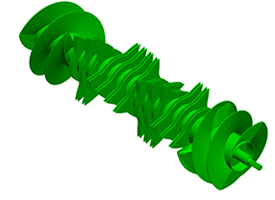

Premium rotor design with tines fully enclosing the tube

M-Series Round Balers can be delivered with the RotoFlow HC Premium non-cutting solution. All other John Deere round balers are equipped with a rotor feeder:

Premium rotor design with tines fully enclosing the tube

M-Series Round Balers can be delivered with the RotoFlow HC Premium non-cutting solution. All other John Deere round balers are equipped with a rotor feeder:

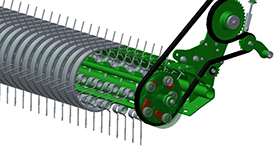

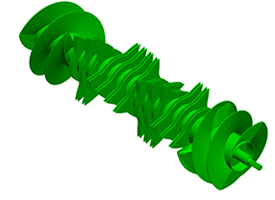

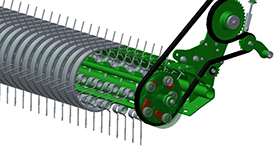

MaxiCut HC 13 Premium rotor

MaxiCut HC 13 Premium rotor

Knives individually protected

As an alternative to the RotoFlow HC Premium, M-Series Balers can be delivered with the MaxiCut HC 13 Premium rotor. As with the non-cutting system, the rotor features:

Knives individually protected

As an alternative to the RotoFlow HC Premium, M-Series Balers can be delivered with the MaxiCut HC 13 Premium rotor. As with the non-cutting system, the rotor features:

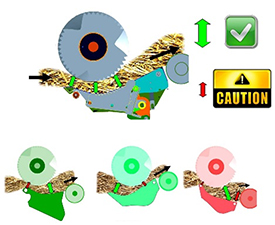

40-mm (1.6-in.) free space under the rotor

40-mm (1.6-in.) free space under the rotor

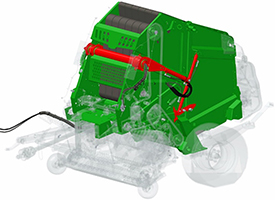

Parallel kinematic avoids bottleneck noticed with other concepts

M-Series Balers are delivered standard with a drop-floor unplugging system. In case of a clog, the drop floor is managed from the display simultaneously or independently from the knives. When lowering the floor, the parallel kinematic has 40-mm (1.6-in.) extra free space under the rotor and converging augers.

By providing a constant free space, the John Deere drop floor avoids bottlenecks existing on balers using a movable floor with front or rear hinge. No need to have a huge opening (that sometimes causes crop loss), only a few free centimeters (inches) are enough to remove the plug.

Parallel kinematic avoids bottleneck noticed with other concepts

M-Series Balers are delivered standard with a drop-floor unplugging system. In case of a clog, the drop floor is managed from the display simultaneously or independently from the knives. When lowering the floor, the parallel kinematic has 40-mm (1.6-in.) extra free space under the rotor and converging augers.

By providing a constant free space, the John Deere drop floor avoids bottlenecks existing on balers using a movable floor with front or rear hinge. No need to have a huge opening (that sometimes causes crop loss), only a few free centimeters (inches) are enough to remove the plug.

Full-width drop floor removes clogs under converging augers

The worst plugs generally happen when turning with the baler. In such situations, the crops are blocked under the converging augers and the clog must be manually removed. The unique John Deere drop floor features a full width, protecting the full pickup and rotor width. Even when plugged at the converging auger level, the clog can be easily removed by the operator from the cab.

Full-width drop floor removes clogs under converging augers

The worst plugs generally happen when turning with the baler. In such situations, the crops are blocked under the converging augers and the clog must be manually removed. The unique John Deere drop floor features a full width, protecting the full pickup and rotor width. Even when plugged at the converging auger level, the clog can be easily removed by the operator from the cab.

1.65-m (5.4-ft) x 1.21-m (3.97-ft) bales are heavy weight

As with the other G-, M-, and R-Series Balers, the V451M Baler features a 1.21-m (3.97-ft) bale chamber width. Compared to previous generation balers with similar bale diameters, bales are up to 3.6 percent larger than before. Considering the slightly larger bales have a similar density, that is a huge advantage.

The bale diameter on the V451M Baler can be adjusted from 1.0 m (3.3 ft) to 1.65 m (5.4 ft) using the monitor. The maximum diameter of 1.65 m (5.4 ft) is an added 10 cm (3.9 in.) compared to the previous generation. This allows the grower to produce bales up to 17 percent larger than previous 854 and also facilitates production of similar 1.60-m (5.25-ft) hay and straw bales.

Bale diameter progress can be followed from the monitor no matter the display choice.

1.65-m (5.4-ft) x 1.21-m (3.97-ft) bales are heavy weight

As with the other G-, M-, and R-Series Balers, the V451M Baler features a 1.21-m (3.97-ft) bale chamber width. Compared to previous generation balers with similar bale diameters, bales are up to 3.6 percent larger than before. Considering the slightly larger bales have a similar density, that is a huge advantage.

The bale diameter on the V451M Baler can be adjusted from 1.0 m (3.3 ft) to 1.65 m (5.4 ft) using the monitor. The maximum diameter of 1.65 m (5.4 ft) is an added 10 cm (3.9 in.) compared to the previous generation. This allows the grower to produce bales up to 17 percent larger than previous 854 and also facilitates production of similar 1.60-m (5.25-ft) hay and straw bales.

Bale diameter progress can be followed from the monitor no matter the display choice.

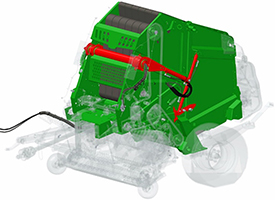

Dedicated cylinders for tailgate and density system plus mechanical tailgate lock

The V451M bale chamber provides high-density bales regardless of the bale diameter or crop type. A dedicated pair of cylinders apply strength to the density arm while mechanical hooks firmly lock the tailgate in the closed position. Another pair of cylinders manages the tailgate opening/closing and avoids potential interferences between the two functions and tension loss to the belts.

When the baler is equipped with the BaleTrak™ Plus display, the following pressure parameters can be adjusted/controlled from the display:

Dedicated cylinders for tailgate and density system plus mechanical tailgate lock

The V451M bale chamber provides high-density bales regardless of the bale diameter or crop type. A dedicated pair of cylinders apply strength to the density arm while mechanical hooks firmly lock the tailgate in the closed position. Another pair of cylinders manages the tailgate opening/closing and avoids potential interferences between the two functions and tension loss to the belts.

When the baler is equipped with the BaleTrak™ Plus display, the following pressure parameters can be adjusted/controlled from the display:

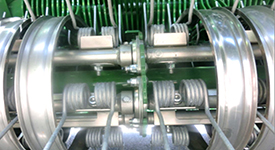

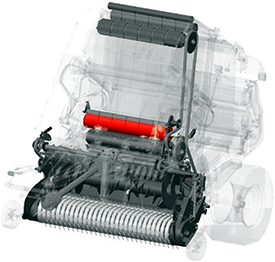

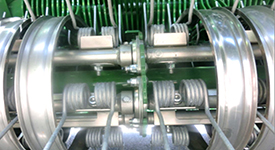

Three bale chamber rolls facilitate bale rotation

Three bale chamber rolls facilitate bale rotation

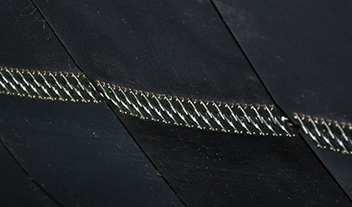

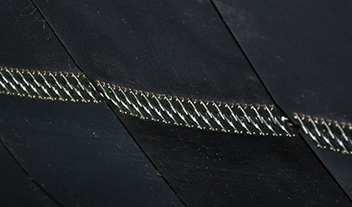

Laced belts can be changed or repaired quickly and for limited cost

The V451M bale chamber features a starter roll and two front rolls, all driven, for quick crop rotation whether harvesting short silage or brittle crops.

Easy bale starting is provided by the three rolls, avoiding the aggressive belt pattern that often causes crop accumulation. The six belts – derived from traditional diamond John Deere belts – keep the three plies but adopt a smooth pattern. This pattern (similar to R-Series Balers) is almost not sensitive to wear.

The belts are all joined thanks to proven and durable MATO® type lacers. In case of trouble, belts can be easily removed and repaired, something not possible with an endless belt design.

Due to initial empty bale chamber geometry, V451M Balers feature a star-shaped core comparable to the one offered by fixed-chamber balers. This starred shape guarantees easy bale unrolling, regardless of density settings.

MATO is a trademark of MATO GmbH & Co.

Laced belts can be changed or repaired quickly and for limited cost

The V451M bale chamber features a starter roll and two front rolls, all driven, for quick crop rotation whether harvesting short silage or brittle crops.

Easy bale starting is provided by the three rolls, avoiding the aggressive belt pattern that often causes crop accumulation. The six belts – derived from traditional diamond John Deere belts – keep the three plies but adopt a smooth pattern. This pattern (similar to R-Series Balers) is almost not sensitive to wear.

The belts are all joined thanks to proven and durable MATO® type lacers. In case of trouble, belts can be easily removed and repaired, something not possible with an endless belt design.

Due to initial empty bale chamber geometry, V451M Balers feature a star-shaped core comparable to the one offered by fixed-chamber balers. This starred shape guarantees easy bale unrolling, regardless of density settings.

MATO is a trademark of MATO GmbH & Co.

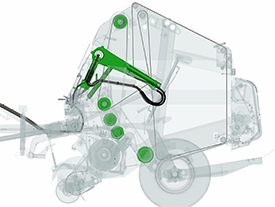

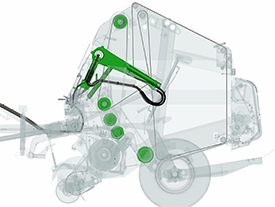

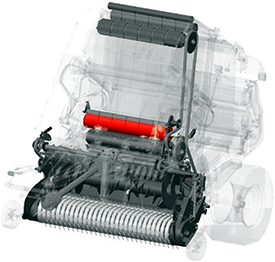

Second belt-driving roll

The V451M can be equipped with a second belt-driving roll, providing extra grip when baling wet crops such as heavy silage. In such conditions, this second roll prevents belt slipping and allows the belts to turn in the worst conditions.

The second belt-driving roll is made of metal and is driven through normal chain tracking. No extra chains or complicated clutch systems are required to drive the roll. Thanks to a freewheel, the second belt-driving roll is only activated in case of belt slippage.

The second belt-driving roll is an option with the RotoFlow HC Premium feeding system, while it is installed standard with the MaxiCut™ HC 13 Premium rotor. Two cleaning rollers are also included in the option and keep the crops from sticking on the belts and causing belt slippage.

A second belt-driving roll is also offered as an attachment through the traditional field kit channel.

Second belt-driving roll

The V451M can be equipped with a second belt-driving roll, providing extra grip when baling wet crops such as heavy silage. In such conditions, this second roll prevents belt slipping and allows the belts to turn in the worst conditions.

The second belt-driving roll is made of metal and is driven through normal chain tracking. No extra chains or complicated clutch systems are required to drive the roll. Thanks to a freewheel, the second belt-driving roll is only activated in case of belt slippage.

The second belt-driving roll is an option with the RotoFlow HC Premium feeding system, while it is installed standard with the MaxiCut™ HC 13 Premium rotor. Two cleaning rollers are also included in the option and keep the crops from sticking on the belts and causing belt slippage.

A second belt-driving roll is also offered as an attachment through the traditional field kit channel.

Pickup choice fits the most demanding growers

Cam-track design offers the best versatility

Left, pickup with cam track; right, cam-less pickup

Left, pickup with cam track; right, cam-less pickupStandard pickup fits most regular baling conditions

Standard – four tine bars – pickup

Standard – four tine bars – pickup Full-length, L-shaped tine bars

Full-length, L-shaped tine bars- 2.0-m (6.6-ft) standard pickup featuring a 1.66-m (5.45-ft) tine-to-tine distance. This pickup is compatible with the MaxiCut™ HC 13 Premium rotor only, not with the RotoFlow HC Premium.

- 2.2-m (7.2-ft) standard pickup featuring a 1.92-m (6.3-ft) tine-to-tine distance.

- Four tine bars

- Full-width, L-shaped galvanized tine bars

- 5.0-mm (0.2-in.) diameter galvanized tines

Premium pickup pushes harvesting capacity a step forward

Premium – five tine bars – pickup

Premium – five tine bars – pickup Tine bars made of tube and central spider reinforcement

Tine bars made of tube and central spider reinforcement- Five tine bars. The fifth bar allows the tines to rake two more times per second versus standard the four-tine pickup.

- O-shaped tubular tine bars with central spider reinforcement. Tine bars are assembled with ball bearings on the central spider (no more steel-on-steel contact compared to previous-generation balers). The central spider highly limits tine bars bending in the very heavy crops.

- 6.0-mm (0.23-in.) diameter galvanized tines provide doubled tine strength (versus 5.0 mm [0.2 in.]).

- Stainless-steel strippers (versus galvanized ones on the standard pickup). Stainless steel gives highly durable rust protection, perfect gliding capacity no matter the material, and is much more resistant to acid damage caused by usage of additives (e.g. propionic acid).

High-Capacity (HC) Premium rotors grab the toughest swaths

The M-Series benefits from the proven HC rotor concept featuring an in-line design

Rotor and converging augers are aligned on a single axle

Rotor and converging augers are aligned on a single axle Left, HC rotor; right, classic rotor design

Left, HC rotor; right, classic rotor design - Limited distance from the pickup to the rotor tines to reduce plugging, especially in brittle straw or short silage

- Reduced number of bearings and distributed loads along the rotor to increase reliability

- Large 48-cm (18.9-in.) diameter converging augers to facilitate crop transfer

RotoFlow HC Premium is the perfect solution for non-cutting uses

Premium rotor design with tines fully enclosing the tube

Premium rotor design with tines fully enclosing the tube- Close to 50-cm (19.7-in.) diameter rotor for high inertia and feeding capacity

- Hardox® wear plate material (similar to the R-Series) to provide long lifespan and high resistance to foreign objects

- Three tines per turn (instead of two on the G-Series RotoFlow HC).

- Tines that fully enclose the tube (instead of spikes on the G-Series RotoFlow HC), giving higher tine resistance and longer lifetime.

MaxiCut™ HC 13 Premium offers high versatility, huge capacity, and perfect cutting quality regardless of crop type

MaxiCut HC 13 Premium rotor

MaxiCut HC 13 Premium rotor Knives individually protected

Knives individually protected- Close to 50-cm (19.7-in.) diameter rotor for high inertia and feeding capacity

- Hardox wear plate material (similar to the R-Series) to provide long lifespan and high resistance to foreign objects

- Three tines per turn (instead of two on the G-Series RotoFlow HC)

- Tines that fully enclose the tube (instead of spikes on the G-Series RotoFlow HC), giving higher tine resistance and longer lifetime

- 0/13 knife engagement from the display. No need to leave the cab to manage knives.

- 80-mm (3.1-in.) knife spacing when all knives are engaged, a common cutting length for medium to large livestock farms.

- Heavy-duty knives thanks to double hardening and tempering treatment. Crops are perfectly cut, requiring less fuel consumption and sharpening operations.

- Individually spring-loaded knives to avoid component damages when grabbing foreign objects. Compared to a shear bolt or full-set hydraulic system, this technology limits efforts on the knives and provides a real non-stop safety.

Exclusive drop-floor concept removes the worst plugs

40-mm (1.6-in.) free space under the rotor

40-mm (1.6-in.) free space under the rotor Parallel kinematic avoids bottleneck noticed with other concepts

Parallel kinematic avoids bottleneck noticed with other concepts Full-width drop floor removes clogs under converging augers

Full-width drop floor removes clogs under converging augersBale chamber delivers heavy, dense, and perfectly shaped bales

Bales up to 1.65 m (5.4 ft) diameter maximizes weight

1.65-m (5.4-ft) x 1.21-m (3.97-ft) bales are heavy weight

1.65-m (5.4-ft) x 1.21-m (3.97-ft) bales are heavy weightHigh density provided regardless of bale diameter

Dedicated cylinders for tailgate and density system plus mechanical tailgate lock

Dedicated cylinders for tailgate and density system plus mechanical tailgate lock- Softcore activation/deactivation

- Softcore diameter (from 1.0 m [3.3 ft])

Bale chamber design optimizes machine versatility

Three bale chamber rolls facilitate bale rotation

Three bale chamber rolls facilitate bale rotation Laced belts can be changed or repaired quickly and for limited cost

Laced belts can be changed or repaired quickly and for limited costSecond belt-driving roll pushes silage baling capacity a step forward

Second belt-driving roll

Second belt-driving rollMonitor choice optimizes functions to operator’s needs

The V451M and V461M can be delivered with the proven and simple BaleTrak™ Plus monitor.

BaleTrak Plus monitor

For operators looking for a simple, efficient, and proven monitor, M-Series Balers can be delivered with the BaleTrak Plus monitor.

This display offers:

BaleTrak Plus monitor

For operators looking for a simple, efficient, and proven monitor, M-Series Balers can be delivered with the BaleTrak Plus monitor.

This display offers:

BaleTrak Plus monitor fits regular use

BaleTrak Plus monitor

BaleTrak Plus monitor- Settings

- Knife engagement/disengagement

- Drop-floor lowering/raising

- Bale diameter adjustment

- Softcore activation/deactivation

- Softcore diameter adjustment

- Net/twine choice

- Manual tying/wrapping starting

- Manual net/twine cylinder control

- Net layers adjustment

- Net tying delay adjustment

- Twine turns on each side (independent) adjustment

- Twine spacing adjustment

- Twine space to the edges adjustment

- B-Wrap® system mode activation

- Information

- Bale shape indicators

- Near full alarm

- Oversize alarm

- Stop indicator

- Net/twine choice

- Net alarm

- Tailgate status

- Softcore status

- Bale counter (five daily plus one total)

- Battery alarm

Offers and Discounts

Related Products

Product Information & Support

You May Also Be Interested In

Product features are based on published information at the time of publication. Product features are subject to change without notice. Contact your local John Deere dealer for more information.