Back

- Lawn & Garden

- Agriculture

- Construction

- Landscaping & Grounds Care

- Golf & Sports Turf

- Forestry

- Engines & Drivetrains

- Government & Corporate Sales

- View All Equipment

- View Used Equipment

- Parts

- Manuals & Training

- Warranty & Protection Plans

- Expert Check

- John Deere Connected Support™

- StellarSupport™

- Recalls

- Safety

- Utility Tractors (23-195 Engine HP)

- Specialty Tractors (75-155 Engine HP)

- Row Crop Tractors (145-410 Engine HP)

- 4WD and Track Tractors (390-640 Engine HP)

- Utility Tractors Attachments & Accessories

- Tillage

- Combine Harvesters

- Cotton Harvesters

- Sugar Harvesters

- Hay & Forage

- Planting Equipment

- Seeding Equipment

- Gator™ Utility Vehicles

- Gator™ Attachments & Accessories

- Loaders for Tractors

- Scraper Systems

- Sprayers

- Precision Ag Technology

- Home & Workshop Products

- Used Agriculture Equipment

- INDUSTRIAL DIESEL ENGINES

- Final Tier 4/Stage V

- Interim Tier 4 / Stage III

- Tier 3/Stage III

- Tier 2 and Lesser Regulated

- MARINE ENGINES

- Commercial/Workboat

- Recreational/Pleasure Craft

- GENERATOR DRIVE ENGINES

- Standby/Stationary

- Prime/Portable

- DRIVETRAIN EQUIPMENT

- Pump Drives

- Transmissions

- Axles

- Planetary Gear Drives

- Vehicle Electrification

- TRACTORS & MOWERS

- Ride-On Mowers

- Utility Tractors (22.4-140 Engine HP)

- Specialty Tractors (75-155 Engine HP)

- Residential ZTrak™ Zero-Turn Mowers

- Commercial Mowers

- CONSTRUCTION

- Backhoes

- Compact Track Loaders

- Dozers

- Skid Steers

- Motor Graders

- Wheel Loaders

- UTILITY VEHICLES & ACCESSORIES

- Gator™ Utility Vehicles

- Gator™ Utility Vehicles Attachments & Accessories

- ATTACHMENTS & ACCESSORIES

- Attachments, Accessories & Implements

- Home & Workshop Products

- Front-End Loaders for Tractors

- Application Equipment

- Attachments, Accessories & Implements

- Backhoes

- Dozers

- Engines

- Forwarders

- Gator™ Utility Vehicles

- Hay & Forage

- Combine Harvesters

- Cotton Harvesters

- Sugar Harvesters

- Home & Workshop Products

- Motor Graders

- Mowers

- Planting Equipment

- Precision Ag Technology

- Scraper Systems

- Seeding Equipment

- Skidders

- Sprayers

- Swing Machines

- Tillage

- Tractors

- Home

- f441m round baler euro spec

F441MRound Baler

- Low to frequent, versatile use

- High specification build quality

- Multicrop performer

- Bale chamber choice

F441M

Features

Features

Expand All

Collapse All

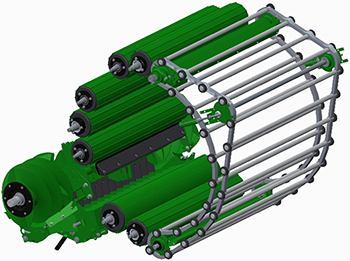

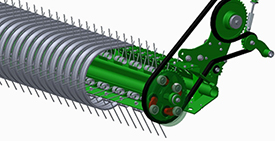

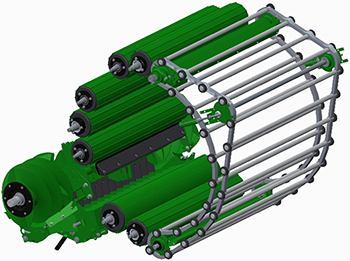

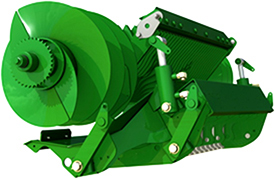

F441M with MultiCrop tailgate combines advantages of rolls and conveyor technologies

This baler provides versatility to small and medium farms because of its ability to harvest wet and dry crops.

Due to the slats conveyor integrated in to the tailgate, the MultiCrop gate efficiently grabs dry crops. Even in hot brittle barley straw, bales are constantly rotating from the beginning of the process to the tying process.

Combined with a front chamber featuring powered 12 ribbed rolls, the F441M MultiCrop provides high fixed chamber baler versatility.

F441M with MultiCrop tailgate combines advantages of rolls and conveyor technologies

This baler provides versatility to small and medium farms because of its ability to harvest wet and dry crops.

Due to the slats conveyor integrated in to the tailgate, the MultiCrop gate efficiently grabs dry crops. Even in hot brittle barley straw, bales are constantly rotating from the beginning of the process to the tying process.

Combined with a front chamber featuring powered 12 ribbed rolls, the F441M MultiCrop provides high fixed chamber baler versatility.

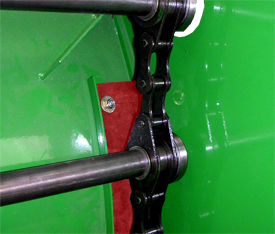

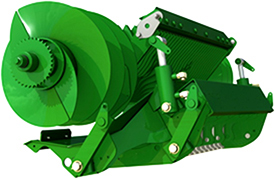

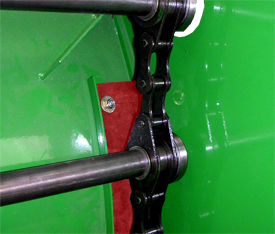

Noise absorber makes conveyer silent

Thanks to clever design, the MultiCrop gate eliminates:

Noise absorber makes conveyer silent

Thanks to clever design, the MultiCrop gate eliminates:

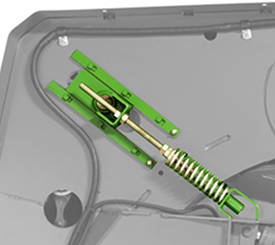

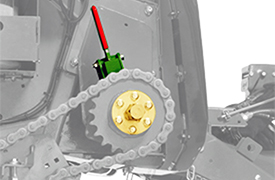

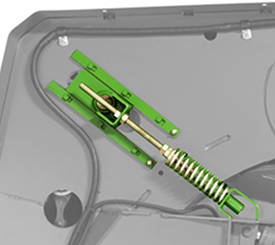

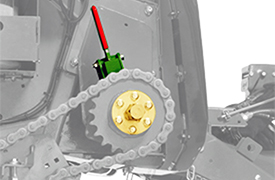

Tensioner optimizes chain lifespan

Tensioner optimizes chain lifespan

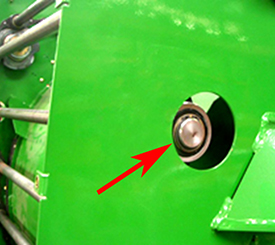

Slats can be easily changed

Increasing the number of chains is often linked to high maintenance and reduced lifetime. The MultiCrop gate has two idlers that optimize chain tension to enhance chain lifespan.

An aperture on each tailgate side allows the operator to check and replace slat bearings. Due to heavy-duty slats (35-mm [1.4-in.] diameter), the bending of parts is rare and the apertures can be replaced without dismounting the conveyor.

Slats can be easily changed

Increasing the number of chains is often linked to high maintenance and reduced lifetime. The MultiCrop gate has two idlers that optimize chain tension to enhance chain lifespan.

An aperture on each tailgate side allows the operator to check and replace slat bearings. Due to heavy-duty slats (35-mm [1.4-in.] diameter), the bending of parts is rare and the apertures can be replaced without dismounting the conveyor.

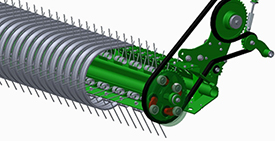

Left – pickup with cam track / right – cam-less pickup

The F441M Baler provides operators with a single baler to harvest all kinds of crops, from gliding straw to short, sticky silage. Cam-track technology provides an efficient solution for such needs. The traditional stripper design provides reduced space between the pickup tines and rotor feeder, while the tine motion helps to avoids pinching.

The cam-less technology requires long strippers, creating a dead-zone between the tines and rotor. Additionally, fixed tines can easily pinch crops in sticky conditions, causing plugs that need to be manually removed.

Left – pickup with cam track / right – cam-less pickup

The F441M Baler provides operators with a single baler to harvest all kinds of crops, from gliding straw to short, sticky silage. Cam-track technology provides an efficient solution for such needs. The traditional stripper design provides reduced space between the pickup tines and rotor feeder, while the tine motion helps to avoids pinching.

The cam-less technology requires long strippers, creating a dead-zone between the tines and rotor. Additionally, fixed tines can easily pinch crops in sticky conditions, causing plugs that need to be manually removed.

Four tine bars match good picking capacity

The F441M Balers feature a 2.0- or 2.2-m (6.5- or 7.2-ft) pickup and galvanized strippers for an extended lifespan. The four-tine bars mounted on sealed ball bearings and equipped with 5-mm (0.2-in.) diameter tines meet the picking capacity expected by small and medium size farms.

Four tine bars match good picking capacity

The F441M Balers feature a 2.0- or 2.2-m (6.5- or 7.2-ft) pickup and galvanized strippers for an extended lifespan. The four-tine bars mounted on sealed ball bearings and equipped with 5-mm (0.2-in.) diameter tines meet the picking capacity expected by small and medium size farms.

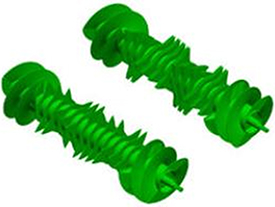

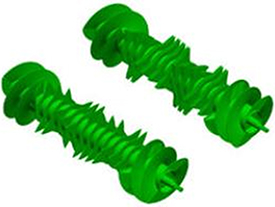

Left – HC rotor / right – classic rotor design

The F441M features an HC rotor design already used on the previous model F440M. This simple design offers several key advantages:

Left – HC rotor / right – classic rotor design

The F441M features an HC rotor design already used on the previous model F440M. This simple design offers several key advantages:

RotoFlow HC and MaxiCut™ HC 13 rotors are available on the F441M

The F441M is available without a precutter (RotoFlow HC Premium feeder). MaxiCut HC Premium 13 knives is proposed as alternative solution for operators searching for a regular precutter with 80-mm (3-in.) space between knives. In order to provide quality cutting, knives are individually secured by springs to protect against foreign objects and are double heat treated for longer durability. The full set of knives is controlled by a hydraulic valve conveniently located on the front of the baler.

RotoFlow HC and MaxiCut™ HC 13 rotors are available on the F441M

The F441M is available without a precutter (RotoFlow HC Premium feeder). MaxiCut HC Premium 13 knives is proposed as alternative solution for operators searching for a regular precutter with 80-mm (3-in.) space between knives. In order to provide quality cutting, knives are individually secured by springs to protect against foreign objects and are double heat treated for longer durability. The full set of knives is controlled by a hydraulic valve conveniently located on the front of the baler.

Exclusive drop floor removes the worst plugs

Exclusive drop floor removes the worst plugs

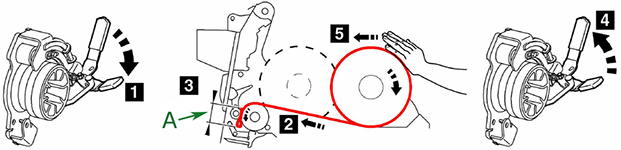

Rotor wrench offered as an economical solution for RotoFlow HC Premium

As with the high-spec F441R Baler, the drop floor makes removing plugs easy, even those under converging augers. This exclusive design covers the rotor width, so wherever a plug occurs, the unplugging device decompresses the crops and feeds the plug into the baler.

Parallel kinematics provides a consistent 40-mm (1.6-in.) space on the entire drop floor, eliminating narrow pinch points like front- hinged drop floors have.

The drop floor is easily controlled by a hydraulic valve located on the control panel. The drop floor is standard for the F441M, when equipped with the MaxiCut HC Premium 13.

For a RotoFlow HC Premium equipped baler, the drop floor system is proposed as an option. Even without this system, the F441M can be unplugged without the operator reaching their hands into the pickup. If this happens, the operator needs to declutch the rotor, put the wrench on the rotor, and reverse to remove the compressed crops.

Hardox is a trademark of SSAB Technology AB.

Rotor wrench offered as an economical solution for RotoFlow HC Premium

As with the high-spec F441R Baler, the drop floor makes removing plugs easy, even those under converging augers. This exclusive design covers the rotor width, so wherever a plug occurs, the unplugging device decompresses the crops and feeds the plug into the baler.

Parallel kinematics provides a consistent 40-mm (1.6-in.) space on the entire drop floor, eliminating narrow pinch points like front- hinged drop floors have.

The drop floor is easily controlled by a hydraulic valve located on the control panel. The drop floor is standard for the F441M, when equipped with the MaxiCut HC Premium 13.

For a RotoFlow HC Premium equipped baler, the drop floor system is proposed as an option. Even without this system, the F441M can be unplugged without the operator reaching their hands into the pickup. If this happens, the operator needs to declutch the rotor, put the wrench on the rotor, and reverse to remove the compressed crops.

Hardox is a trademark of SSAB Technology AB.

Loading ramp assists roll handling

Even with long net rolls, a roll is changed at least twice a day. Operators lifting 40-kg (88-lb) rolls over 2.0-m (6.6-ft) can cause serious injury. A convenient loading ramp allows the operator to easily push the heavy net rolls to the wrapping system and to the roll storage device.

When equipped with net wrapping, the F441M Baler has one roll installed in the device and one roll, up to 300-mm (11.81-in.) diameter, in the storage.

An additional box is available as an option. The additional box is delivered as standard with the net and twine option.

The additional box can be retrofitted to all existing F441M Balers. It is only required to remove a lateral plate from the baler and install the field bundle.

Loading ramp assists roll handling

Even with long net rolls, a roll is changed at least twice a day. Operators lifting 40-kg (88-lb) rolls over 2.0-m (6.6-ft) can cause serious injury. A convenient loading ramp allows the operator to easily push the heavy net rolls to the wrapping system and to the roll storage device.

When equipped with net wrapping, the F441M Baler has one roll installed in the device and one roll, up to 300-mm (11.81-in.) diameter, in the storage.

An additional box is available as an option. The additional box is delivered as standard with the net and twine option.

The additional box can be retrofitted to all existing F441M Balers. It is only required to remove a lateral plate from the baler and install the field bundle.

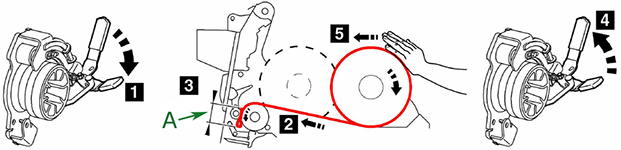

Very simple net tracking

Once placed in the wrapping device, the net is easy to install. Declutch the net system and push the net between the feeding rolls. Re-engage the system and close the shielding. The process is completed in less than a minute.

Very simple net tracking

Once placed in the wrapping device, the net is easy to install. Declutch the net system and push the net between the feeding rolls. Re-engage the system and close the shielding. The process is completed in less than a minute.

Convenient ladder access from both sides

A convenient loading platform accessible from both sides of the machines allows the operator to easily put in place the roll and setup the bale tying system.

Depending on the chosen monitor, any wrapping issues can be communicated by the display.

Convenient ladder access from both sides

A convenient loading platform accessible from both sides of the machines allows the operator to easily put in place the roll and setup the bale tying system.

Depending on the chosen monitor, any wrapping issues can be communicated by the display.

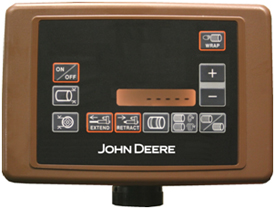

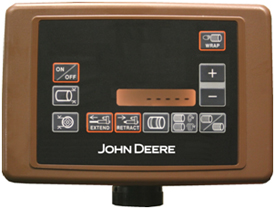

Limited buttons

The BaleTrak Easy has been specially designed for small and medium farms and is focused on the following essential functions:

Limited buttons

The BaleTrak Easy has been specially designed for small and medium farms and is focused on the following essential functions:

Advanced settings and information on BaleTrak display

The BaleTrak display is offered as an option on the F441M Baler. The monitor provides the same functions as the BaleTrak Easy, plus additional settings and information:

Advanced settings and information on BaleTrak display

The BaleTrak display is offered as an option on the F441M Baler. The monitor provides the same functions as the BaleTrak Easy, plus additional settings and information:

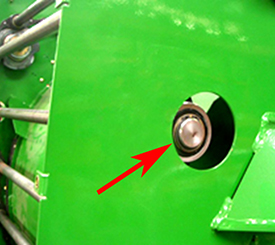

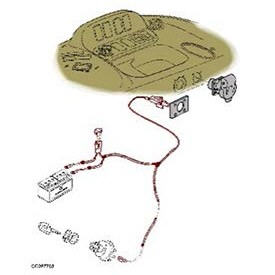

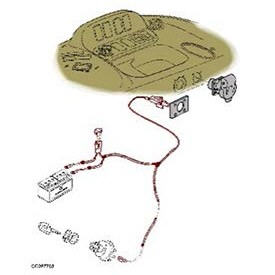

Battery wiring harness

For tractors that do not feature the 12-V, three-pole COBO® outlet, a universal battery harness is provided as an attachment. This electrical harness is linked to the tractor’s battery and delivers the 12-V power to the monitor through a standardized plug.

The battery wiring harness is only available as bundle to retrofit multiples tractors.

Battery wiring harness

For tractors that do not feature the 12-V, three-pole COBO® outlet, a universal battery harness is provided as an attachment. This electrical harness is linked to the tractor’s battery and delivers the 12-V power to the monitor through a standardized plug.

The battery wiring harness is only available as bundle to retrofit multiples tractors.

Versatility and performance provided by choice of MultiCrop bale chamber

MultiCrop gate option offers a versatile solution

F441M with MultiCrop tailgate combines advantages of rolls and conveyor technologies

F441M with MultiCrop tailgate combines advantages of rolls and conveyor technologiesConveyor technology at its best

Noise absorber makes conveyer silent

Noise absorber makes conveyer silent- Bad conveyor tracking caused by foreign objects

- Rails protect the conveyor chains from stones caught in the crops. The stones can be released by opening the tailgate

- Steel-on-steel contact, creating traditional conveyor noise.

- The MultiCrop tailgate decreases noise by having rubber conveyor tracks that absorb most of the noise and vibration.

Reduced maintenance increases uptime

Tensioner optimizes chain lifespan

Tensioner optimizes chain lifespan Slats can be easily changed

Slats can be easily changedSimple feeding with proven technology provides a long and quiet ride

Cam track design offers the best versatility

Left – pickup with cam track / right – cam-less pickup

Left – pickup with cam track / right – cam-less pickup Four tine bars match good picking capacity

Four tine bars match good picking capacity High-capacity (HC) rotor limits plugging risk

Left – HC rotor / right – classic rotor design

Left – HC rotor / right – classic rotor design- Large-diameter rotor to provide high feeding capacity

- Limited distance from pickup to rotor tines to reduce plugging

- Reduced number of bearings and distributed loads along the rotor to increase reliability

- Hardox® wear plate tines to provide high resistance to wear

RotoFlow HC and MaxiCut™ HC 13 rotors are available on the F441M

RotoFlow HC and MaxiCut™ HC 13 rotors are available on the F441MAdvanced drop floor or simple rotor wrench offer unplugging choice

Exclusive drop floor removes the worst plugs

Exclusive drop floor removes the worst plugs Rotor wrench offered as an economical solution for RotoFlow HC Premium

Rotor wrench offered as an economical solution for RotoFlow HC PremiumUser-friendly and efficient tying system provide quality bale

Easy net roll loading

Loading ramp assists roll handling

Loading ramp assists roll handlingSimple and easy net tracking

Very simple net tracking

Very simple net trackingEasy access to platform

Convenient ladder access from both sides

Convenient ladder access from both sidesMonitor has simple and effective display

BaleTrak™ Easy monitor manages essential functions

Limited buttons

Limited buttons- On and off

- Bale size setting

- Net and/or twine selection

- Net and/or twine settings (number of turns, twine spacing, twine space to edges)

- Manual tying process launch

- Manual net system actuating

- Current bale size

- Tying status

- Total bale count

- Resetable bale count

BaleTrak monitor fits demanding user expectations

Advanced settings and information on BaleTrak display

Advanced settings and information on BaleTrak display- Independent right and left space from twine end to bale edge

- Bale size setting monitoring

- Twine feeding monitoring

- Full icon description, such as gate status, tying mode, tying status, bale status, battery status, stop alarm.

- Five resettable bale counter options

- Four factory presets for the wrapping cycle, plus one customizable

Monitor supports

Monitor supports are ordered independently from the monitor. In order to be easily teamed to the tractor, two supports are proposed:- Monitor support for John Deere 5XXX/6XXX/7XXX Series Tractors

- Universal monitor support – John Deere 5XXX/6XXX/7XXX Series Tractors excepted (clamped)

Battery wiring harness delivers 12-V power to the monitor

Battery wiring harness

Battery wiring harnessOffers and Discounts

Related Products

Product Information & Support

You May Also Be Interested In

Product features are based on published information at the time of publication. Product features are subject to change without notice. Contact your local John Deere dealer for more information.