- Lawn & Garden

- Agriculture

- Construction

- Landscaping & Grounds Care

- Golf & Sports Turf

- Forestry

- Engines & Drivetrains

- Government & Corporate Sales

- View All Equipment

- View Used Equipment

- Parts

- Manuals & Training

- Warranty & Protection Plans

- Expert Check

- John Deere Connected Support™

- StellarSupport™

- Recalls

- Safety

- Utility Tractors (23-195 Engine HP)

- Specialty Tractors (75-155 Engine HP)

- Row Crop Tractors (145-410 Engine HP)

- 4WD and Track Tractors (390-640 Engine HP)

- Utility Tractors Attachments & Accessories

- Tillage

- Combine Harvesters

- Cotton Harvesters

- Sugar Harvesters

- Hay & Forage

- Planting Equipment

- Seeding Equipment

- Gator™ Utility Vehicles

- Gator™ Attachments & Accessories

- Loaders for Tractors

- Scraper Systems

- Sprayers

- Precision Ag Technology

- Home & Workshop Products

- Used Agriculture Equipment

- INDUSTRIAL DIESEL ENGINES

- Final Tier 4/Stage V

- Interim Tier 4 / Stage III

- Tier 3/Stage III

- Tier 2 and Lesser Regulated

- MARINE ENGINES

- Commercial/Workboat

- Recreational/Pleasure Craft

- GENERATOR DRIVE ENGINES

- Standby/Stationary

- Prime/Portable

- DRIVETRAIN EQUIPMENT

- Pump Drives

- Transmissions

- Axles

- Planetary Gear Drives

- Vehicle Electrification

- TRACTORS & MOWERS

- Ride-On Mowers

- Utility Tractors (22.4-140 Engine HP)

- Specialty Tractors (75-155 Engine HP)

- Residential ZTrak™ Zero-Turn Mowers

- Commercial Mowers

- CONSTRUCTION

- Backhoes

- Compact Track Loaders

- Dozers

- Skid Steers

- Motor Graders

- Wheel Loaders

- UTILITY VEHICLES & ACCESSORIES

- Gator™ Utility Vehicles

- Gator™ Utility Vehicles Attachments & Accessories

- ATTACHMENTS & ACCESSORIES

- Attachments, Accessories & Implements

- Home & Workshop Products

- Front-End Loaders for Tractors

- Application Equipment

- Attachments, Accessories & Implements

- Backhoes

- Dozers

- Engines

- Forwarders

- Gator™ Utility Vehicles

- Hay & Forage

- Combine Harvesters

- Cotton Harvesters

- Sugar Harvesters

- Home & Workshop Products

- Motor Graders

- Mowers

- Planting Equipment

- Precision Ag Technology

- Scraper Systems

- Seeding Equipment

- Skidders

- Sprayers

- Swing Machines

- Tillage

- Tractors

- Home

- s760 combine

S760Combine

- Combine Advisor™ package helps to set, optimise and automate main combine functions when conditions change

- Fully automated yield sensor calibration with ActiveYield™ supplies accurate data with no time spent calibrating

- Comfortable S700 cab is common with tractors and sprayers for ease of use

- Continued quality manufacturing of S-Series combines maximises uptime and productivity

Features

New for model year 2021 S700 Series Combines

S700 Series Combines

S700 Series Combines

The S700 is one of the most automated combines on the market today. For model year 2021, John Deere introduced several new additions to improve harvesting performance and grain quality.

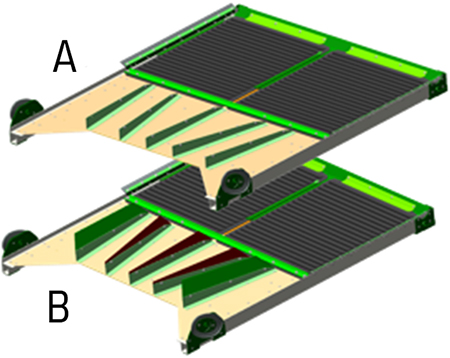

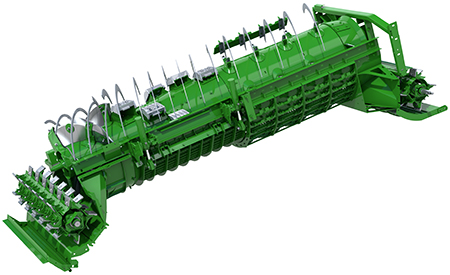

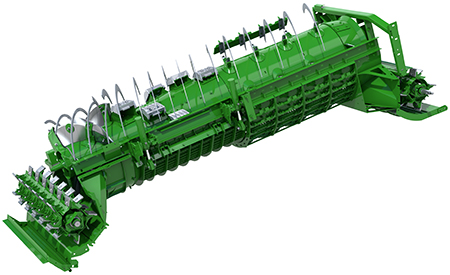

HDX and HDR Series Drapers for S700 Series

Benefits of draper belt combined with hinged frame design and extended frame

Benefits of draper belt combined with hinged frame design and extended frame

Wider header sizes demand new requirements. The newly developed HDX (Hinged Draper Extended Frame) and HDR (Hinged Draper Rigid Knife) Series feature the benefits of a draper header with a hinged frame design to deliver unsurpassed ground contour following, making sure you harvest what you plant. The HDX Series with its 1200-mm (47.2 in.) extended frame has been specifically designed for European small grain and rapeseed conditions. The grain-saver belt saves free grain, reducing header losses. With the increased reel range of up to 559 mm (22 in.), fore/aft movement allows grain to sweep across the cutterbar. The fingered top crop conveying auger in combination with quick attachable rape side knives make the HDX Series the best performing small grain header in the market.

S700 grain tank updates

Large toolless grain tank hatch

Large toolless grain tank hatch

The updated auger elbow and turret deliver about 23 cm (9 in.) more clearance on 7,9-m (26-ft) unloading augers and about 30-cm (11.8 in.) more clearance on 8,7-m (28,5-ft) unloading augers over the grain cart.

With model year 2021, all grain tanks for S-Series Combines feature large toolless grain tank hatches to decrease the time and effort required for tank cleanout between crops.

Unloading auger configurations for model year 2021

The additional 7,9-m (26-ft) unloading auger options on the S760 model, the S770 model, and the S780 HillMaster™ model deliver more flexibility for producers to pair the right unloading auger length with their headers.

| Model | Unloading auger length options | |||

| S760 | 5,6 m (18,5 ft) rigid | 6,9 m (22,5 ft) rigid and foldable | 7,9 m (26 ft) rigid and foldable | — |

| S770 | 5,6 m (18,5 ft) rigid | 6,9 m (22,5 ft) rigid and foldable | 7,9 m (26 ft) rigid and foldable | — |

| S780 | — | 6,9 m (22,5 ft) rigid and foldable | 7,9 m (26 ft) rigid and foldable | 8,7 m (28,5 ft) rigid |

| S780 HillMaster | — | 6,9 m (22,5 ft) rigid and foldable | 7,9 m (26 ft) rigid and foldable | — |

| S790 | — | 6,9 m (22,5 ft) rigid and foldable | 7,9 m (26 ft) rigid and foldable | 8,7 m (28,5 ft) rigid |

*NOTE: Overall machine height exceeds 4 m (13,1 ft) by 49 mm (1,9 in.).

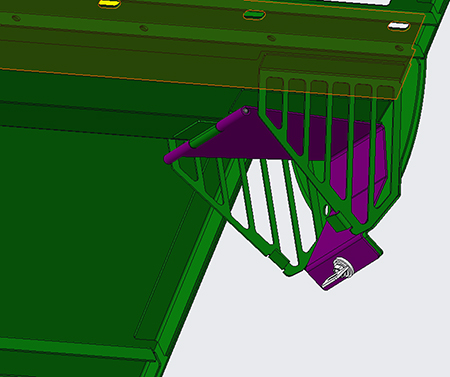

Factory-installed sidehill performance package

Current return pan (A) and sidehill kit (B)

Current return pan (A) and sidehill kit (B)

Model year 2021 sidehill and regular pan

Model year 2021 sidehill and regular pan

With model year 2021, there will be a revised sidehill performance package available that comes factory installed for the best performance in sidehill conditions.

Return pan:

For model year 2021, the return pan design will look similar to regular machines and machines that will be equipped with the factory-installed sidehill package. The updated design of the return pan will have five large dividers for the best performance in leveled and hilly conditions.

Front chaffer dividers:

On the model year 2021 factory-installed sidehill kit, there will not be any front chaffer dividers installed. For most conditions, front chaffer dividers will not be required and may decrease performance. In case of conditions that require front chaffer dividers, they can be ordered through Parts.

Chaffer dividers and flaps:

Factory-installed long dividers and inner rubber flaps

Factory-installed long dividers and inner rubber flaps

Dealer-installed outer rubber flaps

Dealer-installed outer rubber flaps

The sidehill package features long dividers and inner rubber flaps factory installed. Only the outer six rubber flaps are installed at the dealership.

Programmable control center

Generation 4 CommandCenter™ Display – make it your own

Customise and store screens of the Gen 4 CommandCenter to suit the way you work

Customise and store screens of the Gen 4 CommandCenter to suit the way you work

You’ll find the S700 Combines easier to operate the way you want it to. All the controls are integrated in one place. You won’t find yourself looking around the cab for different displays or reaching for out-of-the-way switches. Everything is logically grouped in one place. The Generation 4 display has been completely redesigned with the same, easy-to-use navigational features as a smartphone. Swipe to move from screen to screen, select apps you want to run, and customise screen layouts to suit the way you want to work. John Deere also rethought the navigation process, reducing the number of clicks to get you to where you need to be.

The ergonomic design of the CommandPRO™ control handle brings the same seamless experience as multifunction game controllers. Now you can control all the main functions from your hand. What’s more, you can personalise it like never before with seven programmable buttons.

And, best of all, you can switch between screens on the display by turning a wheel on the hydro handle – no need to take the hand off in critical situations when you have to have manual control (e.g., in down crop or while cutting the headland).

The CommandPRO control handle

CommandPRO control handle has seven programmable buttons

CommandPRO control handle has seven programmable buttons

When they were designing the CommandPRO control handle control, our engineers looked at every hand-held controller from game players to aircraft. We listened to our customers’ demands as well. They wanted more programmable features to customize their harvesting. The result is over 30 percent more functions than any other combine controller.

As soon as your hand grips the CommandPRO control handle, you know this is very different from any other machine you have operated. It fits like a glove. The different buttons are in the perfect position. Even the scrolling wheel at the back is comfortable to the touch. It all feels so completely natural. You can imagine closing your eyes and being able to operate it perfectly. Man and machine working in harmony.

Store the individual CommandPRO settings of your operators using the time-saving setup control feature

Store the individual CommandPRO settings of your operators using the time-saving setup control feature

Choose the way you want to work: 700X header extension/retraction, 700D belt speed, grain tank cover opening, unloading auger folding, chopping spread direction, feederhouse tilt, and much, much more.

Individual buttons can be programmed via the touch screen on the Gen 4 CommandCenter 4600 Display.

If you have different operators, they will love the fact that they can all store their own individual settings for the CommandPRO control handle and display using the time-saving setup control feature.

Combine Advisor™

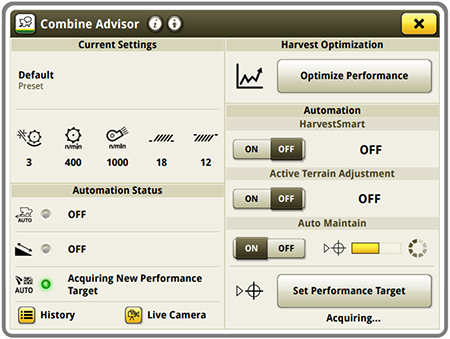

Combine Advisor is a suite of technologies designed to maximize harvesting profits. The features help the operator set and optimize the S700 Combine and then automates the combine to maintain performance target as conditions change. Purchasing Combine Advisor grants access to the Combine Advisor application, which houses three automation technologies: HarvestSmart™ system for automation of feed rate, Active Terrain Adjustment™ system for terrain change management, and Auto Maintain with ActiveVision™ cameras for crop condition change management.

Combine Advisor also provides easy navigation of the S700 set and optimize features: harvest settings application for initial set up and setting storage, VisionTrak system for monitoring losses, and Optimize Performance for step-by-step guidance of combine setting optimization. Once John Deere Combine Advisor is set into motion, the operator will experience ease-of-use benefits coupled with increased productivity.

Code |

Description |

1963

|

Combine Advisor Base features, plus Active Terrain Adjustment and Combine Advisor. Includes ActiveVision cameras.

Base features include Optimize Performance, TouchSet™ system, VisionTrak, HarvestSmart, and engine speed management. HarvestSmart and engine speed management only included with code 2020 (ProDrive™ transmission). Engine speed management only available with Final Tier 4 (FT4) engines. |

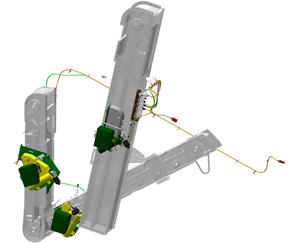

Combine Advisor hardware and software

Combine Advisor bundles are available for model year 2018 and future models. The bundles include ActiveVision cameras, harnesses, Auto Maintain, and software.

Dealer installation instructions are included, as weldments and drilling are required. The process will most likely take around 10 hours of labor.

| Bundle | Description |

BXE11034 |

Combine Advisor retrofit bundle for S760 and S770 Combines Also requires BXE10948 Active Terrain Adjustment bundle if the combine is not already equipped with code 1961 (base features + Active Terrain Adjustment) |

| BXE11035 | Combine Advisor retrofit bundle for S780 and S790 Combines Also requires BXE10948 Active Terrain Adjustment bundle if the combine is not already equipped with code 1961 (base features + Active Terrain Adjustment) |

Combine Advisor retrofit bundle components

Combine Advisor retrofit bundle components

Combine Advisor video

- John Deere Combine Advisor Package (full video)

- The following videos are segments of the above full version:

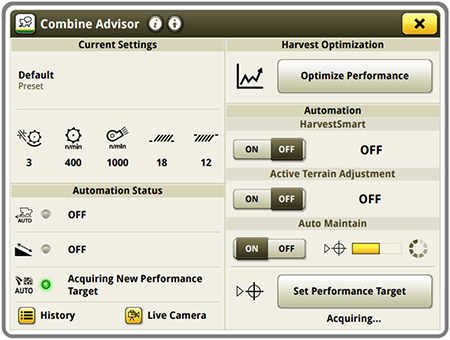

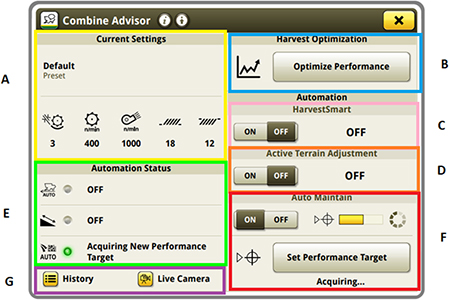

Combine Advisor application

Combine Advisor run page

Combine Advisor run page

The Combine Advisor application provides the tools needed to set the combine to get the most out of it and automatically adjust settings to maintain optimum performance. Inside this application on the 4600 CommandCenter™ Display, the operator will find many tools including easy-to-adjust current machine settings, sensitivity settings for automation, application status indicators, automation activity history overviews, and live feeds of grain analysis cameras.

Additionally, the operator can access Optimize Performance, activate the three automation technologies, and set the performance targets the machine will automatically adjust to maintain.

Feature benefits:

- Efficient combine operation with a one-page application for animation technologies

- Improved combine settings management with settings, sensitivities, and status information all on one reference page

- Reduced operator training and efficient, easy control of harvest settings through an intuitive run page and user interface

Functionality:

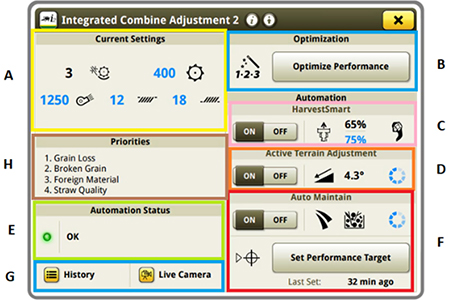

ICA2 run page, model years 2018 and 2019

ICA2 run page, model years 2018 and 2019

Combine Advisor run page changes beginning with model year 2020

Combine Advisor run page changes beginning with model year 2020

| ICA2 run page, model year 2018 | Combine Advisor run page, model year 2020 |

| Section A (yellow highlight): takes the operator to the current settings for concave clearance, rotor speed, fan speed, chaffer clearance, and sieve clearance, giving quick access to critical combine adjustments. | Section A (yellow highlight): takes the operator to the current settings for concave clearance, rotor speed, fan speed, chaffer clearance, and sieve clearance, giving quick access to critical combine adjustments. It also shows the currently selected preset. |

| Section B (blue highlight): the Optimize Performance button helps the operator optimize combine performance. | Section B (blue highlight): the Optimize Performance button helps the operator optimize combine performance. |

| Section C (pink highlight): the HarvestSmart system automates ground speed control during harvest to maintain a constant crop load. | Section C (pink highlight): the HarvestSmart system automates ground speed control during harvest to maintain a constant engine load. The Manage Target with Grain Loss setting enables an automatic target adjustment based on loss levels. |

| Section D (orange highlight): the Active Terrain Adjustment system produces better grain quality and fewer losses while controlling tailings volume when harvesting up and down hills. | Section D (orange highlight): the Active Terrain Adjustment system produces better grain quality and fewer losses while controlling tailings volume when harvesting up and down hills. |

| Section E (green highlight): automation status | Section E (green highlight): Combine Advisor system – HarvestSmart, Active Terrain Adjustment, and Auto Maintain. |

| Section F (red highlight): Auto Maintain monitors the combine and makes adjustments to maintain the performance at the operator-set performance target. | Section F (red highlight): Auto Maintain monitors the combine and makes adjustments to maintain the performance at the operator-set performance target. |

| Section G (purple highlight): Auto Maintain also uses the buttons in section G to allow a glimpse into live views of the clean grain and tailings elevators and allows operators to use an analyzer function to see what Auto Maintain is seeing. It also shows a list of adjustments made by Auto Maintain and Active Terrain Adjustment. **In sections C, D and F select the screen area to see additional sensitivity settings for each system. |

Section G (purple highlight): Auto Maintain also uses the buttons in section G to allow a glimpse into live views of the clean grain and tailings elevators and allows operators to use an analyzer function to see what Auto Maintain is seeing. It also shows a list of adjustments made by Auto Maintain and Active Terrain Adjustment. **In sections C, D and E select the screen area to see additional sensitivity settings for each system. |

| Section H (brown highlight): indicates the operator’s priorities for automation | — |

|

|

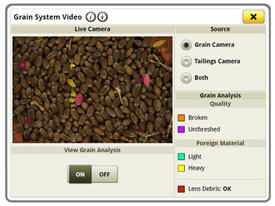

Grain analysis live view

Grain analysis live view

|

Combine Advisor with Auto Maintain is available as a factory-installed option on combines since model year 2018. Auto Maintain is compatible in corn, soybeans, wheat, canola, and barley. Retrofit kits, BXE11034 and BXE11035 are available. Please refer to that section for more information. |

Auto Maintain

Auto Maintain with ActiveVision cameras is technology that works to automatically adjust five primary S700 Combine settings to maintain the user set performance target. When harvesting corn, soybeans, wheat, canola, or barley, the combine will maintain the performance of everything from grain loss and grain quality, to foreign material in the grain tank. The ActiveVision cameras, along with grain loss monitors, are specifically designed to identify the impact of crop condition changes and adjust the combine to maintain the performance target, allowing the operator to focus on other challenges of harvest.

Feature benefits:

Simplify harvest by automating the critical workload of constantly managing combine settings when conditions change

Increase productivity by allowing ActiveVision cameras to identify and address tough-to-spot problems such as cracked grain

Provide flexibility in planning overall business and increase the efficiency of the combine independent of operator experience

Combine Advisor run page

Combine Advisor run page

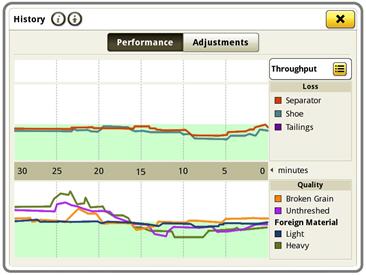

Functionality

Auto Maintain looks at the level at which the combine is performing, sets that as the goal, and automates combine settings to continually hit the target performance goal over time. Auto Maintain uses existing sensor inputs along with the ActiveVision cameras to make decisions for accurate combine adjustments. It does not use grain moisture as an input, however. Auto Maintain is able to hit the target goal by automatically making adjustments to the threshing speed, concave clearance, chaffer clearance, sieve clearance, and fan speed. The ActiveVision cameras have been trained to analyze the clean grain and tailings material and input that analysis into the Auto Maintain system. Auto Maintain will show the operator how it has been performing with a constantly updating historical graph of losses, grain quality, and foreign material in the clean grain. The green-shaded area below indicates the performance targets set. The colored lines show the ongoing levels of losses and quality. For example, the green, purple, and orange lines below show a period of time outside of the green-shaded acceptable area. Auto Maintain recognizes this and makes the appropriate adjustments to meet the set targets.

Historical Auto Maintain performance graph

Historical Auto Maintain performance graph

The ActiveVision cameras can detect broken and unthreshed grain. The cameras will also detect lightweight and heavy foreign material to make the appropriate combine settings changes. The system provides a live feed of both the grain and tailings cameras and will highlight the parameters outlined to make it easier to analyze. The live view and historical graphs update constantly, and the cameras will even tell the operator if there is debris on the lens.

Additional Combine Advisor features

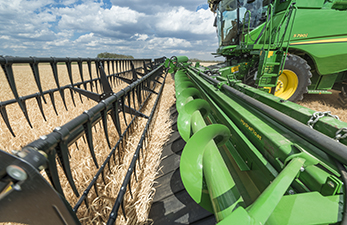

High-performance header

Where profitability begins

Small improvements in grain yields bring big increases in profits. That’s why John Deere offers a comprehensive range of headers so you can find the perfect match for your crops and your combine. Choose from traditional auger designs (600R, 600F, or 700X) to active crop feeding with belts (700D, RDF Series [Rigid Draper Flex Knife], or the HDX [Hinged Draper Extended Frame] and HDR [Hinged Draper Rigid Knife] Series) in a wide range of widths up to 13,7 m (45 ft).

600R and 600F

More than 650,000 headers have been built, making it a proven and field-tested combine header

More than 650,000 headers have been built, making it a proven and field-tested combine header

More than 650,000 600R headers have been built, making it a proven and field-tested combine header. It has many premium features, including stainless-steel feed plates, a large-diameter auger, and a linear knife drive. The 600F features a flexible cutterbar which lets you drive faster and cut cleaner on uneven ground and helps reduce losses in down or tangled crops. A 600R or 600F with rape seed attachment has the lowest amount of losses during rape harvest due to the longest distance from auger to the knife.

700X

700X features a 710-mm (28-in.) adjustable table length, the longest on the market

700X features a 710-mm (28-in.) adjustable table length, the longest on the market

The 700X is the ultimate header if you’re harvesting a variety of crops. It has an unbeatable conversion time of under 3 minutes without the need for any tools. It has one of the longest tables on the market (1,200 mm [47.2 in.]) for a variable header, so grain losses are minimal. You can also adjust it by up to 710-mm (28-in.) from the comfort of the cab to respond to changing conditions on the go.

700D and RDF Series

Head-first active crop feeding with a belt instead of an auger

Head-first active crop feeding with a belt instead of an auger

RDF Series Header with flexible knife

RDF Series Header with flexible knife

The 700D Header promotes head-first feeding for smooth crop flow. Its lightweight design reduces ground pressure and the hydraulic tilt angle adjustment adapts quickly to down crop. The 300-mm (11.8-in.) minimum cutting height leaves fields clean, and the knives and fingers are specially hardened to work closely to the ground. Fully integrated into the combine display, it’s also rapeseed capable thanks to the 1,650-Nm (1,217-lb-ft) side clutch and 450-mm (17.7-in.) top auger. Mechanical side knives and a sealing kit option are all it needs to be rapeseed ready.

The RDF Series offers all the advantages of active feeding of the 700D with the added benefit of a flexible knife with up to 190-mm (7.5-in.) travel range. Instead of using hinged wings, it flexes over the whole width of the cutterbar to minimise crop losses in uneven ground.

HDX and HDR Series

Benefits of draper belt combined with hinged frame design and extended frame

Benefits of draper belt combined with hinged frame design and extended frame

Wider header sizes demand additional requirements. The HDX (Hinged Draper Extended Frame) and HDR (Hinged Draper Rigid Knife) Series feature the benefits of a draper header with a hinged frame design to deliver unsurpassed ground contour following, making sure operators harvest what was planted. The HDX Series with its 1200-mm (47.2-in.) extended frame has been specifically designed for various small grain and rapeseed conditions. The grain saver belt saves free grain, reducing header losses. With the increased reel range of up to 559 mm (22 in.), fore/aft movement allows grain to sweep across the cutterbar. The fingered top crop conveying auger in combination with quick attachable rape side knives make the HDX Series to the best performing small grain headers in the market.

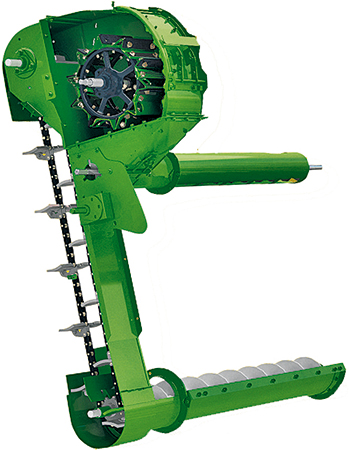

The single rotor

Less than 0.5 percent broken grain

Instead of splitting the crop flow up into two streams, it keeps a single crop flow which consumes less power

Instead of splitting the crop flow up into two streams, it keeps a single crop flow which consumes less power

The single rotor of the S-Series gives you a clear advantage over other, more traditional and hybrid systems. Instead of splitting the crop flow up into two streams, it keeps a single crop flow which consumes less power.

This is because the large diameter of the rotor generates higher inertia than smaller rotors running at lower rotational speeds. The crop also passes over the threshing areas multiple times compared to a tangential threshing system. Research has shown that even without optimisation of the combine, broken kernels do not exceed 0.5 percent. It’s one of the reasons why the S-Series is the combine of choice for many seed producers.

It doesn’t matter if you’re harvesting large areas of a single crop or moving from crop to crop, the S-Series offers true, multi-crop capability. Tested in 36 different crops, you can customise every single component from the header through to the rotor and residue management system. Crop conversion is fast and easy with excellent access to the rotor.

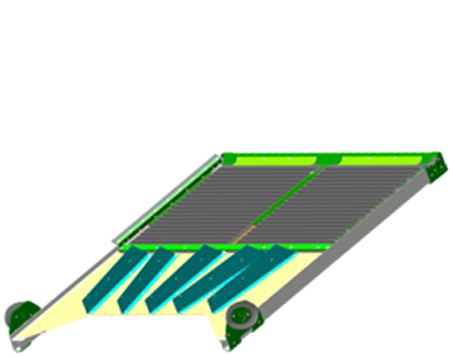

Three equal crop streams

Three equal crop streams

Three equal crop streams

270-degree feeding ensures a smooth transition from a tangential crop flow from the beater to an axial crop flow for the rotor. The large space in the front of the rotor makes this transition easier and less power consuming, leaving more power for threshing. Unlike hybrid systems, there is no need to split the crop flow and squeeze it through a narrow opening which can cause plugging.

Active Concave Isolation

This maintains consistent concave clearance for better performance in high yield crops or when there is uneven feeding. It enables the concave to be set much wider for more crop-on-crop threshing. Compared to other mechanical systems, this enables a non-stop overload protection.

Efficient separating

Efficient separating in the rear section

Efficient separating in the rear section

The rear section of the rotor is predominantly where separation takes place. Depending on the conditions. there’s a choice of two rotors: the TriStream™ rotor and the variable stream rotor.

The TriStream rotor is recommended for lower yielding crops.

The variable stream rotor is recommended for high yield, rice, or when crops are damp, wet, and green, or in tough straw. For these conditions, the rotor has been designed with a more conical shape at the front. The amount of rotations the crop performs can also be changed from inside the cab. This allows the operator to easily vary the threshing intensity depending on whether they are experiencing moist or dry conditions throughout the day. This also helps improve the straw quality.

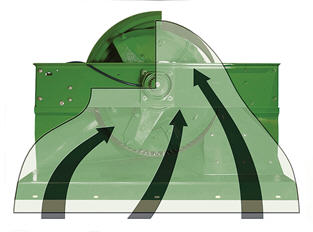

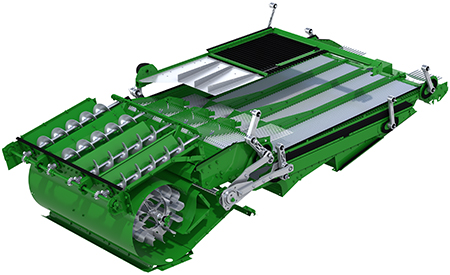

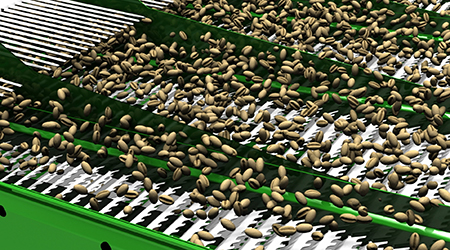

Dyna-Flo™ Plus cleaning shoe

Maximizing cleaning time and minimizing losses

The large air volume paired with the new air flow and the large sieve area makes additional slope compensating features obsolete

The large air volume paired with the new air flow and the large sieve area makes additional slope compensating features obsolete

5.9 m² (63.5 sq ft) of sieve area makes this one of the largest cleaning shoes on the market. Crop stays on the sieves for longer, maximizing cleaning time and minimizing losses.

The fan delivers up to 740 m³ (26,133 cu ft) of air per minute and was designed to evenly distribute the air over the entire width. Excessive suction on the side is minimized through targeted sealing of the openings, while more air is taken in through air ducts in the middle.

The large air volume paired with the new air flow and the large sieve area makes additional slope compensating features obsolete.

More effective two-stage pre-cleaner

An additional raised front chaffer is a unique feature of the Dyna-Flo Plus. This helps thin the crop mat and distribute it across both the front and rear of the cleaning shoe. It also cleans up to 40 percent of the free grain before it reaches the main chaffer.

Easily optimized cleaning system

We’ve completely redesigned the cleaning system so it’s less sensitive to operator adjustment. This means the operator doesn’t have to constantly make adjustments in changing crop conditions. No pre-chaffer adjustments are required at all, and it’s much easier to optimize the fan.

The self-cleaning conveyor augers ensure active crop flow on slopes and under tough harvest conditions. So even if you are harvesting on hillsides or in wet and sticky conditions (e.g., rape seed or corn), you can be sure that the cleaning shoe is evenly loaded.

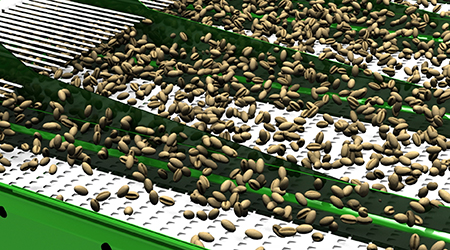

Active tailings system

Lowering losses

A mini threshing drum with real rasp bars and concave separate kernels still sitting in ears

A mini threshing drum with real rasp bars and concave separate kernels still sitting in ears

The active tailings system is a major performance-enhancing feature of the S780 through S790 models. It increases the capacity of the combine by taking care of tailings separately and makes the overall setup and adjustment easier. The net result is more performance and better grain quality with lower losses, as well as improved straw quality and reduced fuel consumption.

A mini threshing drum with real rasp bars and concave separate kernels still sitting in ears. Like the rest of the threshing system, this is designed to be gentle to avoid grain damage. The concave itself has two settings controlled by a spring lever for easy switching between corn and small grain crops.

The material is returned to the top of the chaffer by an auger. The opening at the bottom of the auger is triangular so material is spread evenly instead of it dropping in one spot. This helps avoid any potential overload of the cleaning system.

The system acts as a re-thresher which takes care of the tailings. This allows the concave to be opened wider which lowers both the power requirement and fuel consumption. At the same time, it has the added benefit of improving straw quality as the crop is not so compressed between the concave and the rotor. The reduction in tailings also allows the bottom sieve to be opened further, which increases capacity even more.

Active Terrain Adjustment™ system

On downhill slopes, the chaffer and sieve close while the fan speed increases to keep grain from pushing towards the front of the machine

On downhill slopes, the chaffer and sieve close while the fan speed increases to keep grain from pushing towards the front of the machine

Depending on the gradient of the slope, Active Terrain Adjustment automatically adjusts all the important cleaning shoe settings: fan speed, chaffer, and sieve. It also takes into account the type of crop that is being harvested. For instance, rape seed is particularly sensitive to fan speed changes, so the system adjusts the chaffer and sieve settings first before adjusting the fan speed, whereas corn isn’t as sensitive to wind speed.

Active Terrain Adjustment results in consistently low grain losses on rolling terrain. It also reduces the amount of tailings and delivers cleaner grain to the tank. What’s possibly most important of all, it takes the pressure off of the operator to make constant adjustments.

Uphill slopes

Active Terrain Adjustment – uphill slopes

Active Terrain Adjustment – uphill slopes

Going up a hill, both the chaffer and sieve are opened while the fan speed is reduced to keep grain from being lost through the rear of the combine. In this situation, the cleaning system performance increases by up to 50 percent on inclines of up to 16 degrees.

Downhill slopes

Active Terrain Adjustment – downhill slopes

Active Terrain Adjustment – downhill slopes

On downhill slopes, the chaffer and sieve close while the fan speed increases to keep grain from pushing towards the front of the machine. This reduces the volume of tailings by as much as 50 percent, resulting in a cleaner grain tank sample. It also saves you from penalties of dirty grain samples when you sell at the elevator.

Highly accurate yield measurement

Data you can trust

The yield data is displayed on the Gen 4 CommandCenter™ 4600 Display and can be wirelessly transferred to the Operations Center on MyJohnDeere.com.

The yield data is displayed on the Gen 4 CommandCenter™ 4600 Display and can be wirelessly transferred to the Operations Center on MyJohnDeere.com.

ActiveYield™ management is another automated John Deere innovation that saves time and improves harvesting performance. Now you no longer have to carry out time-consuming manual calibrations and double-weighing of trailers to get accurate yield measurement results.

Three sensors

Three sensors

Three sensors inside the tank automatically measure the change in weight as the grain tank fills. The system compares the measurement with those of the yield and moisture sensors to calibrate the yield sensor on a permanent basis. The biggest advantage of the system is that it generates a calibration curve at various speeds and throughput levels with a number of calibration points. This is a task that is usually not carried out manually in the field by operators.

What’s more, the system is designed to compensate for shifting grain when harvesting on slopes or if the operator performs a full stop. It even compensates for wear and tear of the elevator chain over several harvest seasons. It’s attention to detail like this that gives you the confidence to rely on the results year after year.

Better yield mapping

Three sensors in the tank measure the weight of grain.

Three sensors in the tank measure the weight of grain.

ActiveYield transforms the accuracy of yield mapping, as today 96 percent of customers only complete a single point or perform no calibration at all – only 4 percent complete the recommended multi-point calibration. This improves the accuracy of precision farming as it allows better control of inputs for variable rate seeding, fertiliser application, and crop care.

Now there’s no need to interrupt the harvesting chain for regular weighing in different crops and conditions.

Plus, you don’t have to worry if there’s no weight bridge within close proximity.

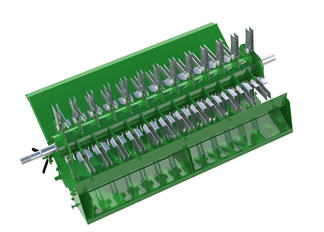

HillMaster™ system – Level performance on slopes

Full performance on hills

Full performance on hills

Slopes up to 7 percent

The secret to a stable hillside performance is the Dyna-Flo™ Plus cleaning shoe. It all starts with the conveying augers, which move the material evenly onto the cleaning shoe. There’s no chance of it sliding down or moving to one side.

Once the material reaches the cleaning shoe, the real innovation shows. The whole shoe is longer than before and is also longer than comparable concepts from other brands. This means the crop stays longer on the chaffer and sieve. The longer it stays, the more time it has to be separated and the less chance there is of it going out the back of the combine, which reduces losses. This technology allows operators to cover slopes of up to 7 percent.

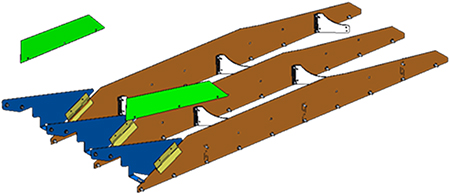

Slopes up to 14 percent

The sidehill performance package for slopes up to 14 percent contains chaffer dividers, grain agitators, and grain pan diverters. These prevent grain from accumulating on one side and help distribute it over the full width of the chaffer. The agitators actively move grain uphill with every stroke, while the dividers and diverters prevent grain from moving downhill on side slopes.

Together with the in-base technology at the cleaning shoe, you can be confident of harvesting in slopes of up to 14 percent without any compromises or grain losses. This simple and reliable solution has no moving parts either, so it’s maintenance and wear free.

HillMaster combine for slopes up to 22 percent

The HillMaster system not only adjusts the chaffer and the cleaning shoe, it levels the whole combine from the feederhouse to the chopper. This means the whole crop flow behaves exactly as if the combine was harvesting on level ground. The grain tank also stays level, which gives you the added benefit of being able to carry a full load even on slopes, saving additional unloading stops. HillMaster won’t just be appreciated when it comes to measuring your yields either. It’s a lot more comfortable for the operator, too.

HillMaster also has the added benefit of keeping the weight distribution even. Without it, the wheels on the downhill side of the combine would experience more load, which would increase soil compaction. By levelling the whole body of the combine, HillMaster shifts the centre of gravity so there’s even ground pressure across all four wheels. This also ensures that the combine has better traction and stability on slopes, which is an important consideration in unstable or wet soils.

Residue management

More flexibility

The direction of spread as well as the width can be conveniently adjusted on the go from the cab

The direction of spread as well as the width can be conveniently adjusted on the go from the cab

There’s a choice of up to three different chopper systems to suit your harvesting operation. Whatever you choose, you can rely on evenly spread, fine-cut straw from the moment you start harvesting, or well-windrowed straw for quality bales.

All systems feature a discharge swap switch to change the offset for the direction of spread to compensate for wind direction. Our premium and intermediate systems are equipped with a 100 knife, extra-fine-cut chopper. This ensures the residue is quickly incorporated into the soil, releasing valuable nutrients for the next planting season.

The premium system is also a real time-saver. You can switch from chop to drop from the cab at the touch of a button. It proves a very useful feature at headlands or parts of the field which shall be treated differently when you can instantly switch from dropping to chopping.

Deluxe

- 44 rotating and 44 stationary counter knifes

- Two manually adjustable speeds for small grain and corn

- 3-minute manual conversion between chopping and dropping

- Chaff is distributed through the line-break chopper or is dropped below the windrow. No separate chaff spreader needed.

- No overshot beater and therefore less power required and less weight compared to premium chopper

- Electrically adjustable vane tailboard for spread width up to 9 m (29.5 ft)

Deluxe chopper with 44 rotating and 44 stationary counter knifes

Deluxe chopper with 44 rotating and 44 stationary counter knifes

Intermediate

- 100-knife chopper producing one of the finest cuts of straw on the market

- Two manually adjustable chopper speeds for small grain and corn

- 3-minute manual conversion between chopping and dropping

- Chaff is distributed through the chopper in chopping mode or dropped below the windrow in windrow mode; with this chopper, you cannot spread the chaff when you are windrowing

- No overshot beater and therefore less power required and less weight compared to the Premium chopper

- Electric vane tailboard with low power requirement up to 9-m (29.5-ft) cutting width or Advanced PowerCast™ tailboard with two hydraulically driven, enclosed discs (recommended above 9-m [29.5-ft] header width).

Premium

- 100-knife chopper, producing one of the finest cuts of straw on the market

- Two manually adjustable chopper speeds for small grain and corn

- Chop-to-drop from cab – switch from chopping straw to dropping windrows at the touch of a button

- In chopping mode, chaff and straw are distributed through the chopper. In dropping mode, chaff is distributed through the chopper and straw is windrowed. No separate chaff spreader is needed.

- Cleaning shoe blows chaff out to the side, away from the windrow, for better quality bales that are free of chaff

- Electric vane tailboard with low power requirement or Advanced PowerCast spreader (recommended above 9-m [29.5-ft] header width) with two hydraulically driven enclosed discs and a center divider. The pendulum motion of the central wag distributes material evenly immediately behind the combine.

The premium chopper produces one of the finest cuts of straw on the market with 100 knives

The premium chopper produces one of the finest cuts of straw on the market with 100 knives

Advanced PowerCast active spreader

Advanced PowerCast spreader for even distribution

Advanced PowerCast spreader for even distribution

The Advanced PowerCast spreader is the perfect solution for even distribution of chopped straw and can be beneficial especially on cutting widths above 9 m (29.5 ft). Most customers prefer a vane tailboard for cutting widths up to 9 m (29.5 ft). It is a cost-effective solution which spreads evenly in windy conditions due to its low mounting.

This technology also has the added benefit of lower power and fuel consumption. The spreader accelerates the chopped straw as it passes through the vanes for a wider, more even spread of up to 14.5-m (47.6-ft) wide.

John Deere tracks

Large footprint

30 percent larger footprint

30 percent larger footprint

Everyone knows tracks are better than tyres when it comes to unstable ground and muddy conditions, but tracks don’t win in every situation, until now. John Deere tracks keep you harvesting thanks to our unique, updated design. What’s more, the extra-large footprint reduces soil compaction and avoids the need for deep tillage, saving costs all year round.

20 percent more comfort and smoother ride

20 percent more comfort and smoother ride

John Deere has completely rethought the whole concept of tracks from the ground up. The updated design represents a leap in performance in every area:

- 20 percent more comfort and a smoother ride

- 30 percent larger footprint for less compaction

- 50 percent increased durability for lower cost of operation

- Choice of three track widths for different conditions

- 3.49-m (11.45-ft) minimum combine width for narrow roads

- No daily maintenance for more uptime

- Up to 40-km/h (24.85-mph) transport speed on S770 through S790 models

Updated design for excellent performance

Excellent performance

Excellent performance

Our updated design retains all the benefits of our previous tracks: retrofitability, hydraulic suspension, five-point contact technology, positive drive with triangular profile, and a climb-out-of-mud effect:

- Bigger footprint – the tracks are longer compared to the previous design and compared to the design of most competitors. This puts more tread on the ground for better grip, lower soil compaction, and improved fuel economy compared to wheeled machines.

- Narrower width – the footprint of our 61-cm (24-in.) tracks is comparable in many cases to 73.7-cm (29-in.) wide competitor’s tracks, but with the added advantage of a narrower transport width.

All-terrain capability with exceptional ride quality

Triangular design for good ground clearance

Triangular design for good ground clearance

The triangular design provides good ground clearance and has excellent self-climbing properties in unstable ground. The five-point pivot design with small distances between the pivot points and rollers ensure that the tracks tightly follow the ground for better grip. Another advantage is significantly reduced vibration for better ride quality.

Zero maintenance

Apart from being incredibly tough, another advantage of the IPX 2000 material being used is its self-lubricating properties which reduce wear and tear. Sealed gearboxes and bearings also remove the need for regular greasing. All that’s needed is an oil change every 500 hours.

Exceptional grip and long life

Longer wear life

Longer wear life

The track treads are designed with a higher profile for longer wear life. The deep pattern also provides greater grip. They’re self-cleaning thanks to the 55-degree angle between the bars which promotes mud release. Tests show the pattern reduces friction with less heat generated, which reduces wear by as much as 50 percent compared to previous John Deere tracks.

40 km/h (24.9 mph) transport and transmission

Travel quicker and harvest faster

With the S-Series you´ll spend less time travelling to the field and harvest more hectares faster

With the S-Series you´ll spend less time travelling to the field and harvest more hectares faster

On the road, the ProDrive™ transmission gives you transport speeds of up to 40 km/h (24.9 mph) so you’ll get to where you need to be faster. In the field, it delivers more torque and because of its infinitely adjustable speed, you’ll cover more hectares in less time.

The ProDrive transmission is an infinitely variable transmission with two ranges and is included as standard on all S780 through S790 models. Shifting between the ranges is automatic without any stopping and is hardly noticeable.

Producing 64 percent more torque across the entire speed range, ProDrive delivers impressive acceleration on the road. It also helps you maintain top speed for longer when driving up slopes as more power is transmitted through the mechanical part of the transmission.

In the field, ProDrive delivers 95 percent more torque around 6.5 km/h (4 mph) (average harvesting speed), which is enough to comfortably pull you through muddy areas or uphill with a full grain tank. It also includes a differential lock, HarvestSmart™ system, and automatic forward speed management system.

Engine speed management automatically controls the engine’s rpm during road transport. This produces fuel savings of 10-20 percent.

Push-button shifting

With a push of a button you change gears the easy way

With a push of a button you change gears the easy way

The optional push button shift transmission on S760 through S770 models makes changing gear easy. Just push one of the three gear buttons and let the combine do the rest. Stopping is easy, too. The park brake is automatically engaged in the neutral position so there is no need to push a separate hand-brake pedal.

Offers and Discounts

0% p.a. Finance Available* on Combine Parts and Servicing

Related Products

Product Information & Support

You May Also Be Interested In

Product features are based on published information at the time of publication. Product features are subject to change without notice. Contact your local John Deere dealer for more information.