- GOLF COURSE EQUIPMENT

- SPORTS TURF

- INDUSTRIAL DIESEL ENGINES

- MARINE ENGINES

- GENERATOR DRIVE ENGINES

- DRIVETRAIN EQUIPMENT

- TRACTORS & MOWERS

- CONSTRUCTION

- UTILITY VEHICLES & ACCESSORIES

- ATTACHMENTS & ACCESSORIES

Features

HydraFloat™ integrated suspension system improves ground following

Selection dial

Selection dial

Multifunction control handle

Multifunction control handle

The feature of this system is that while sensing on the ground, the operator can, from the cab, change the hydraulic pressure required to float the header over the ground. As ground conditions change, the operator can increase or decrease the flotation capability of the header to match operating conditions.

These features are possible due to the hydraulic design of the system. The operator is able to use the hydraulics of the combine and head to match operating conditions.

The hydraulics add ease of operation because they are integrated into the design of John Deere combines, enabling operators to make in-cab adjustments. They also add productivity, as the operator no longer has to estimate how close the header is to the ground. The operator simply selects the preset height.

The lateral tilt feederhouse is highly recommended for use with 600D Series Draper Platforms.

Maintain excellent visibility to cutterbar while tilting it

Tilt cylinder

Tilt cylinder

Advanced hydro handle

Advanced hydro handle

The cutterbar can be tilted from the cab hydraulically a full 8 degrees while maintaining excellent visibility to the cutterbar throughout the tilt range.

This adjustment allows operators to optimize the cutterbar angle for varying conditions thus extending the harvest day and providing the lowest cut height possible.

For improved ease of use the optional advanced hydro handle can be configured to control the platform tilt.

Dual-knife drive system is timed

Cutterbar epicyclical gearcase

Cutterbar epicyclical gearcase

Knife drive shaft

Knife drive shaft

The unique dual-knife-drive system is timed, creating the smoothest-possible reciprocating knife-drive system currently in the industry. The positive, reliable shaft-driven dual epicyclical in-line knife drives with built-in driveline protection provide operators with the strongest knife-drive system.

Lateral tilt feederhouse enhances 600D HydraFloat™ system performance

HydraFloat allows the operator to change the hydraulic pressure required from the cab to float the header. As ground conditions change, the operator can increase or decrease the flotation capability of the header to match operating conditions. A lateral-tilt feederhouse is highly recommended for use with 600D Series Draper Platforms as it allows operators to obtain the full benefit and capabilities of the automatic header-leveling system on sloping or uneven terrain.

Customer benefit:

- The HydraFloat system has a usable float range of 6 degrees reducing header loss

- Lateral tilt feederhouse adds an additional 4 degrees of lateral tilt, increasing the total float range to 10 degrees, which is unmatched in the industry

- Combined, these features allow operators to harvest on aggressive side slopes or uneven terrain

600D Draper with lateral tilt feederhouse

600D Draper with lateral tilt feederhouse

Selection dial

Selection dial

Theory of Operation:

The hydraulic control adds productivity, as the operator no longer has to estimate how close the header is to the ground. The operator simply selects the preset height from inside the cab.

Together, these two features provide key competitive advantages in performance and ease of operation.

S690 equipped with lateral tilt feederhouse

S690 equipped with lateral tilt feederhouse

All other small-grain draper platforms in the industry utilize either springs or air bags to laterally tilt the platform and follow ground contours. This technology worked well in the past but has always been a reactive technology and not an active technology. The 600D HydraFloat system with integrated header height sensing along with a lateral tilt feederhouse offers unmatched ground-following capability that no other draper platform can match.

Because the 600D active technology is integrated with operation of the lateral tilt system, the adjustments happen automatically; no operator interaction is needed.

For operators considering moving up to larger-width draper platforms, the teaming of HydraFloat and a lateral tilting feederhouse becomes more advantageous for the wider-width platforms cutting over uneven and rolling ground terrain.

Perma-Glide™ divider points and end shields lift and separate standing or down crop

Crop divider

Crop divider

The divider profile of the 600D Draper is designed to lift and separate standing or down crop. This improved profile greatly minimizes outer divider plugging even in down, damp conditions.

Cutterbar full-width skid shoes protect bottom of platform

Poly (yellow) skid shoes

Poly (yellow) skid shoes

Takes only one person a few minutes to convert draper from field to transport without use of tools

The 630D, 635D, and the 640D Draper models can be equipped with an integral, slow-speed transport system.

Customer Value:

- Dual-front dolly wheel tires with an extendable tongue and two-gauge wheel tires carry the complete weight of the draper when in transport, eliminating the need for a header trailer

- One person can convert the draper from field to transport mode in a few minutes without the use of tools, expediting road transport

600D integral transport system

600D integral transport system

600D integral transport system pulled by tractor

600D integral transport system pulled by tractor

Theory of Operation:

Step 1-lock left-hand gauge wheels in place

Step 1-lock left-hand gauge wheels in place

Step 2-lock right-hand gauge and transport wheels

Step 2-lock right-hand gauge and transport wheels

Step 3-position transport warning lights

Step 3-position transport warning lights

Step 4-install transport tongue

Step 4-install transport tongue

In field mode, the dual wheels become the left- and right-hand gauge wheels. For transport, the left-hand dual-dolly wheels support one side of the draper frame and the right-hand dual wheels are repositioned to support the right-hand end of the frame.

The transport package includes warning lights, which can be plugged into a seven-way power source for road transport with a 32.2-km/h (20-mph) speed limit for farm equipment transport.

NOTE: The 630D, 635D, and the 640D Drapers are equipped with two 20.5 x 8.0 12-ply equivalent gauge wheel tires as base equipment and four 20.5 x 8.0 12-ply equivalent gauge wheels with the low-speed transport option.

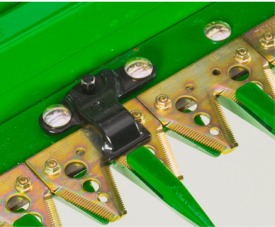

Double-cut knife system produces a cleaner cut

All John Deere 600D Drapers include a double-cut knife which features a hydraulic tilt that is controlled from inside the cab. All 10.6-m (35-ft) and 12.1-m (40-ft) draper cutterbars also have knifeback reinforcement straps to strengthen the knifeback.

Customer Value:

- Longer stroke of knife section provides a faster, cleaner, and smoother cut which allows operators to harvest at faster ground speeds maximizing productivity

- Reinforced knifeback strengthens cutterbar for tough harvesting conditions maximizing performance

- Hardened sickle sections and unique boron treatment extends wear life

- Hydraulic tilt optimizes the cutterbar angle for varying conditions, extending the harvest day and providing the lowest-possible cut height

Double-cut cutterbar system

Double-cut cutterbar system

Double-cut rock guard

Double-cut rock guard

Theory of Operation:

The 100-mm (4-in.) cutting action produces a cleaner cut versus the tearing effect of shorter-stroke cutting systems. Knife hold-downs are easily adjusted to help maintain harvesting performance.

Tilt cylinder

Tilt cylinder

The cutterbar hydraulic tilt adjusts a full 8 degrees while maintaining excellent visibility to the cutterbar throughout the tilt range. For improved ease of use the optional advanced hydro handle can be configured to control the platform tilt.

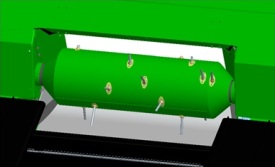

Large, center feed drum improves feeding of crop into combine feederhouse

The center feed drum is designed for efficient, consistent feeding of the crop into the combine feederhouse. A feature for 600D Draper Platforms is a feed drum retractable auger finger to improve crop feeding at the corners of the feed drum.

Customer Value:

- 406-mm (16-in.) diameter feed drum significantly improves feeding of the crop into the combine feederhouse

- Strategic location improves crop handling and capacity, increasing productivity in high-volume crops such as irrigated wheat, barley, or canola

- Retractable fingers enable smoother feeding and better performance of the combine

Center feed drum

Center feed drum

Feed drum retractable auger finger

Feed drum retractable auger finger

Theory of Operation:

The feed drum protrudes forward from the draper back sheets, improving the crop handoff from the draper side belts.

In some crop conditions, crop can hesitate at the corners of the feed drum and the retractable drum fingers keep the crop moving into the combine.

Reel resume and reverse are features on the 600D Drapers

Reel resume and reverse are features on the 600D Drapers. The combine operator can store two different reel positions with one setting for normal conditions and another for down, tangled, short, leaning crops.

Customer Value:

- Added time savings and convenience with saved reel positions, lowering operator fatigue

- Reel-reverse feature reverses the reel in conjunction with the center feed drum and belt to back out plugs and increase harvest efficiency

Draper drum

Draper drum

Draper reel

Draper reel

Two-piece reel design enhances smooth, fast draper feeding in all crop conditions

640D Advanced Draper

640D Advanced Draper

Split-reel design

Split-reel design

The 152-mm (6-in.) diameter reel center tube provides the structural strength needed to support the two-piece reel design on 640D Platforms.

The two-piece reel has a 5-cylinder reel-lift system with tight cutterbar clearance that enhances smooth, fast draper feeding in all crop conditions. The 640D reel system is built for the same high efficiency as previous draper platform reels, allowing the operator to spend less time adjusting and focus more on harvesting.

The two-piece design provides these benefits:

- Superior performance with the split-reel design

- Five-cylinder reel; periodic rephasing may be necessary*

- Excellent visibility due to 152-mm (6-in.) diameter reel center tube

*The 640D will require rephasing when new from the factory as well as after any components are repaired or replaced. If used multiple seasons, it may also be beneficial to rephase at the beginning of a season.

*In normal operation the 5-cylinder reel may lower slowly while running and works best on combines with the closed-center hydraulic system (S680/S690).

Offers and Discounts

Related Products

-

615P Belt Pickup

615P Belt Pickup -

625D Draper Platform

625D Draper Platform -

630D Draper Platform

630D Draper Platform -

630FD Hydraflex™ Draper

630FD Hydraflex™ Draper -

635D Draper Platform

635D Draper Platform -

635FD Hydraflex™ Draper

635FD Hydraflex™ Draper -

640D Draper Platform

640D Draper Platform -

640FD Hydraflex™ Draper

640FD Hydraflex™ Draper -

645FD Hydraflex™ Draper

645FD Hydraflex™ Draper -

725D Draper Platform

725D Draper Platform -

730D Draper Platform

730D Draper Platform -

730FD HydraFlex™ Draper

730FD HydraFlex™ Draper -

735D Draper Platform

735D Draper Platform -

735FD HydraFlex™ Draper

735FD HydraFlex™ Draper -

740D Draper Platform

740D Draper Platform -

740FD HydraFlex™ Draper

740FD HydraFlex™ Draper -

745FD HydraFlex™ Draper

745FD HydraFlex™ Draper

Product features are based on published information at the time of publication. Product features are subject to change without notice. Contact your local John Deere dealer for more information.