Back

- Lawn & Garden

- Agriculture

- Construction

- Landscaping & Grounds Care

- Golf & Sports Turf

- Forestry

- Engines & Drivetrains

- Government & Corporate Sales

- View All Equipment

- View Used Equipment

- Parts

- Manuals & Training

- Warranty & Protection Plans

- Expert Check

- John Deere Connected Support™

- StellarSupport™

- Recalls

- Safety

- Utility Tractors (23-195 Engine HP)

- Specialty Tractors (75-155 Engine HP)

- Row Crop Tractors (145-410 Engine HP)

- 4WD and Track Tractors (390-640 Engine HP)

- Utility Tractors Attachments & Accessories

- Tillage

- Combine Harvesters

- Cotton Harvesters

- Sugar Harvesters

- Hay & Forage

- Planting Equipment

- Seeding Equipment

- Gator™ Utility Vehicles

- Gator™ Attachments & Accessories

- Loaders for Tractors

- Scraper Systems

- Sprayers

- Precision Ag Technology

- Home & Workshop Products

- Used Agriculture Equipment

- INDUSTRIAL DIESEL ENGINES

- Final Tier 4/Stage V

- Interim Tier 4 / Stage III

- Tier 3/Stage III

- Tier 2 and Lesser Regulated

- MARINE ENGINES

- Commercial/Workboat

- Recreational/Pleasure Craft

- GENERATOR DRIVE ENGINES

- Standby/Stationary

- Prime/Portable

- DRIVETRAIN EQUIPMENT

- Pump Drives

- Transmissions

- Axles

- Planetary Gear Drives

- Vehicle Electrification

- TRACTORS & MOWERS

- Ride-On Mowers

- Utility Tractors (22.4-140 Engine HP)

- Specialty Tractors (75-155 Engine HP)

- Residential ZTrak™ Zero-Turn Mowers

- Commercial Mowers

- CONSTRUCTION

- Backhoes

- Compact Track Loaders

- Dozers

- Skid Steers

- Motor Graders

- Wheel Loaders

- UTILITY VEHICLES & ACCESSORIES

- Gator™ Utility Vehicles

- Gator™ Utility Vehicles Attachments & Accessories

- ATTACHMENTS & ACCESSORIES

- Attachments, Accessories & Implements

- Home & Workshop Products

- Front-End Loaders for Tractors

- Application Equipment

- Attachments, Accessories & Implements

- Backhoes

- Dozers

- Engines

- Forwarders

- Gator™ Utility Vehicles

- Hay & Forage

- Combine Harvesters

- Cotton Harvesters

- Sugar Harvesters

- Home & Workshop Products

- Motor Graders

- Mowers

- Planting Equipment

- Precision Ag Technology

- Scraper Systems

- Seeding Equipment

- Skidders

- Sprayers

- Swing Machines

- Tillage

- Tractors

- Home

- 608fc corn head

608FC

Features

Features

Expand All

Collapse All

Feelers signal combine to keep it on the row

Feelers signal combine to keep it on the row

Row sensing is done by the use of feelers

The AutoTrac RowSense increases machine efficiency by:

Row sensing is done by the use of feelers

The AutoTrac RowSense increases machine efficiency by:

StarFire position receiver picks up signal

StarFire position receiver picks up signal

NOTE: AutoTrac RowSense requires a StarFire™ 3000 or StarFire iTC position receiver, GreenStar™ Display, AutoTrac SF1, SF2, or RTK software activation, RowSense software activation, RowSense attachment (for 90 and 600 Series Corn Heads) includes the mechanical sensors, and will operate on S-Series Combines with integrated AutoTrac.

A combine retrofit kit (available through John Deere AMS) may be needed to make combines compatible with AutoTrac RowSense. This attachment includes a wiring harness to make the current AutoTrac system compatible with AutoTrac RowSense.

Due to their increased accuracy, a SF2 or RTK signal is the preferred choice for harvesting applications. For information on StarFire signals and recommendations, see the AMS product information on StarFire iTC Receivers.

NOTE: See the Ag Management Solutions AutoTrac story for the S-Series Combines for additional information.

For specific information regarding RowSense field-installed attachments or kit availability, as well as specific model year STS™ Combine and corn head (90 and 600 Series) compatibility, it is highly recommended to view the John Deere AMS product information.

NOTE: AutoTrac RowSense requires a StarFire™ 3000 or StarFire iTC position receiver, GreenStar™ Display, AutoTrac SF1, SF2, or RTK software activation, RowSense software activation, RowSense attachment (for 90 and 600 Series Corn Heads) includes the mechanical sensors, and will operate on S-Series Combines with integrated AutoTrac.

A combine retrofit kit (available through John Deere AMS) may be needed to make combines compatible with AutoTrac RowSense. This attachment includes a wiring harness to make the current AutoTrac system compatible with AutoTrac RowSense.

Due to their increased accuracy, a SF2 or RTK signal is the preferred choice for harvesting applications. For information on StarFire signals and recommendations, see the AMS product information on StarFire iTC Receivers.

NOTE: See the Ag Management Solutions AutoTrac story for the S-Series Combines for additional information.

For specific information regarding RowSense field-installed attachments or kit availability, as well as specific model year STS™ Combine and corn head (90 and 600 Series) compatibility, it is highly recommended to view the John Deere AMS product information.

600C Row-Unit

600C Row-Unit

The intermeshing knife stalk rolls are the best equipment when the typical harvesting condition is wet corn and using the StalkMaster™ stalk chopping option.

Customer Value:

The intermeshing knife stalk rolls are the best equipment when the typical harvesting condition is wet corn and using the StalkMaster™ stalk chopping option.

Customer Value:

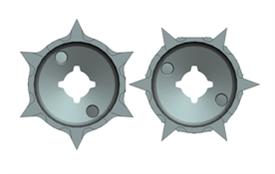

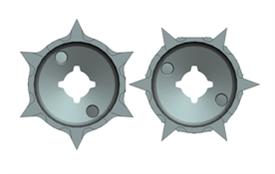

Intermeshing stalk rolls

Intermeshing stalk rolls

Intermeshing knife stalk rolls consist of six full-length blades that contact the crop. The blades cut, crimp, and break the stalks as they are pulled down through the rolls. The full-length blades provide total crop contact for maximum chopping and cutting action from the front to back. Intermeshing knife stalk rolls are also available on StalkMaster™ corn heads. Rolls are constructed of austempered ductile iron material with a dual coating in the front 7.6 cm (3 in.) of high-wear zone for longer life.

The stalk rolls turn at 735 rpm when back shaft speed is at 490 rpm. The tip speed compared to the gathering chain speed is optimized to reduce MOG intake and increase overall capacity while minimizing losses.

The single-piece cast-knife roll design provides excellent serviceability when replacement is required.

Intermeshing knife stalk rolls consist of six full-length blades that contact the crop. The blades cut, crimp, and break the stalks as they are pulled down through the rolls. The full-length blades provide total crop contact for maximum chopping and cutting action from the front to back. Intermeshing knife stalk rolls are also available on StalkMaster™ corn heads. Rolls are constructed of austempered ductile iron material with a dual coating in the front 7.6 cm (3 in.) of high-wear zone for longer life.

The stalk rolls turn at 735 rpm when back shaft speed is at 490 rpm. The tip speed compared to the gathering chain speed is optimized to reduce MOG intake and increase overall capacity while minimizing losses.

The single-piece cast-knife roll design provides excellent serviceability when replacement is required.

608FC Folding Corn Head

608FC Folding Corn Head

Each of the outer two rows of the 608FC fold hydraulically from the cab to allow for narrow transport width during road transport between fields or for storage.

Customer Value:

Each of the outer two rows of the 608FC fold hydraulically from the cab to allow for narrow transport width during road transport between fields or for storage.

Customer Value:

Folding cylinders on 612FC shown

Folding cylinders on 612FC shown

Two large, durable-frame folding cylinders provide smooth hydraulic force to move the corn head wings from the working position or field position to the transport position.

Two large, durable-frame folding cylinders provide smooth hydraulic force to move the corn head wings from the working position or field position to the transport position.

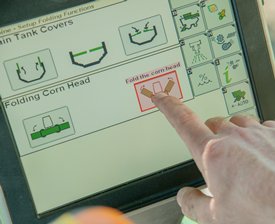

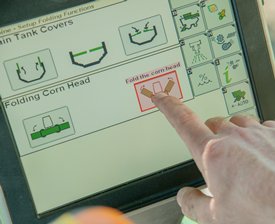

Armrest display

Armrest display

The control of the 608FC folding function is integrated into the operator cab of S-Series Combines. Operators can fold the 608FC quickly and easily from the armrest display screen without leaving the cab.

The control of the 608FC folding function is integrated into the operator cab of S-Series Combines. Operators can fold the 608FC quickly and easily from the armrest display screen without leaving the cab.

600C Row Unit

600C Row Unit

The opposed knife stalk rolls are the best equipment when the typical harvesting condition is dry corn and using the StalkMaster™ stalk chopping option.

Customer Value:

The opposed knife stalk rolls are the best equipment when the typical harvesting condition is dry corn and using the StalkMaster™ stalk chopping option.

Customer Value:

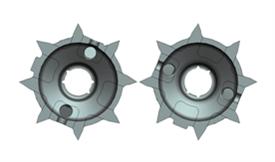

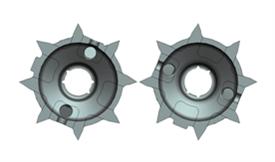

Opposed knife stalk roll

Opposed knife stalk roll

Rolls are designed with eight opposed, full-length blades that result in better stalk control, improved stalk processing, and reduced material-other-than-grain (MOG) intake. This eight-blade design improves function and reduces localized blade wear in the front of the rolls. Rolls are constructed of austempered ductile iron material with a dual coating in the front 7.6 cm (3 in.) of high-wear zone for longer life.

The stalk rolls turn at 1050 rpm when back shaft speed is at 700 rpm. The tip speed compared to the gathering chain speed is optimized to reduce MOG intake and increase overall capacity while minimizing losses.

The single-piece cast knife roll design provides excellent serviceability when replacement is required.

Rolls are designed with eight opposed, full-length blades that result in better stalk control, improved stalk processing, and reduced material-other-than-grain (MOG) intake. This eight-blade design improves function and reduces localized blade wear in the front of the rolls. Rolls are constructed of austempered ductile iron material with a dual coating in the front 7.6 cm (3 in.) of high-wear zone for longer life.

The stalk rolls turn at 1050 rpm when back shaft speed is at 700 rpm. The tip speed compared to the gathering chain speed is optimized to reduce MOG intake and increase overall capacity while minimizing losses.

The single-piece cast knife roll design provides excellent serviceability when replacement is required.

StalkMaster row-unit

StalkMaster row-unit

The StalkMaster Corn Head chopping system allows operator size and chop corn stalks while harvesting, eliminating second-pass operations and saving time. StalkMaster is available on 606C, 608C, 612C, 612FC, 616C, and the 618C Corn Heads.

Customer Value:

The StalkMaster Corn Head chopping system allows operator size and chop corn stalks while harvesting, eliminating second-pass operations and saving time. StalkMaster is available on 606C, 608C, 612C, 612FC, 616C, and the 618C Corn Heads.

Customer Value:

StalkMaster chopping blades

StalkMaster chopping blades

Each of the StalkMaster row-unit gearcase is equipped with two heat-treated and wear-coated rotating blades positioned below the stalk rolls. As stalks are pulled through the rolls stalks are cut to size and distributed evenly throughout the row. If the blades encounter an obstruction they will swing backward avoiding damage and interruption to harvest. Blades can be reversed to extend their useable wear life.

Each of the StalkMaster row-unit gearcase is equipped with two heat-treated and wear-coated rotating blades positioned below the stalk rolls. As stalks are pulled through the rolls stalks are cut to size and distributed evenly throughout the row. If the blades encounter an obstruction they will swing backward avoiding damage and interruption to harvest. Blades can be reversed to extend their useable wear life.

StalkMaster chopping disconnect feature

The gearcase on the StalkMaster row-units feature a no tools needed disconnect. Each row has a convenient shifting lever on the right side of the gearcase to turn the function on or off in a matter of minutes.

StalkMaster chopping disconnect feature

The gearcase on the StalkMaster row-units feature a no tools needed disconnect. Each row has a convenient shifting lever on the right side of the gearcase to turn the function on or off in a matter of minutes.

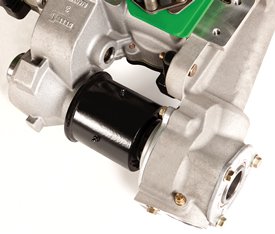

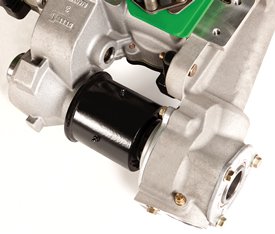

StalkMaster gearcase

StalkMaster gearcase

A heavy-duty slip-clutch design protects both the row-unit gearcase and the StalkMaster lower chopping unit gearcase. If the clutch slips, the operator will know immediately.

A heavy-duty slip-clutch design protects both the row-unit gearcase and the StalkMaster lower chopping unit gearcase. If the clutch slips, the operator will know immediately.

Rubberized curtains

Rubberized curtains

Steel-protective shield

StalkMaster chopping heads feature side- and rear-mounted rubberized curtains to optimize chopped crop residue distribution. Also, the right-hand side of the head has an additional shield for protection from protruding blades.

Steel-protective shield

StalkMaster chopping heads feature side- and rear-mounted rubberized curtains to optimize chopped crop residue distribution. Also, the right-hand side of the head has an additional shield for protection from protruding blades.

612C right-hand side and drive shaft

612C right-hand side and drive shaft

Enclosed chain cases drive the gathering chains and stalk rolls for each row to provide robust durability and uninterrupted harvesting. Heavy-duty bearings mounted in machined castings along with O-ring seals increase life and improve serviceability.

Enclosed chain cases drive the gathering chains and stalk rolls for each row to provide robust durability and uninterrupted harvesting. Heavy-duty bearings mounted in machined castings along with O-ring seals increase life and improve serviceability.

Larger sprockets and chain

Larger sprockets and chain

Continuous-loop American National Standards Institute (ANSI) #100 chain allows for higher loads and longer life by eliminating all connector links and half links. The large-diameter sprockets along with large 38-mm (1.50-in.) transverse hex back shaft and row-unit shafts provide for improved sprocket and chain life.

Continuous-loop American National Standards Institute (ANSI) #100 chain allows for higher loads and longer life by eliminating all connector links and half links. The large-diameter sprockets along with large 38-mm (1.50-in.) transverse hex back shaft and row-unit shafts provide for improved sprocket and chain life.

Telescoping drive shaft

Telescoping drive shaft

Telescoping drive shafts mount to the splined feederhouse back shafts on all 50, 60, 70, W-, T-, C-, and S-Series Combines.

The coupler features an 8-degree index, allowing the operator to match the drive shaft splines without rotating the platform feederhouse.

Telescoping drive shafts:

Telescoping drive shafts mount to the splined feederhouse back shafts on all 50, 60, 70, W-, T-, C-, and S-Series Combines.

The coupler features an 8-degree index, allowing the operator to match the drive shaft splines without rotating the platform feederhouse.

Telescoping drive shafts:

Hydraulic deck plates

Hydraulic deck plates

Hydraulically adjustable deck plates allow the operator to adjust the deck plate opening on the go in order to match changes in stalk or cob size and crop conditions.

Customer Value:

Hydraulically adjustable deck plates allow the operator to adjust the deck plate opening on the go in order to match changes in stalk or cob size and crop conditions.

Customer Value:

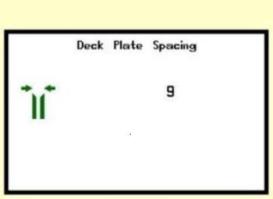

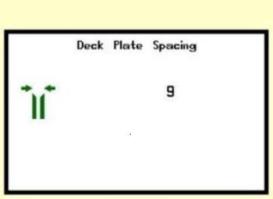

Deck plate spacing

Deck plate spacing

The deck plate spacing indicator is displayed on the corner post display and on the CammandTouch™ display unit on the armrest.

Deck plate resume is also featured with hydraulically adjustable deck plates. Three deck plate positions can be programmed for varying crop conditions using the resume feature.

The deck plate spacing indicator is displayed on the corner post display and on the CammandTouch™ display unit on the armrest.

Deck plate resume is also featured with hydraulically adjustable deck plates. Three deck plate positions can be programmed for varying crop conditions using the resume feature.

AutoTrac™ RowSense™ increases machine efficiency while harvesting corn

Harvesting corn with RowSense

AutoTrac RowSense is a solution for corn growers that increases machine efficiency and reduces operator fatigue. AutoTrac RowSense offers operators the same high levels of convenience and productivity experienced in other crops or with AutoTrac-equipped tractors and self-propelled sprayers. Feelers signal combine to keep it on the row

Feelers signal combine to keep it on the row Row sensing is done by the use of feelers

Row sensing is done by the use of feelers-

Maintaining efficiency through changing crop conditions

-

Reduce grain loss

-

Improve acre-per-hour combine performance

-

Enhanced comfort during long harvest hours

-

Easier operation in reduced-visibility (dusty) conditions

-

Reduced operator stress in down corn situations

StarFire position receiver picks up signal

StarFire position receiver picks up signal

Intermeshing stalk roll options for premium stalk processing

600C Row-Unit

600C Row-Unit

- Majority of stalk material will be sized at 15.2 cm (6 in.) or longer to provide soil protection from wind and water.

- Designed to harvest with low power consumption for high performance and low fuel consumption.

Theory of Operation:

Intermeshing stalk rolls

Intermeshing stalk rolls

Folding capability speeds transport between fields

608FC Folding Corn Head

608FC Folding Corn Head

- Eliminates the need for header transport trailer, reducing the cost of total harvesting equipment.

- Reduces nonproductive harvesting time used to mount header to a transport trailer and reattach it to the combine at the next field.

Theory of Operation:

Folding cylinders on 612FC shown

Folding cylinders on 612FC shown

Armrest display

Armrest display

Opposed stalk roll options for premium stalk processing

600C Row Unit

600C Row Unit

- Majority of stalk material will be sized at 12 inches or longer to provide soil protection from wind and water.

- Designed to harvest with low power consumption for high performance and low fuel consumption.

Theory of Operation:

Opposed knife stalk roll

Opposed knife stalk roll

StalkMaster™ row-unit enables stalk chopping

StalkMaster row-unit

StalkMaster row-unit

- Uniform sizing of corn stalks to speed decomposition and also providing for soil protection from wind and water.

- Eliminates the need for the second-pass operation to size stalk residue, saving time and expense.

- Can be equipped with either intermeshing or apposed knife stalk rolls to match the agronomic needs of individual growers.

- Features a quick, no tools, disconnect feature that provides producers the flexibility to chop, or not, when desired.

Theory of Operation:

StalkMaster chopping blades

StalkMaster chopping blades

StalkMaster chopping disconnect feature

StalkMaster chopping disconnect feature StalkMaster gearcase

StalkMaster gearcase

Rubberized curtains

Rubberized curtains Steel-protective shield

Steel-protective shield 612C right-hand side and drive shaft

612C right-hand side and drive shaft

Larger sprockets and chain

Larger sprockets and chain

Telescoping drive shaft

Telescoping drive shaft

- Feature fast, no-tools coupler

- Can be retrofitted to earlier 90 Series and 40 Series Corn Heads

Hydraulically adjustable deck plates

Hydraulic deck plates

Hydraulic deck plates

- Minimize material-other-than-grain (MOG) intake providing improved separator performance.

- Reduce ear loss to maximize potential yield.

- Minimize premature shelling and kennel damage proving sample quality.

Deck plate spacing

Deck plate spacing

Offers and Discounts

Related Products

Product Information & Support

You May Also Be Interested In

Product features are based on published information at the time of publication. Product features are subject to change without notice. Contact your local John Deere dealer for more information.