Back

- Lawn & Garden

- Agriculture

- Construction

- Landscaping & Grounds Care

- Golf & Sports Turf

- Forestry

- Engines & Drivetrains

- Government & Corporate Sales

- View All Equipment

- View Used Equipment

- Parts

- Manuals & Training

- Warranty & Protection Plans

- Expert Check

- John Deere Connected Support™

- StellarSupport™

- Recalls

- Safety

- Utility Tractors (23-195 Engine HP)

- Specialty Tractors (75-155 Engine HP)

- Row Crop Tractors (145-410 Engine HP)

- 4WD and Track Tractors (390-640 Engine HP)

- Utility Tractors Attachments & Accessories

- Tillage

- Combine Harvesters

- Cotton Harvesters

- Sugar Harvesters

- Hay & Forage

- Planting Equipment

- Seeding Equipment

- Gator™ Utility Vehicles

- Gator™ Attachments & Accessories

- Loaders for Tractors

- Scraper Systems

- Sprayers

- Precision Ag Technology

- Home & Workshop Products

- Used Agriculture Equipment

- INDUSTRIAL DIESEL ENGINES

- Final Tier 4/Stage V

- Interim Tier 4 / Stage III

- Tier 3/Stage III

- Tier 2 and Lesser Regulated

- MARINE ENGINES

- Commercial/Workboat

- Recreational/Pleasure Craft

- GENERATOR DRIVE ENGINES

- Standby/Stationary

- Prime/Portable

- DRIVETRAIN EQUIPMENT

- Pump Drives

- Transmissions

- Axles

- Planetary Gear Drives

- Vehicle Electrification

- TRACTORS & MOWERS

- Ride-On Mowers

- Utility Tractors (22.4-140 Engine HP)

- Specialty Tractors (75-155 Engine HP)

- Residential ZTrak™ Zero-Turn Mowers

- Commercial Mowers

- CONSTRUCTION

- Backhoes

- Compact Track Loaders

- Dozers

- Skid Steers

- Motor Graders

- Wheel Loaders

- UTILITY VEHICLES & ACCESSORIES

- Gator™ Utility Vehicles

- Gator™ Utility Vehicles Attachments & Accessories

- ATTACHMENTS & ACCESSORIES

- Attachments, Accessories & Implements

- Home & Workshop Products

- Front-End Loaders for Tractors

- Application Equipment

- Attachments, Accessories & Implements

- Backhoes

- Dozers

- Engines

- Forwarders

- Gator™ Utility Vehicles

- Hay & Forage

- Combine Harvesters

- Cotton Harvesters

- Sugar Harvesters

- Home & Workshop Products

- Motor Graders

- Mowers

- Planting Equipment

- Precision Ag Technology

- Scraper Systems

- Seeding Equipment

- Skidders

- Sprayers

- Swing Machines

- Tillage

- Tractors

- Home

- ch570 track sugar cane harvester

CH570Track Cane Harvester

- Efficient front end for smooth uniform feed, reducing cane losses and soil content

- Large, premium cab integrates the latest technology with unparalleled comfort

- John Deere-exclusive floating crop divider and contour basecutter height-control technology reduces soil content and cane loss

- Harvest monitor will monitor harvester activities to improve operations

Features

Features

Expand All

Collapse All

Exclusive John Deere technology

Exclusive John Deere technology

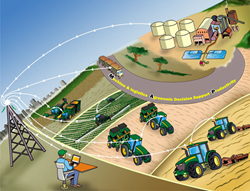

Data-driven decisions

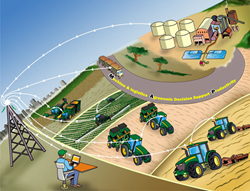

Harvest Monitor is an industry-exclusive technology from John Deere. Harvest Monitor gathers and analyzes valuable harvest information, enabling sugarcane producers to make smarter decisions that drive down harvesting costs and improve overall farming practices.

From the cab, the operator can monitor total tons harvested, harvester productivity, trash percentage, and fuel consumption. The operator can then use this information to make on-the-fly adjustments to optimize performance.

SmartClean is the latest enhancement of Harvest Monitor that allows automatic control of primary extractor fan speed based on the operator’s preferences in order to obtain the most profitable balance between cane cleanliness and reduced loss.

Through the John Deere Operations Center, the data can be processed to generate yield and other valuable maps and reports that will guide producers into making the right decisions on soil and water management, chemical application, crop renewal, field layout, equipment logistics, and much more.

Harvest Monitor with SmartClean is available as an option for model year 2021 CH570 and CH670 Sugar Cane Harvesters as part of Cane Advisor™ machine optimization technology package (code 2904). It can also be purchased as a field-installed kit for all CH570 and CH670 models. A separate SmartClean field-installed kit is available for CH570 and CH670 models already equipped with Harvest Monitor.

Data-driven decisions

Harvest Monitor is an industry-exclusive technology from John Deere. Harvest Monitor gathers and analyzes valuable harvest information, enabling sugarcane producers to make smarter decisions that drive down harvesting costs and improve overall farming practices.

From the cab, the operator can monitor total tons harvested, harvester productivity, trash percentage, and fuel consumption. The operator can then use this information to make on-the-fly adjustments to optimize performance.

SmartClean is the latest enhancement of Harvest Monitor that allows automatic control of primary extractor fan speed based on the operator’s preferences in order to obtain the most profitable balance between cane cleanliness and reduced loss.

Through the John Deere Operations Center, the data can be processed to generate yield and other valuable maps and reports that will guide producers into making the right decisions on soil and water management, chemical application, crop renewal, field layout, equipment logistics, and much more.

Harvest Monitor with SmartClean is available as an option for model year 2021 CH570 and CH670 Sugar Cane Harvesters as part of Cane Advisor™ machine optimization technology package (code 2904). It can also be purchased as a field-installed kit for all CH570 and CH670 models. A separate SmartClean field-installed kit is available for CH570 and CH670 models already equipped with Harvest Monitor.

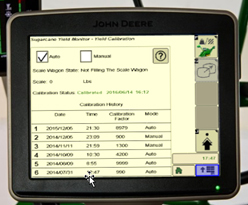

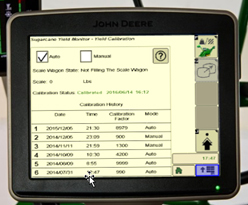

Harvest Monitor installed on a CH570

Harvest Monitor installed on a CH570

Harvest Monitor is much more than just a yield monitor. It includes:

Harvest Monitor is much more than just a yield monitor. It includes:

Harvest Monitor

Harvest Monitor

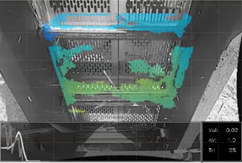

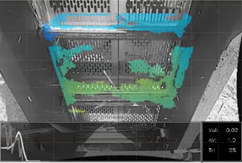

High-resolution optical sensors

High-resolution, stereoscopic optical sensors and pattern recognition technology are used to scan the flow of cane as it passes through the elevator, identifying cane volume and differentiating it from trash. Four light-emitting diode (LED) lights illuminate the sampling area to ensure uninterrupted visual clarity.

High-resolution optical sensors

High-resolution, stereoscopic optical sensors and pattern recognition technology are used to scan the flow of cane as it passes through the elevator, identifying cane volume and differentiating it from trash. Four light-emitting diode (LED) lights illuminate the sampling area to ensure uninterrupted visual clarity.

Flow of cane being scanned

Flow of cane being scanned

Image recognition

The system converts the volumes to mass in order to obtain tons of cane and extraneous matter level.

Image recognition

The system converts the volumes to mass in order to obtain tons of cane and extraneous matter level.

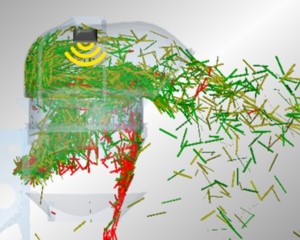

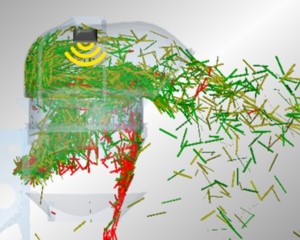

SmartClean illustration

With the use of sensors, the SmartClean system detects cane being lost through the primary extractor and displays it on the CommandCenter screen as an index. The level of residue or cane leaves being removed is also detected and displayed as an index.

Aiming at the best economic outcome for the operation, the operator selects the target level of the following parameters and lets the system continuously and automatically find the appropriate primary extractor fan speed:

SmartClean illustration

With the use of sensors, the SmartClean system detects cane being lost through the primary extractor and displays it on the CommandCenter screen as an index. The level of residue or cane leaves being removed is also detected and displayed as an index.

Aiming at the best economic outcome for the operation, the operator selects the target level of the following parameters and lets the system continuously and automatically find the appropriate primary extractor fan speed:

StarFire™ 6000 Receiver

StarFire™ 6000 Receiver

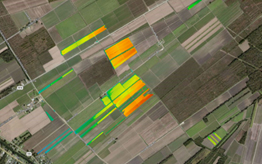

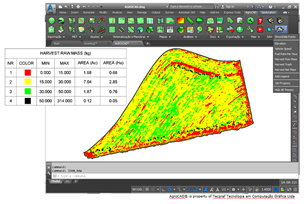

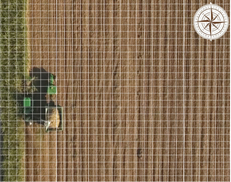

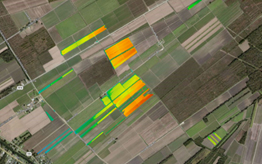

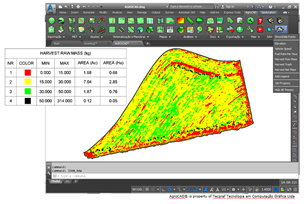

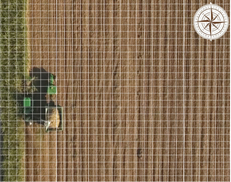

Sugar cane field yield map

Data points are georeferenced to precise field locations using global positioning system (GPS) technology. With appropriate software, a variety of informative maps can be generated. The system operation requires a GPS receiver (StarFire 6000 Receiver is recommended).

Sugar cane field yield map

Data points are georeferenced to precise field locations using global positioning system (GPS) technology. With appropriate software, a variety of informative maps can be generated. The system operation requires a GPS receiver (StarFire 6000 Receiver is recommended).

Harvest Monitor screen

Harvest Monitor screen

On-screen live cane flow

On-screen live cane flow

SmartClean shown on the CommandCenter

SmartClean shown on the CommandCenter

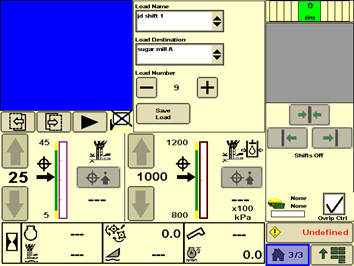

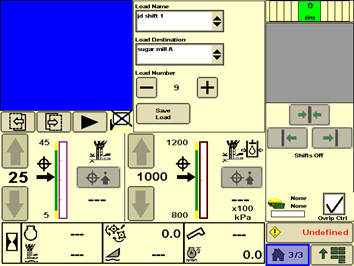

Screen shot showing load counter

Screen shot showing load counter

To keep records of the number of wagons completed, the operator will click the “Save Load” soft key every time a unit is loaded. The screen will show the total loads from a field, shift, whole season, or another preselected period of time. The sugar mill destination can also be recorded for each load.

To keep records of the number of wagons completed, the operator will click the “Save Load” soft key every time a unit is loaded. The screen will show the total loads from a field, shift, whole season, or another preselected period of time. The sugar mill destination can also be recorded for each load.

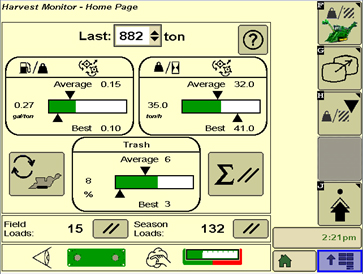

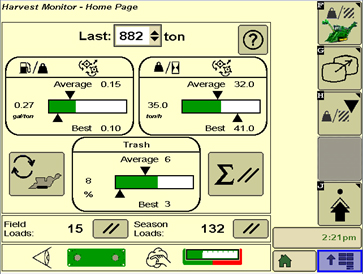

Harvest Monitor screen shot

Harvest Monitor screen shot

While harvesting, the display will show:

While harvesting, the display will show:

CH570 operating in the field

CH570 operating in the field

With SmartClean activated and based on live information, the operator can make other quick adjustments to the harvester, like ground speed and FieldCruise™ settings, to maintain the most profitable harvesting rate while delivering the preferred level of cane quality and reduced loss.

With SmartClean activated and based on live information, the operator can make other quick adjustments to the harvester, like ground speed and FieldCruise™ settings, to maintain the most profitable harvesting rate while delivering the preferred level of cane quality and reduced loss.

Primary extractor fan blades

Primary extractor fan blades

Chopper blades

The system will also help to determine when the chopper and extractor fan blades need to be replaced, or if other related service is required in order to maintain optimum operating performance.

Chopper blades

The system will also help to determine when the chopper and extractor fan blades need to be replaced, or if other related service is required in order to maintain optimum operating performance.

In-field equipment transloading into highway trucks

In-field equipment transloading into highway trucks

Multiple harvesters

The live yield data simplifies daily logistics decisions, including the number of transport units required and the correct timing to efficiently complete the assigned cane quota. In addition, field harvesting progress and remaining unharvested area can be seen on the screen for a great visual of the operation that can facilitate the transition to the next field.

Multiple harvesters

The live yield data simplifies daily logistics decisions, including the number of transport units required and the correct timing to efficiently complete the assigned cane quota. In addition, field harvesting progress and remaining unharvested area can be seen on the screen for a great visual of the operation that can facilitate the transition to the next field.

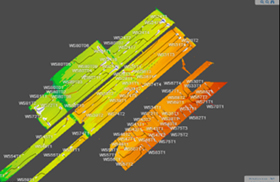

Total mass map (cane and trash)

Total mass map (cane and trash)

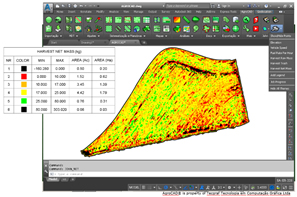

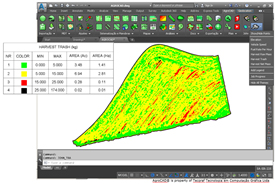

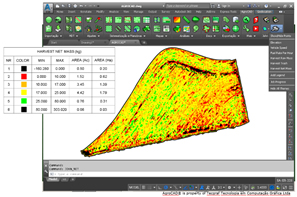

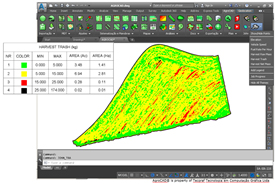

Cane map

Cane map

Surveying the field while harvesting

Surveying the field while harvesting

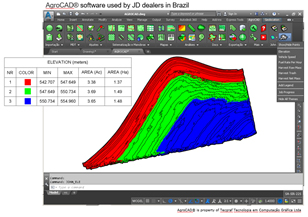

Map showing low and high areas

Georeferenced samples that include elevation readings are taken every second. As the harvester travels down each row, numerous elevation readings representing the topography of the area harvested are recorded.

Example of a typical field:

Map showing low and high areas

Georeferenced samples that include elevation readings are taken every second. As the harvester travels down each row, numerous elevation readings representing the topography of the area harvested are recorded.

Example of a typical field:

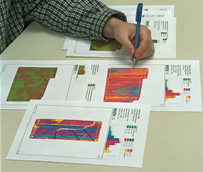

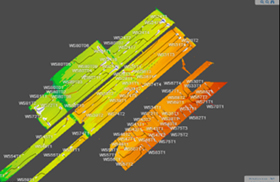

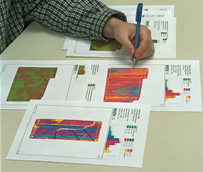

Generated maps

Generated maps

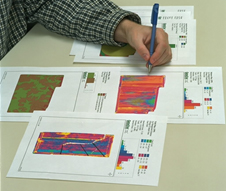

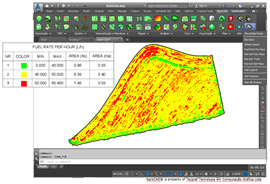

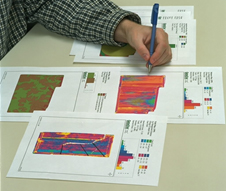

Decisions on agronomical practices and logistics

The Harvest Monitor data can be processed through John Deere’s Operations Center to generate maps and reports that will help optimize operations.

Different types of maps can be created for a clear visualization of current farm conditions:

Decisions on agronomical practices and logistics

The Harvest Monitor data can be processed through John Deere’s Operations Center to generate maps and reports that will help optimize operations.

Different types of maps can be created for a clear visualization of current farm conditions:

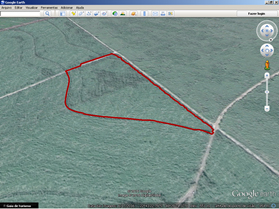

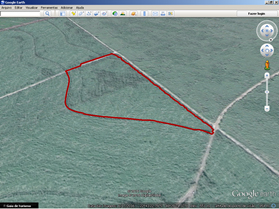

Location map using Google Earth™ mapping service

Location map using Google Earth™ mapping service

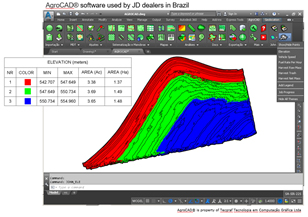

Elevation map

Elevation map

Extraneous matter (trash) map

Extraneous matter (trash) map

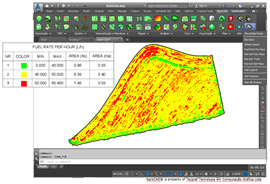

Fuel-rate map

The maps and reports will help to determine the best solutions for:

Fuel-rate map

The maps and reports will help to determine the best solutions for:

CH570 working with weigh wagon

CH570 working with weigh wagon

Calibration screen

During harvesting, the Harvest Monitor can be calibrated manually by entering weight information for the load supplied by the mill.

The maps can also be calibrated using field report data supplied from the sugar mill.

Google Earth is a trademark of Google LLC.

Calibration screen

During harvesting, the Harvest Monitor can be calibrated manually by entering weight information for the load supplied by the mill.

The maps can also be calibrated using field report data supplied from the sugar mill.

Google Earth is a trademark of Google LLC.

CH570 cab interior

CH570 cab interior

The premium smart cab is 30 percent more spacious and offers all the necessary comfort, convenience, and intelligent features operators will ever need.

Reduced noise levels (76 dB) plus improved air conditioning cooling with overhead vents will keep the operator relaxed during long working hours.

The premium smart cab is 30 percent more spacious and offers all the necessary comfort, convenience, and intelligent features operators will ever need.

Reduced noise levels (76 dB) plus improved air conditioning cooling with overhead vents will keep the operator relaxed during long working hours.

CH570 cab exterior

CH570 cab exterior

Operators can access the cab conveniently from the right or from the left.

The wide windshield is curved for enhanced visibility and strength. The left- and right-hand folding arms, adjustable rearview mirrors, and the in-cab convex mirror facilitates viewing the elevator and wagon.

The cab comes standard with windshield and side glass wipers with washer fluid nozzles.

Eight lights are used on the cab, including four high-luminosity lights that greatly facilitate night operation.

Operators can access the cab conveniently from the right or from the left.

The wide windshield is curved for enhanced visibility and strength. The left- and right-hand folding arms, adjustable rearview mirrors, and the in-cab convex mirror facilitates viewing the elevator and wagon.

The cab comes standard with windshield and side glass wipers with washer fluid nozzles.

Eight lights are used on the cab, including four high-luminosity lights that greatly facilitate night operation.

Air suspension seat

The air suspension seat has multiple adjustments and swivels so operators can find the perfect fit and viewing angle.

Training is made safer and easier with a training seat standard in every CH570.

Air suspension seat

The air suspension seat has multiple adjustments and swivels so operators can find the perfect fit and viewing angle.

Training is made safer and easier with a training seat standard in every CH570.

Double-tilt telescopic steering column

Adjust the double-tilt telescopic steering column to driving preferences. Road controls are located on the steering column.

Double-tilt telescopic steering column

Adjust the double-tilt telescopic steering column to driving preferences. Road controls are located on the steering column.

Integrated refrigerator

The refrigerator, 37 L (1.3 cu ft) in size, keeps beverages and food items cold, even in a warm environment. The compressor-style refrigerator functions with independent temperature control and is powered from a 12-V receptacle in the rear cab wall that is powered when the ignition switch is in the run position.

Access to the refrigerator is easy because the instructor seat can either be lifted, exposing the contents in the active refrigerator, or the front door of the refrigerator can be opened, also providing access to the contents.

NOTE: The refrigerator is not available for all markets.

Integrated refrigerator

The refrigerator, 37 L (1.3 cu ft) in size, keeps beverages and food items cold, even in a warm environment. The compressor-style refrigerator functions with independent temperature control and is powered from a 12-V receptacle in the rear cab wall that is powered when the ignition switch is in the run position.

Access to the refrigerator is easy because the instructor seat can either be lifted, exposing the contents in the active refrigerator, or the front door of the refrigerator can be opened, also providing access to the contents.

NOTE: The refrigerator is not available for all markets.

Auxiliary LED light on elevator

Auxiliary LED light on elevator

Auxiliary LED light on cooling package

Standard auxiliary lights are halogen type, located on the elevator (two) and the cooling package (two). For optimum brightness on the wagon, add the optional LED auxiliary light kit.

Auxiliary LED light on cooling package

Standard auxiliary lights are halogen type, located on the elevator (two) and the cooling package (two). For optimum brightness on the wagon, add the optional LED auxiliary light kit.

Optional topper boom light

Optional topper boom light

The optional auxiliary light kit includes a topper boom light to service base cutter and front-end components.

The optional auxiliary light kit includes a topper boom light to service base cutter and front-end components.

CommandARM™ control panel

CommandARM™ control panel

User-friendly, and quick to locate, the CommandARM control center is home to every operating feature needed for a simple yet productive day. That includes hot keys for all common harvesting adjustments as well as air conditioning, radio (if equipped), and lighting controls. Navigate through the CommandCenter™ system screens using the navigation control knob located on the CommandARM.

User-friendly, and quick to locate, the CommandARM control center is home to every operating feature needed for a simple yet productive day. That includes hot keys for all common harvesting adjustments as well as air conditioning, radio (if equipped), and lighting controls. Navigate through the CommandCenter™ system screens using the navigation control knob located on the CommandARM.

Digital cornerpost display

Digital cornerpost display

The color, digital cornerpost display graphically illustrates everything an operator needs to know about engine and harvesting parameters. It is located in the optimal line-of-sight to minimize operator disruption.

The color, digital cornerpost display graphically illustrates everything an operator needs to know about engine and harvesting parameters. It is located in the optimal line-of-sight to minimize operator disruption.

GreenStar™ 3 2630 Display

The 25.4-cm (10-in.) GreenStar 3 2630 Display puts vital machine and harvesting information within easy reach. With touchscreen technology, it is simple to make quick adjustments. It provides 70 degrees of swivel for transport or viewing preference. Also, the banner bar has been improved with engine on/off key. A banner bar will show hours for harvester, engine, elevator, AutoTrac™ assisted steering system, floating crop dividers, and contour base cutter height control. Once the engine is started, it shows engine and harvesting functions. Icons turn green when active.

It is video capable, and it can run AutoTrac.

To maintain quality and uniformity of the operation, save fuel and protect assets, supervisors can lock important settings such as:

GreenStar™ 3 2630 Display

The 25.4-cm (10-in.) GreenStar 3 2630 Display puts vital machine and harvesting information within easy reach. With touchscreen technology, it is simple to make quick adjustments. It provides 70 degrees of swivel for transport or viewing preference. Also, the banner bar has been improved with engine on/off key. A banner bar will show hours for harvester, engine, elevator, AutoTrac™ assisted steering system, floating crop dividers, and contour base cutter height control. Once the engine is started, it shows engine and harvesting functions. Icons turn green when active.

It is video capable, and it can run AutoTrac.

To maintain quality and uniformity of the operation, save fuel and protect assets, supervisors can lock important settings such as:

Multifunction control lever

The multifunction control lever fits the operator’s hand comfortably to give smooth, hydrostatic speed control. It also controls all frequently used harvesting functions.

Three programmable buttons are included to customize harvester functions to operator preferences.

No longer on the floor, the elevator swing is easily controlled from the multifunction control lever. One extra click and the elevator will swing 90 degrees.

Multifunction control lever

The multifunction control lever fits the operator’s hand comfortably to give smooth, hydrostatic speed control. It also controls all frequently used harvesting functions.

Three programmable buttons are included to customize harvester functions to operator preferences.

No longer on the floor, the elevator swing is easily controlled from the multifunction control lever. One extra click and the elevator will swing 90 degrees.

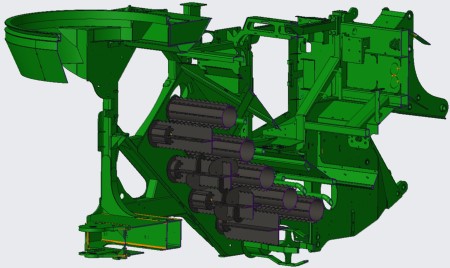

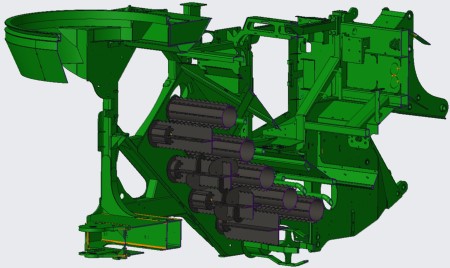

Piston motor-driven basecutter

Piston motor-driven basecutter

Piston motor-driven chopper

The CH570’s basecutter and chopper set the benchmark for cutting and feeding in the global market. The standard 251-kW (337-hp) engine option has the basecutter and chopper on one high-pressure hydrostatic circuit driven by a powerful piston pump maximizing efficiency. The 280-kW (375-hp) option includes an additional piston pump so that the basecutter and chopper are in two independent circuits, increasing the capacity to process the heaviest cane.

Piston motor-driven chopper

The CH570’s basecutter and chopper set the benchmark for cutting and feeding in the global market. The standard 251-kW (337-hp) engine option has the basecutter and chopper on one high-pressure hydrostatic circuit driven by a powerful piston pump maximizing efficiency. The 280-kW (375-hp) option includes an additional piston pump so that the basecutter and chopper are in two independent circuits, increasing the capacity to process the heaviest cane.

Hard-surfaced closed buttlifter

The basecutter is driven by a powerful hydraulic piston motor. Its center-driven design with just four gears, balances the load and reduces wear, and is housed in a more robust cast-iron gearbox.

The basecutter features large, standard 61-cm (24-in.) disks that can be upgraded to 55.9-cm (22-in.) steel disks to allow dirt to flow through in muddier conditions.

Contour basecutter height control is a factory option that adjusts the basecutter height to achieve a predetermined cane stubble height.

Once cut, the CH570’s rotating, standard three-paddle closed buttlifter kicks the cane stalks up into the feedroller path and removes excess dirt before it enters.

Hard-surfaced closed buttlifter

The basecutter is driven by a powerful hydraulic piston motor. Its center-driven design with just four gears, balances the load and reduces wear, and is housed in a more robust cast-iron gearbox.

The basecutter features large, standard 61-cm (24-in.) disks that can be upgraded to 55.9-cm (22-in.) steel disks to allow dirt to flow through in muddier conditions.

Contour basecutter height control is a factory option that adjusts the basecutter height to achieve a predetermined cane stubble height.

Once cut, the CH570’s rotating, standard three-paddle closed buttlifter kicks the cane stalks up into the feedroller path and removes excess dirt before it enters.

Optional four-bar open buttlifter

This option will allow more dirt removal than the current three-paddle closed option.

Optional four-bar open buttlifter

This option will allow more dirt removal than the current three-paddle closed option.

Chopper with exclusive sill roller

A powerful, hydraulic-piston motor drives the 380-mm (15-in.) differential chopper fitted with either six, eight, or 10 95-mm (3.75-in.) blades. The externally mounted bearings are simple to replace. The chopper shafts have no splines to wear, and they can easily slide out from the side for service. The chopper cover is International Organization for Standardization (ISO) compliant.

Eight-blade and 10-blade overlap choppers are also available, increasing the life of the blades in most conditions and simplifying removal and replacement.

The blades are 910-mm (35.8-in.) long or 6.3 cm (2.5 in.) longer than previous model.

Approximate billet length:

Chopper with exclusive sill roller

A powerful, hydraulic-piston motor drives the 380-mm (15-in.) differential chopper fitted with either six, eight, or 10 95-mm (3.75-in.) blades. The externally mounted bearings are simple to replace. The chopper shafts have no splines to wear, and they can easily slide out from the side for service. The chopper cover is International Organization for Standardization (ISO) compliant.

Eight-blade and 10-blade overlap choppers are also available, increasing the life of the blades in most conditions and simplifying removal and replacement.

The blades are 910-mm (35.8-in.) long or 6.3 cm (2.5 in.) longer than previous model.

Approximate billet length:

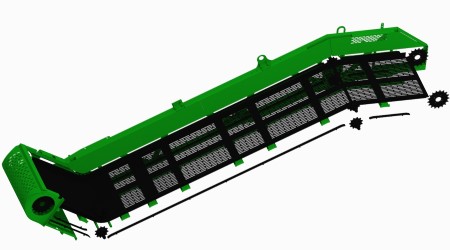

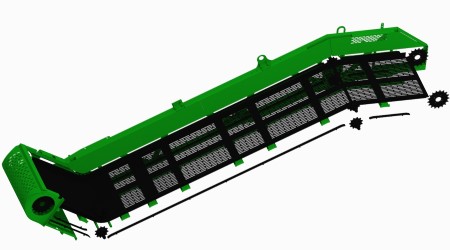

High-capacity elevator

High-capacity elevator

Primary extractor in action

The CH570’s reliable cleaning system yields the cleanest cane in the industry. Cleaner cane, less billet loss, and less downtime will bring more profit.

Primary extractor in action

The CH570’s reliable cleaning system yields the cleanest cane in the industry. Cleaner cane, less billet loss, and less downtime will bring more profit.

The largest primary extractor in the industry

The largest primary extractor in the industry

Wider blades and conical hub

The CH570 boasts the largest primary extractor fan in the industry — using four blades that measure 152 cm (5 ft) in diameter. This fan cleans at lower speeds, reducing horsepower consumption and cane losses.

The fan speed can be adjusted effortlessly from the cab to adapt to the different cane conditions by simply varying the pump displacement. The fan is driven by a robust and efficient hydrostatic system with piston pump and motor.

The fan is mounted directly to the motor shaft, which means no bearings, no blade balancing, less vibration, and fewer components. The motor drive support system features four rubber-mounted legs to improve fan stability and reduce vibrations. The primary extractor fan’s motor is internally mounted and does not need to be removed for transport.

The conical hub cover reduces air voids and recirculation while the wide-design blade produces more airflow at lower rpm. The hard-surfaced blades combined with operating at a much lower speed results in significantly longer blade life.

Wider blades and conical hub

The CH570 boasts the largest primary extractor fan in the industry — using four blades that measure 152 cm (5 ft) in diameter. This fan cleans at lower speeds, reducing horsepower consumption and cane losses.

The fan speed can be adjusted effortlessly from the cab to adapt to the different cane conditions by simply varying the pump displacement. The fan is driven by a robust and efficient hydrostatic system with piston pump and motor.

The fan is mounted directly to the motor shaft, which means no bearings, no blade balancing, less vibration, and fewer components. The motor drive support system features four rubber-mounted legs to improve fan stability and reduce vibrations. The primary extractor fan’s motor is internally mounted and does not need to be removed for transport.

The conical hub cover reduces air voids and recirculation while the wide-design blade produces more airflow at lower rpm. The hard-surfaced blades combined with operating at a much lower speed results in significantly longer blade life.

Smart power primary extractor setting

The smart power primary extractor feature is available to automatically reduce the extractor fan speed to a preset minimum when the elevator is turned off.

Smart power primary extractor setting

The smart power primary extractor feature is available to automatically reduce the extractor fan speed to a preset minimum when the elevator is turned off.

Robust structural tube frame elevator with perforated floor

Robust structural tube frame elevator with perforated floor

Heavy-duty swing table

The CH570 features a high-capacity, structural tube-frame elevator for extended durability. The elevator’s perforated floor allows additional dirt to fall through after primary extraction. The top and bottom idler sprockets reduce wear and prolong the elevator’s chain life.

The tall sidewalls and 18-cm (7-in.) reversible slats will handle the heaviest cane, keeping billets from toppling over and falling back down the elevator. All of this sits on the CH570’s heavy-duty swing table, designed to withstand the heaviest loads and toughest field conditions. The swing table also features an exclusive slew wiper to keep the area clean.

The elevator hoses are routed inside the solid frame, promoting longer life by improving protection and minimizing exposure. Bolt-on elevator extensions are also available to provide additional reach for wider row spacing. The extensions are 30.5 cm (12 in.) for wheel or track units; and 61 cm or 86 cm (24 in. or 34 in.) for track units only. The 61-cm (24-in.) extension can be ordered for wheel harvesters but it requires the less-secondary-extractor option.

On the CH570, the elevator controls were moved from the floor pedals to the multifunction control lever for ease of operation. The control switches feature a double-detent system so that the elevator swings approximate 90 degrees without having to depress the switch continuously. The above will help the operator to concentrate on other functions when turning around on the headland while the elevator is rotating.

Heavy-duty swing table

The CH570 features a high-capacity, structural tube-frame elevator for extended durability. The elevator’s perforated floor allows additional dirt to fall through after primary extraction. The top and bottom idler sprockets reduce wear and prolong the elevator’s chain life.

The tall sidewalls and 18-cm (7-in.) reversible slats will handle the heaviest cane, keeping billets from toppling over and falling back down the elevator. All of this sits on the CH570’s heavy-duty swing table, designed to withstand the heaviest loads and toughest field conditions. The swing table also features an exclusive slew wiper to keep the area clean.

The elevator hoses are routed inside the solid frame, promoting longer life by improving protection and minimizing exposure. Bolt-on elevator extensions are also available to provide additional reach for wider row spacing. The extensions are 30.5 cm (12 in.) for wheel or track units; and 61 cm or 86 cm (24 in. or 34 in.) for track units only. The 61-cm (24-in.) extension can be ordered for wheel harvesters but it requires the less-secondary-extractor option.

On the CH570, the elevator controls were moved from the floor pedals to the multifunction control lever for ease of operation. The control switches feature a double-detent system so that the elevator swings approximate 90 degrees without having to depress the switch continuously. The above will help the operator to concentrate on other functions when turning around on the headland while the elevator is rotating.

Grease cylinder chain tensioning

Grease cylinder chain tensioning

Nitrogen accumulator

The CH570’s elevator also has a grease cylinder for easy elevator chain tension adjustment and a nitrogen accumulator to minimize shock loads.

Nitrogen accumulator

The CH570’s elevator also has a grease cylinder for easy elevator chain tension adjustment and a nitrogen accumulator to minimize shock loads.

Secondary extractor and bin flap

Secondary extractor and bin flap

Optional without secondary extractor

The secondary extractor provides even more cleaning prior to loading. Its unique design allows trash to be blown away from the wagons more efficiently. The hood rotates a full 360 degrees, so it can be set at any angle.

The hydraulically adjustable bin flap directs billets into the wagon. The ideal fan speed allows the best cleaning with low horsepower consumption. For growers who burn cane, a less-secondary-extractor option is available.

Optional without secondary extractor

The secondary extractor provides even more cleaning prior to loading. Its unique design allows trash to be blown away from the wagons more efficiently. The hood rotates a full 360 degrees, so it can be set at any angle.

The hydraulically adjustable bin flap directs billets into the wagon. The ideal fan speed allows the best cleaning with low horsepower consumption. For growers who burn cane, a less-secondary-extractor option is available.

Floating crop dividers and contour basecutter height control

Floating crop dividers and contour basecutter height control

The unique floating crop divider technology was inherited by the CH570 and enhanced with an updated linkage system. The floating crop dividers follow the ground profile without plowing while constantly keeping the toe under lodged cane. The benefits are lower soil content, reduced cane loss, and minimum soil disturbance.

The precision of the exclusive contour basecutter height control is enhanced with the addition of a pressure signal to the existing position input. The system ensures that cane is cut at the desired height, resulting in higher yield (tons of sugar/ha), cleaner cane, and healthier stubble for improved future crops.

Operators can count on these systems to accurately control the basecutter and crop dividers. This allows more time to concentrate on other functions such as topping, following the row, and loading.

Basecutter height control and floating crop dividers are included in the Precision Ag, Machine Optimization Technology option (code 2903).

The unique floating crop divider technology was inherited by the CH570 and enhanced with an updated linkage system. The floating crop dividers follow the ground profile without plowing while constantly keeping the toe under lodged cane. The benefits are lower soil content, reduced cane loss, and minimum soil disturbance.

The precision of the exclusive contour basecutter height control is enhanced with the addition of a pressure signal to the existing position input. The system ensures that cane is cut at the desired height, resulting in higher yield (tons of sugar/ha), cleaner cane, and healthier stubble for improved future crops.

Operators can count on these systems to accurately control the basecutter and crop dividers. This allows more time to concentrate on other functions such as topping, following the row, and loading.

Basecutter height control and floating crop dividers are included in the Precision Ag, Machine Optimization Technology option (code 2903).

Double click to activate end of row and return to cut

Double click to activate end of row and return to cut

To reduce headland turnaround time, end-of-row and return-to-cut technology is also available. The harvester and crop dividers rise simultaneously with a single button when exiting the field and, upon entering the next row, the unit returns to the predefined cutting height setting.

Stress and fatigue are significantly lessened while optimizing harvester performance. The end-of-row and return-to-cut systems make the harvester operation so simple that the learning curve for inexperienced users is diminished considerably.

To reduce headland turnaround time, end-of-row and return-to-cut technology is also available. The harvester and crop dividers rise simultaneously with a single button when exiting the field and, upon entering the next row, the unit returns to the predefined cutting height setting.

Stress and fatigue are significantly lessened while optimizing harvester performance. The end-of-row and return-to-cut systems make the harvester operation so simple that the learning curve for inexperienced users is diminished considerably.

CH570 Harvester reentering the field

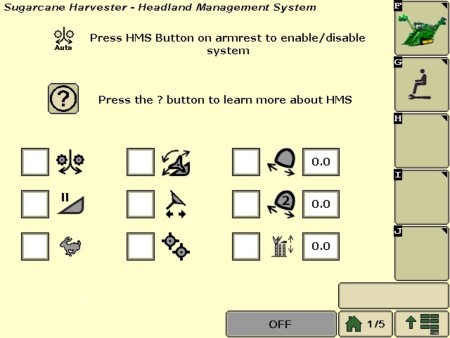

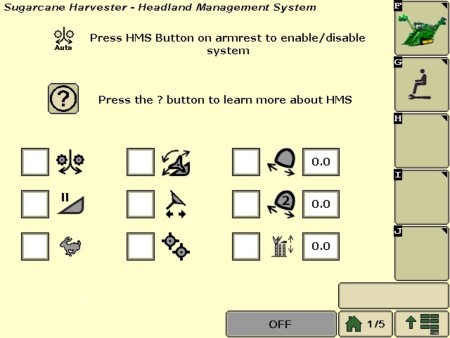

The HMS adds a powerful productivity tool to the CH570 Sugar Cane Harvester. HMS greatly reduces operator fatigue through the automatic sequencing of harvesting functions normally associated with headland turns.

CH570 Harvester reentering the field

The HMS adds a powerful productivity tool to the CH570 Sugar Cane Harvester. HMS greatly reduces operator fatigue through the automatic sequencing of harvesting functions normally associated with headland turns.

Operator activates HMS with one button

HMS can be programmed to control some of or all the following harvesting functions:

Operator activates HMS with one button

HMS can be programmed to control some of or all the following harvesting functions:

Multifunction control lever

Producers can opt for contour basecutter height control and floating crop dividers to maximize HMS capabilities.

Multifunction control lever

Producers can opt for contour basecutter height control and floating crop dividers to maximize HMS capabilities.

HMS screen on the display

The system includes a prediction algorithm to update the cutting side, reducing the need to press swap buttons.

HMS screen on the display

The system includes a prediction algorithm to update the cutting side, reducing the need to press swap buttons.

Illustration of CH570 elevator with XWear parts in black

Illustration of CH570 elevator with XWear parts in black

Illustration of feedroller train with XWear parts in black

The CH570 and CH670 Sugar Cane Harvester extended life elevator and feedroller system option includes John Deere XWear prolonged-life components. XWear parts combine abrasion-resistant materials with the latest treatment technologies to deliver the longest life at a lower maintenance cost. XWear parts are ideal for extreme operating conditions or for simply getting through long harvest seasons without excessive downtime. The option includes highly abrasion-resistant elevator floor segments and chain wear strips, additional hard-surfaced feedrollers, extreme-duty tapered roller bearings, and hardened elevator chain sprockets.

Illustration of feedroller train with XWear parts in black

The CH570 and CH670 Sugar Cane Harvester extended life elevator and feedroller system option includes John Deere XWear prolonged-life components. XWear parts combine abrasion-resistant materials with the latest treatment technologies to deliver the longest life at a lower maintenance cost. XWear parts are ideal for extreme operating conditions or for simply getting through long harvest seasons without excessive downtime. The option includes highly abrasion-resistant elevator floor segments and chain wear strips, additional hard-surfaced feedrollers, extreme-duty tapered roller bearings, and hardened elevator chain sprockets.

Harvest Monitor™ with SmartClean™ system enables cost saving decisions on harvesting and farming practices

On-screen monitoring, logging, and performance mapping

Exclusive John Deere technology

Exclusive John Deere technology Data-driven decisions

Data-driven decisionsHarvest Monitor features

Harvest Monitor installed on a CH570

Harvest Monitor installed on a CH570

- Optical yield monitor

- Elevator optical extraneous matter (trash) monitor

- Primary extractor cane loss monitor

- Primary extractor residue (trash) discharge monitor

- Fuel per ton monitor

- Pour-rate monitor

- Elevation monitor

- Transport load counter

Optical yield and trash monitor technology

Harvest Monitor

Harvest Monitor High-resolution optical sensors

High-resolution optical sensors Flow of cane being scanned

Flow of cane being scanned Image recognition

Image recognitionSmartClean system, an intelligent way of cleaning cane

SmartClean illustration

SmartClean illustration- Elevator extraneous matter (trash)

- Primary extractor cane loss

- Primary extractor residue discharge

Georeferenced data

StarFire™ 6000 Receiver

StarFire™ 6000 Receiver Sugar cane field yield map

Sugar cane field yield mapOn-screen monitoring

Harvest Monitor screen

Harvest Monitor screen On-screen live cane flow

On-screen live cane flow SmartClean shown on the CommandCenter

SmartClean shown on the CommandCenterTransport load counter

Screen shot showing load counter

Screen shot showing load counter

Harvest Monitor screen shot

Harvest Monitor screen shot

- Harvester pour rate (ton/h)

- Extraneous matter (trash percentage)

- Primary extractor cane loss (index)

- Primary extractor residue discharge (index)

- Fuel consumption (L/ton or gal./ton)

- Yield (ton/ha or ton/acre)

- Transport load count

- Live elevator cane flow video

Data-driven smart decisions on the go

CH570 operating in the field

CH570 operating in the field

Primary extractor fan blades

Primary extractor fan blades Chopper blades

Chopper blades In-field equipment transloading into highway trucks

In-field equipment transloading into highway trucks Multiple harvesters

Multiple harvesters Total mass map (cane and trash)

Total mass map (cane and trash) Cane map

Cane map Elevation monitor

Surveying the field while harvesting

Surveying the field while harvesting Map showing low and high areas

Map showing low and high areas- Row spacing: 1.5 m (4.9 ft)

- Operating speed: 5.4 km/h (3.4 mph)

- Readings per hectare: 4,444

- Represented area: 1.5 m by 1.5 m (4.9 ft by 4.9 ft)

Mapping and data management

Generated maps

Generated maps  Decisions on agronomical practices and logistics

Decisions on agronomical practices and logistics- Yield variability

- Harvester productivity

- Fuel consumption

- Extraneous matter

- Field elevation

Examples of generated maps

Location map using Google Earth™ mapping service

Location map using Google Earth™ mapping service Elevation map

Elevation map  Extraneous matter (trash) map

Extraneous matter (trash) map Fuel-rate map

Fuel-rate map- Chemical application

- Water management

- Cultivating practices

- Gap planting

- Crop renewal

- Variety selection and performance

- Seed rate

- Land leveling

- Field layout

- Equipment operation management

- Logistics

Calibration

CH570 working with weigh wagon

CH570 working with weigh wagon Calibration screen

Calibration screenLarge, premium cab integrates the latest technology with unparalleled comfort

Comfort and convenience

CH570 cab interior

CH570 cab interior

CH570 cab exterior

CH570 cab exterior

Air suspension seat

Air suspension seat Double-tilt telescopic steering column

Double-tilt telescopic steering column Integrated refrigerator

Integrated refrigeratorOptional light-emitting diode (LED) auxiliary lights

Auxiliary LED light on elevator

Auxiliary LED light on elevator Auxiliary LED light on cooling package

Auxiliary LED light on cooling package Optional topper boom light

Optional topper boom light

Versatile displays and intuitive controls

CommandARM™ control panel

CommandARM™ control panel

Digital cornerpost display

Digital cornerpost display

GreenStar™ 3 2630 Display

GreenStar™ 3 2630 Display- Primary extractor fan rpm that will also reduce cane loss while maintaining the highest cleaning levels

- Track harvester maximum speed while the harvesting functions are on

- Engine FieldCruise™ controls in low-yield fields

Multifunction control lever

Multifunction control leverHydrostatic basecutter and chopper maximize efficiency and performance

Basecutter and chopper

Piston motor-driven basecutter

Piston motor-driven basecutter Piston motor-driven chopper

Piston motor-driven chopperBasecutter and buttlifter

Hard-surfaced closed buttlifter

Hard-surfaced closed buttlifter Optional four-bar open buttlifter

Optional four-bar open buttlifterChopper

The modular chopper assembly is independent from the harvester’s main frame, providing a better fit and easier service. It sits on rubber mounts to absorb vibrations. The chopping area is larger with longer blades and contact is even through the whole length. Simpler service, longer component life, uniform higher quality billets, and better feeding into the primary cleaning chamber are the results. Chopper with exclusive sill roller

Chopper with exclusive sill roller- Six blade – 230 to 250 mm (9 to 10 in.)

- Eight blade – 180 to 200 mm (7 to 8 in.)

- Ten blade – 150 to 180 mm (6 to 7 in.)

Sill roller

An exclusive sill roller helps to feed the cane billets into the primary extractor. Even billet movement augments cleaning. It also prevents billet back-feeding and accumulation on the sill.Efficient cleaning system delivers cleanest cane ever

Elevator and cleaning system

High-capacity elevator

High-capacity elevator Primary extractor in action

Primary extractor in actionPrimary extractor

The largest primary extractor in the industry

The largest primary extractor in the industry Wider blades and conical hub

Wider blades and conical hub Smart power primary extractor setting

Smart power primary extractor settingElevator

Robust structural tube frame elevator with perforated floor

Robust structural tube frame elevator with perforated floor Heavy-duty swing table

Heavy-duty swing tableMore features

Grease cylinder chain tensioning

Grease cylinder chain tensioning Nitrogen accumulator

Nitrogen accumulatorSecondary extractor

Secondary extractor and bin flap

Secondary extractor and bin flap Optional without secondary extractor

Optional without secondary extractorJohn Deere-exclusive floating crop divider and contour basecutter height-control technology reduces soil content and cane loss

Optional features

Floating crop dividers and contour basecutter height control

Floating crop dividers and contour basecutter height control

Double click to activate end of row and return to cut

Double click to activate end of row and return to cut

Reduce operator fatigue with the HMS™ headland management system

CH570 Harvester reentering the field

CH570 Harvester reentering the field- Reduces operator inputs when exiting and reentering the field

- Allows operators to focus more on driving the machine and less on resetting harvesting functions

- Allows field supervisors to have operation consistency on all harvesters independently from individual operator’s practices

- Depending on current operator practices, there is the potential for significant fuel savings on the headland by ensuring that harvesting functions are disabled temporarily

Operator activates HMS with one button

Operator activates HMS with one button- Topper direction

- Crop divider pause

- Engine mid throttle

- Side knives engagement

- Steering bias

- Feed train pause

- Primary hood rotate

- Secondary hood rotate

- Topper height

Multifunction control lever

Multifunction control lever- Enable any of or all these functions on the End of Row (2) button:

- Lift the harvester

- Disengage auto basecutter control and floating crop dividers

- Lower engine speed to the mid-throttle setpoint

- Disengage the feed train

- Turn off and lift the topper

- Shut off the side knives

- Predict unloading side for the next row

- Enable any of or all these functions on the Return to Cut (3) button:

- Lower the harvester

- Engage auto basecutter control and floating crop dividers

- Switch suspended floating crop divider (if required)

- Raise engine speed to harvest setting

- Engage the feed train

- Turn on and lower the topper

- Turn on the side knives

- Switch primary and secondary extractor hood direction (if required)

- Switch track steering bias (if required)

HMS screen on the display

HMS screen on the displayExtend elevator and feedroller train life with XWear™ parts

Illustration of CH570 elevator with XWear parts in black

Illustration of CH570 elevator with XWear parts in black Illustration of feedroller train with XWear parts in black

Illustration of feedroller train with XWear parts in black- Double the life compared to standard John Deere components in typical conditions

- Minimize costly downtime

- Reduce repair cost per ton

Offers and Discounts

Related Products

Product features are based on published information at the time of publication. Product features are subject to change without notice. Contact your local John Deere dealer for more information.