- Lawn & Garden

- Agriculture

- Construction

- Landscaping & Grounds Care

- Golf & Sports Turf

- Forestry

- Engines & Drivetrains

- Government & Corporate Sales

- View All Equipment

- View Used Equipment

- Parts

- Manuals & Training

- Warranty & Protection Plans

- Expert Check

- John Deere Connected Support™

- StellarSupport™

- Recalls

- Safety

- Utility Tractors (23-195 Engine HP)

- Specialty Tractors (75-155 Engine HP)

- Row Crop Tractors (145-410 Engine HP)

- 4WD and Track Tractors (390-640 Engine HP)

- Utility Tractors Attachments & Accessories

- Tillage

- Combine Harvesters

- Cotton Harvesters

- Sugar Harvesters

- Hay & Forage

- Planting Equipment

- Seeding Equipment

- Gator™ Utility Vehicles

- Gator™ Attachments & Accessories

- Loaders for Tractors

- Scraper Systems

- Sprayers

- Precision Ag Technology

- Home & Workshop Products

- Used Agriculture Equipment

- INDUSTRIAL DIESEL ENGINES

- Final Tier 4/Stage V

- Interim Tier 4 / Stage III

- Tier 3/Stage III

- Tier 2 and Lesser Regulated

- MARINE ENGINES

- Commercial/Workboat

- Recreational/Pleasure Craft

- GENERATOR DRIVE ENGINES

- Standby/Stationary

- Prime/Portable

- DRIVETRAIN EQUIPMENT

- Pump Drives

- Transmissions

- Axles

- Planetary Gear Drives

- Vehicle Electrification

- TRACTORS & MOWERS

- Ride-On Mowers

- Utility Tractors (22.4-140 Engine HP)

- Specialty Tractors (75-155 Engine HP)

- Residential ZTrak™ Zero-Turn Mowers

- Commercial Mowers

- CONSTRUCTION

- Backhoes

- Compact Track Loaders

- Dozers

- Skid Steers

- Motor Graders

- Wheel Loaders

- UTILITY VEHICLES & ACCESSORIES

- Gator™ Utility Vehicles

- Gator™ Utility Vehicles Attachments & Accessories

- ATTACHMENTS & ACCESSORIES

- Attachments, Accessories & Implements

- Home & Workshop Products

- Front-End Loaders for Tractors

- Application Equipment

- Attachments, Accessories & Implements

- Backhoes

- Dozers

- Engines

- Forwarders

- Gator™ Utility Vehicles

- Hay & Forage

- Combine Harvesters

- Cotton Harvesters

- Sugar Harvesters

- Home & Workshop Products

- Motor Graders

- Mowers

- Planting Equipment

- Precision Ag Technology

- Scraper Systems

- Seeding Equipment

- Skidders

- Sprayers

- Swing Machines

- Tillage

- Tractors

- Home

- active fill control

Active Fill Control

- Automated trailer and truck filling

- Reduce operator stress and fatigue

- Improve harvest efficiency

- Harvest day and night

Features

Focus on what matters

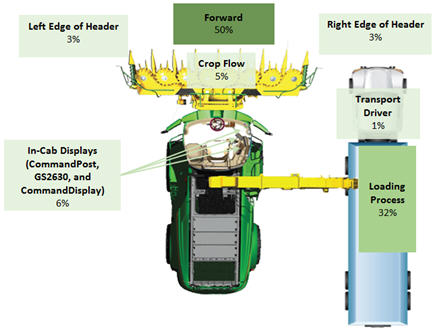

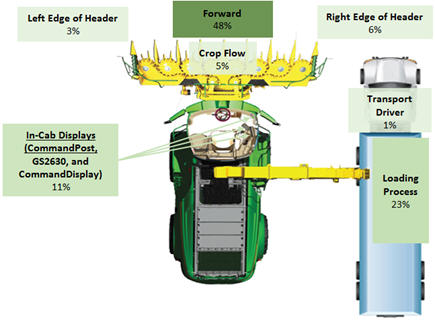

Operating a self-propelled forage harvester (SPFH) is a challenging task that requires an operator to multitask throughout the entire day. Filling the transport truck, coordinating machine logistics, monitoring machine performance, and maximizing throughput are all part of the job. SPFH operators benefit from Active Fill Control, which makes the process easier by reducing the amount of time the operator spends monitoring the truck filling process. Experiments using advanced eye-tracking technology were able to track where an operator’s attention was focused while operating. Operators harvesting corn without Active Fill Control spend about 32 percent of their time watching the loading process. When Active Fill Control is used the operator only spends 23 percent of time monitoring the loading process.

During an 8-hour day, an operator with Active Fill Control will have an extra 40 minutes of time to focus on something else. Through a 20-day harvest season this would amount to more than five hours extra time. This time can be used to maximize throughput, coordinate a truck fleet, monitor forage quality through the HarvestLab™ sensor, or just spend time enjoying the harvest.

Breakdown of an operator’s attention without Active Fill Control

Breakdown of an operator’s attention without Active Fill Control

Breakdown of an operator’s attention with Active Fill Control

Breakdown of an operator’s attention with Active Fill Control

Reduces operator stress and fatigue

A relaxed operator using Active Fill Control

A relaxed operator using Active Fill Control

John Deere Active Fill Control improves operator comfort and reduces operator fatigue in the field. Active Fill Control automatically detects the trailer next to the forage harvester and automatically begins filling with a preselected fill strategy. The operator can focus more on machine behavior and optimization and worry less about the spout and flap steering. After headland turns, the spout will automatically return to the last filling position. The fill status of the trailer can be monitored via video overlay on a separate display, like the GreenStar™ 3 2630 or 4640 Universal Display, causing less tension on operators neck and back. Utilizing these capabilities forage harvesting gets much more convenient, especially during long working hours and for less experienced operators.

Active Fill Control also greatly reduces number of times an operator needs to adjust the spout. During typical operating conditions, an operator will adjust the spout, on average, once every 4 seconds. Throughout a normal day this could amount to more than 6000 button presses on the hydro handle. Active Fill Control can eliminate a vast majority of these presses.

Improves harvest efficiency

Active Fill Control increases efficiency

Active Fill Control increases efficiency

John Deere Active Fill Control is the next step for higher productivity and efficiency during forage harvest. It is impossible to monitor the spout position every second while operating a self-propelled forage harvester (SPFH). Field conditions can vary including hilly terrain, wet soil and soft ground, down crop, obstacles, etc. Also, SPFH operators are challenged with a significant amount of communication and coordination. All this constantly requires the operator to multitask and react quickly to changing conditions. If the spout is improperly aimed for only a few seconds the result can be hundreds of pounds (kilograms) of lost forage.

The operator can experience all the benefits of an automated filling system, including spout steering, flap automation, and fill strategy execution. The camera automatically detects trailers and the current fill level once alongside the forage harvester, ensuring consistent filling of trailers and allowing the operator to fully focus on machine behavior and optimization in order to maintain peak performance at all times.

Harvest day and night

Active Fill Control makes harvesting at night easier

Active Fill Control makes harvesting at night easier

Additional lights improve visibility to the transport vehicle

Additional lights improve visibility to the transport vehicle

Working days during harvest are long and often go through the night.

Active Fill Control includes an additional light-emitting diode (LED) spout light package that ensures a steady fill, even in darkness. The design has also been optimized to ensure functionality under varying light, dust, shading, or rain conditions.

Set up with ease

John Deere Active Fill Control is a fully integrated solution from John Deere. Once installed, it can be fully utilized in three easy steps:

| Step 1: | Set up desired fill level and fill strategy in the self-propelled forage harvester (SPFH) CommandCenter™ display. |

| Step 2: | Engage Active Fill Control on the hydro handle |

| Step 3: | Begin experiencing all the benefits of Active Fill Control |

As soon as Active Fill Control is engaged by the operator, the system will continuously look for a trailer in the camera field of view and fill it automatically, once detected. Never has forage harvesting been easier.

Monitor the fill progress on a video screen

The forage harvester operator has the option to simultaneously monitor the filling progress on any video screen mounted in the cab. No need to turn the head anymore and lose view of the crop flow.

The operator will see the following information on the video screen:

- Video picture of camera view

- Overlay of targeted trailer edges

- Overlay of filling status

- Icon for Active Fill Control status

- Icon for current fill strategy

- Icon for current offset adjustment

- Icon of current camera quality

Generation 4 Display compatibility

This document lists all the compatible equipment approved with the software update 19-2 release, and is subject to change with newer software updates. To ensure complete and proper compatibility, the most current version of implement control unit software, Generation 4 Display software, or compatible farm management information software (FMIS) should be used. Non-current software versions will require an update before support can be provided. Unapproved software version configurations will not be supported.

The software update 19-2 release is only compatible with 4600 CommandCenter™ v2 processors. Software update 17-2 is the last release that was compatible with 4600 v1 processors.

Server serial numbers are as follows:

- v1 = RWG prefix

- v2 = PCG prefix

Machine compatibility

John Deere Large Ag Tractors

| John Deere Large Ag Tractors (list of all automatically detected machines) |

Model year | CommandCenter display | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240 | ||

| 9R/9RT/9RX Series | 2018 and newer | X | — | X | X |

| 9R/9RT/9RX Series | 2015-2017 | * | — | X | X |

| 9R/9RT Series | 2012-2014 | — | — | X | X |

| 9030/9030T Series | 2008 and newer | — | — | X | X |

| 9020/9020T Series | 2002-2007 | — | — | X | — |

| 9000 Series | 1997-2001 | — | — | X | — |

| 9000T Series | 2000-2001 | — | — | X | — |

| 8R/8RT Series | 2018 and newer | X | — | X | X |

| 8R/8RT Series | Mid-2014 – 2017 | * | — | X | X |

| 8R/8RT Series | 2010-2013 | — | — | X | X |

| 8030/8030T Series | 2006 and newer | — | — | X | X |

| 8020/8020T Series | 2002-2005 | — | — | X | — |

| 8010/8010T Series | 2000-2002 | — | — | X | — |

| 8000 Series | 1994 | — | — | X | — |

| 8000T Series | 1997-1999 | — | — | X | — |

| 7R Series | 2018 and newer | X | X | X | X |

| 7R Series | 2014-2017 | * | — | X | X |

| 7R Series | 2011-2013 | — | — | X | X |

| 7030 Series | 2007 and newer | — | — | X | X |

| 7030 Series (Large Frame) | 2007 and newer | — | — | X | X |

| 7030 Series (Small Frame) | 2006 and newer | — | — | X | X |

| 7010 Series | 1997-2003 | — | — | X | — |

| 7000 Series | 1992-1996 | — | — | X | — |

| 6030 Series (Small Frame) | 2006 and newer | — | — | X | X |

| 6000 Series | 1992-1998 | — | — | X | — |

| 6010 Series | 1999-2002 | — | — | X | — |

| 6R Series | 2018 and newer | X | X | X | X |

| 6R Series (Final Tier 4) | 2015-2017 | * | — | X | X |

| 6R Series (Interim Tier 4) | 2013-2015 | — | — | X | X |

| 6M Series | 2013 and newer | — | — | X | X |

| 6J Series | 2018 and newer | — | — | X | X |

| 5R Series | 2019 and newer | — | — | X | X |

*NOTE: For latest Precision Ag functionality, update machines equipped from the factory with v1 processor to v2. The 4640 Universal Display is not compatible with SeedStar™ 4HP Planters when installed on 00, 10, and 20 Series Tractors.

John Deere Self-Propelled Sprayers

| John Deere self- propelled sprayers |

Model year | CommandCenter | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240 | ||

| 4 Series Sprayers | 2018 and newer | X | — | — | — |

| 4 Series Sprayers | 2013 – 2017 | — | — | X | — |

| 4940 | 2012 – 2014 | — | — | X | — |

| 4630 | 2008 and newer | — | — | X | — |

| 4730 | 2008 and newer | — | — | X | — |

| 4830 | 2008 – 2014 | — | — | X | — |

| 4930 | 2008 – 2013 (SN 4000+) | — | — | X | — |

| R4040i | 2014 and newer | — | — | X | — |

| R4050i | 2017 and newer | — | — | X | — |

| Hagie™ sprayers | 2014 and newer | Compatible with GreenStar™ 3 2630 Displays and 4640 Universal Displays* | |||

*NOTE: When using the 4640 Universal Display on a Hagie Sprayer, additional mounting and harnessing may be required.

- 4640 Ram™ Mount – SJ34503

- 4640 power/video harness – BPF11527 (1-3 video plus machine power), PF90687 (machine power only)

NOTE: Current John Deere/Hagie field kits only offer GreenStar 3 2630 Display parts.

NOTE: AutoTrac™ Vision/AutoTrac RowSense and multi-rank section control are not supported on Hagie at this time.

NOTE: VIN detection is not supported on Hagie Sprayers at this time.

John Deere Self-Propelled Forage Harvesters (SPFH)

John Deere Self-Propelled |

Model year | CommandCenter | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240 | ||

| 9000 Series SPFH | 2019 and newer | — | — | X | — |

| 8000 Series SPFH | 2015 and newer | — | — | X | — |

John Deere combines

| John Deere combines | Model year | CommandCenter | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240 | ||

| S700 Series | 2018 and newer | X | — | — | — |

| S430 and S440 | 2017 and newer | X | — | — | — |

| S600 Series | 2012 – 2017 | — | — | X | X |

| T-Series | 2012 and current | — | — | X | X |

| 70 Series | 2008 – 2013 | — | — | X | X |

NOTE: Competitive equipment may be compatible with 4640 Universal Display and 4240 Universal Display. For additional compatibility information, contact a John Deere dealer.

Equipment compatibility

John Deere planters

SeedStar™ 4HP planters are only compatible with 4600 CommandCenter displays with a version 2 (v2) processor and 4640 Universal Displays. Displays should be running Generation 4 OS software version 10.10.404-390 or newer and the most current version of tractor applications to be compatible with SeedStar 4HP planter applications. Additionally, dual-display mode is available for use with SeedStar 4HP planter applications, along with Generation 4 Extended Monitor. SeedStar 4HP planters are compatible with no more than two GreenStar Rate Controllers.

The SeedStar 2 configuration below is available only on factory-installed model year 2011 and newer planters and may be field-installed on model year 2009 and 2010 planters. Green PM/PA controllers (factory-installed on model year 2009 and 2010 planters) are not supported with a Generation 4 display.

A Service ADVISOR™ tool (available at a John Deere dealer) is needed to update SeedStar 2, SeedStar XP, and SeedStar 3 HP software. Documentation is not supported when using a rate controller to control row clutches on a John Deere planter.

| John Deere planters | Control unit name | Software version (or newer) | CommandCenter display | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240* | |||

| SeedStar 2 |

Black PM1 | 22.0 | X | X | X | X |

| Black PA1, (if available PA 2) | 22.0 | X | X | X | X | |

| Green PM1 | 10.11 | — | — | — | — | |

| Green PA1 (if available PA 2) | 10.11 | — | — | — | — | |

| SeedStar XP |

Black PM1 | 22.0 | X | X | X | X |

| Black PA1, (if available PA 2) | 22.0 | X | X | X | X | |

| PM2 | 7.0 | X | X | X | X | |

| SeedStar 3 HP |

Planter Main A (PCMA) | 5.0 | X | X | X | X |

| Planter Main B (PCMB or MMC) | 8.0 | X | X | X | X | |

| Row-unit Controller (RUC) | 2.0 | X | X | X | X | |

| EPG | 3.0 | X | X | X | X | |

| SeedStar 4HP |

Planter Apps | 10.4.2-29 | X | — | X | — |

| Planter Main A (PMCA) | 5.0 | X | — | X | — | |

| Planter Main B (PMCB or MMC) | 6.0 | X | — | X | — | |

| Row-unit Controller (RUC) | 3.0 | X | — | X | — | |

| Electrical Power Generation (EPG) | 5.0 | X | — | X | — | |

| Electrical Power Module, 2 (PC2) | 3.0 | X | — | X | — | |

*NOTE: For implements requiring ground speed input (radar), utilizing a 4240 Universal Display may require an additional 4240 Radar speed kit.

John Deere Air Seeders

The C850 Air Cart requires a 4600/4200 CommandCenter Display or a 4640/4240 Universal Display. GreenStar 3 2630 monitors are not supported. Additionally, C850 Air Carts and AutoTrac Implement Guidance (passive) are compatible with software update 18-2 and newer.

| John Deere Air Seeder | Model year/control unit name | Software version (or newer) | CommandCenter | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240* | |||

| C850 Air Cart |

Cart Master Controller (CMC) | 12 | X | X | X | X |

| Mini Tank Controller (TXC) | 6 | X | X | X | X | |

| Front, Middle, Rear Tank Controller (TCU) | 6 | X | X | X | X | |

| 1870 Seeding Tool – TruSet™ system | 2017 and newer (IDC) | 5.0 | X | X | X | X |

| 1870 Seeding Tool – RelativeFlow™ blockage sensors | 2017 and newer (BMU) | 4.0 | X | X | X | X |

| 1910 Air Cart – ground drive | 2009 and newer | 3.0 | X | X | X | X |

| 1910 Air Cart – hydraulic drive |

2013 and newer | 8.00 | X | X | X | X |

| Seeding tools with air-run blockage – primary blockage |

2009 and newer (BMU) | 12.0 | X | X | X | X |

| Seeding tools with air-run blockage – air-run blockage | 2009 and newer (BMU) | 12.0 | X | X | X | X |

| Member Module | 5.0 | X | X | X | X | |

| 1990 Central Commodity System (CCS™) |

2009 and newer (BMU) | 12.0 | X | X | X | X |

| N500C Series | Seeding apps | 10.1.495-31 | X | — | X | — |

| SMCA or SMC | 2.0 | X | — | X | — | |

| SMCB or BMU | 2.0 | X | — | X | — | |

| EPG | 2.0 | X | — | X | — | |

*NOTE: For implements requiring ground speed input (radar), utilizing a 4240 Universal Display may require an additional 4240 Radar speed kit.

John Deere Tillage

| John Deere Tillage | Control unit name | Software version (or newer) | CommandCenter | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240 | |||

| 2430 with TruSet | Tillage Controller 1 (TC1) | 2.14K | X | X | X | X |

*NOTE: For implements requiring ground speed input (radar), utilizing a 4240 Universal Display may require an additional 4240 Radar speed kit.

John Deere Round Balers

| John Deere Round Balers | Control unit name | Software version (or newer) | CommandCenter | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240 | |||

| 9 Series Premium |

Baler Automation | 7.16 | X | X | X | X |

| V451R/V461R | Baler Automation | 11.5 | X | X | X | X |

John Deere Large Square Balers

| John Deere Large Square Balers Including Harvest Tec applicator and PhiBer accumulator |

Control unit name | Software version (or newer) | CommandCenter | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240 | |||

| 0 Series | Gen 4 VT | 3.04 | X | X | X | X |

| 1 Series |

Gen 4 VT | 5.07 | X | X | X | X |

Precision Ag Technology software compatibility

| John Deere control units | Control unit name | Software version (or newer) | CommandCenter display | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240 | |||

| *StarFire 6000 Receiver | — | 4.10J | X | X | X | X |

| StarFire 3000 Receiver | — | 2.32H | X | X | X | X |

| *Modular Telematics Gateways (MTG) – 3G | — | 21.03 | X | X | X | X |

| *MTG – 4G | — | 25.01.746 | X | X | X | X |

| GreenStar Rate Controller | — | 3.70K | X | X | X | X |

| GreenStar Rate Controller Dry | — | 2.11A | X | X | X | X |

| *John Deere Rate Controller 2000 | — | 1.13A | X | X | X | X |

| *AutoTrac Universal 200 | — | 2.30A | — | — | X | X |

| *AutoTrac Universal 300 | — | 3.22O | — | — | X | X |

| AutoTrac Controller 250 | — | 11933B | — | — | X | X |

| *AutoTrac Controller – Deere | — | 1.11B | — | — | X | X |

| AutoTrac Controller – Raven | — | 3.2.29 | — | — | X | X |

| AutoTrac Controller – Reichhardt® | — | SW 1.3 | — | — | X | X |

| AutoTrac RowSense™ | RG3 | AKK15783F | X | — | X | — |

| AutoTrac Vision | VGC | 4.01L | X | — | X | — |

| AutoTrac Turn Automation | — | 19-2 | X | — | X | — |

| AutoTrac Implement Guidance | — | 19-2 | X | — | X | — |

| Active Implement Guidance (VT) | Application 1100 | 2.71 T | X | X* | X | X* |

| iGrade™ | Application 1100 | 2.71 T | X | X | X | X |

| Distance Trip | Application 1100 | 2.71 T | X* | X | X | X |

| Gen 4 Extended Monitor | X | — | X | — | ||

| Wireless Data Server | Wireless Data Server | 1.541.2 (Planting) |

X | — | X | — |

| Mobile Data Transfer | MyTransfer™ app | 3.8.6 (iOS®) |

X | X | X | X |

| Connect Mobile app | Connect Mobile app | 8.0.1 or newer | X | — | X | — |

| Connect Mobile server | Connect Mobile server | 2.3.87-1 | X | — | — | — |

| Mobile Weather | Application 1120 | 1.51 V | X | X* | X | X* |

*NOTE: See additional information below.

StarFire Receivers

StarFire Receivers can be updated in the following ways:

- Receiver USB port (available only for StarFire 6000 Receivers)

- Generation 4 display USB port

- Remote software updates application (in ISOBUS VT app)

Additionally, StarFire iTC Receivers are no longer supported with software update 2017-1 and newer software. StarFire 6000 Receivers require software version 3.80F or higher when used with AutoTrac Implement Guidance.

John Deere Operations Center

To use RDA on a Generation 4 CommandCenter Display with a GreenStar 3 2630 Display connected in the same machine, GreenStar 3 2630 software version 3.22.1095 (SU2014-1) or higher is required (for 4600 CommandCenter Display and 4640 Universal Display only).

GreenStar Rate Controller and GreenStar Rate Controller Dry

GreenStar Rate Controller Dry is supported with display software update 2017-2 and newer. The 4600 and 4200 CommandCenter Displays and 4640 and 4240 Universal Displays support documentation and section control of up to five GreenStar Rate Controller units.

To update the GreenStar Rate Controller and GreenStar Rate Controller Dry, utilize a Generation 4 Display USB port. John Deere dealers can also utilize Service ADVISOR™. GDC 2.11A was the last software version available through Software Manager. GDC 2.20A has been available since spring 2015 and contains diagnostic language updates. This software can only be obtained through Service ADVISOR.

John Deere Rate Controller 2000

The Generation 4 Displays and John Deere Rate Controller 2000 can support documentation and control up to five operations. ISO controllers such as SeedStar or TruSet can be used alongside a John Deere Rate Controller 2000 that is documenting additional operations. The John Deere Rate Controller 2000 will not control the planter clutches or half-, third-, or quarter-width disconnects on a John Deere planter.

AutoTrac™ Vision

AutoTrac Vision Guidance Camera 19-1 software 4.01L is only compatible with RowGuidance 3 Controller software AKK15783F and GreenStar 3 2630 17-1 software 3.34.1345 or newer and Generation 4 18-1 software 10.10.404-345 or newer.

AutoTrac Universal 200, AutoTrac Universal 300, and AutoTrac Controller

AutoTrac Universal 200, AutoTrac Universal 300, and AutoTrac Controllers are for use with the 4640 Universal Display and 4240 Universal Display. Please see a John Deere dealer for exact model compatibility.

ISOBUS implements

Generation 4 Displays are compatible with one Agricultural Industry Electronics Foundation (AEF) certified ISOBUS implement; AEF-certified ISOBUS implements with Task Controller Section Control (TC-SC) functionality and AEF certification for TC-SC include sprayers, fertilizer spreaders, planters, seeders, manure applicators, etc. For third-party FMIS compatibility, reference the John Deere Operations Center.

A software update performed by an authorized ISOBUS implement dealer may be required to obtain compatible software. ISOBUS implements must be certified through the Agricultural Industry Electronics Foundation (AEF) to be recognized by the Generation 4 CommandCenter display. Visit www.aef-online.org for more information; visit www.aef-isobus-database.org for an active list of compatible implements.

ISOBUS implements with VT4 are now supported by Generation 4 Displays. Generation 4 Displays still support older VT versions (example: VT2 and VT3). If an implement is not loading after updating to Generation 4 software update 2017-2 (or newer on 4600 CommandCenter v2 processors), it is recommended that the implement manufacturer be contacted to get a software version that is either VT3 or VT4.

Extended monitor

When using an extended monitor with equipment visualized in ISOBUS VT Viewer and applying VT run page modules to two run pages shown at the same time, the extended monitor’s VT modules will not update. To mitigate this, only view VT modules on one run page at a time.

Implements without controllers

Implements without controllers can be documented as a stand-alone operation or with a rate controller from John Deere. Additionally, multiple implements without controllers cannot be documented together.

AutoTrac Implement Guidance (passive)

AutoTrac Implement Guidance is compatible with SeedStar 3HP, SeedStar 2 and SeedStar XP.

AutoTrac Implement Guidance is compatible with C850 Tow-Behind Air Carts with software update 18-2.

AutoTrac Implement Guidance is not compatible with the SeedStar 4 HP planters.

AutoTrac Implement Guidance is not compatible on 4240 Universal Displays for shared signal applications.

AutoTrac Turn Automation

To use the AutoTrac Turn Automation application, specific compatibility is required. AutoTrac Turn Automation is compatible with the following machines:

- 8030 Series Tractors

- 9030 Series Tractors (if equipped with PowerShift™ transmission)

- Model year 2012 and newer 6R Tractors (if equipped with Infinitely Variable Transmission [IVT™] and ITEC™ functionality)

- Model year 2011 and newer 7R Tractors (if equipped with CommandQuad™ transmission, e23™ PowerShift transmission, or IVT)

- Model year 2010 and newer 8R/RT Tractors

- Model year 2012 and newer 9R/RT/RX Tractors

NOTE: Integrated tractor IMS must be turned off on 30-Series Tractors to use AutoTrac Turn Automation on the Generation 4. Integrated Tractor iTEC must be turned off on the following tractors to use AutoTrac Turn Automation on the Generation 4:

- Model year 2012-2014 6R

- Model year 2011-2013 7R

- Model year 2010-2013 8R

- Model year 2012-2014 9R

NOTE: If instead an operator chooses to use the machine’s integrated IMS/iTEC functionality, then AutoTrac Turn Automation and iTEC must be turned off in the Generation 4 Universal Display.

AutoTrac Turn Automation is compatible with SeedStar 3HP, SeedStar 2 and SeedStar XP.

AutoTrac Turn Automation is NOT compatible with SeedStar 4HP planters.

Distance Trip documentation

A UCC2 Application Controller 1100 with 19-2 software running on a 4600 CommandCenter v2 server enables documentation of field operations. If a UCC2 replaces a UCC1 Application Controller 1100 on a CommandCenter v1 server, documentation is not available. Refer to Tech Manual Bulletin 137919 to determine server type.

Camera compatibility

Voyager® cameras are supported on Generation 4 Displays. All other camera types are not supported.

Non-John Deere Precision Ag

4600 CommandCenter v2 and the 4640 Universal Display are compatible with the following RS-232 configurations with software update 18-2 and newer:

- GPS receivers with serial port connection

- Will not enable AutoTrac guidance functionality

- Raven RS-232 control units (440, 450, or 660) on tractors configured as implement-based applications

- Generation 4 displays are not compatible with the DN345 Drawn Dry Spreader at this time.

Machine Communication Radio (MCR)

Generation 4 displays are not compatible with MCR.

RAM is a trademark of National Products Inc. Hagie is a trademark of Hagie Manufacturing Company, LLC and similar to John Deere branded equipment, John Deere will support Hagie equipment. Reichhardt is a trademark of Reichhardt GmbH Steuerungstechnik. iOS is a trademark of Cisco Technology, Inc. used under license by Apple Inc. Android is a trademark of Google LLC. Voyager is a trademark of ASA Electronics, LLC.

Related Products

-

4200 CommandCenter™ Display

4200 CommandCenter™ Display -

4240 Universal Display

4240 Universal Display -

4600 CommandCenter™ Display

4600 CommandCenter™ Display -

4640 4640 Universal Display

4640 4640 Universal Display -

Active Fill Control

Active Fill Control -

Active Implement Guidance

Active Implement Guidance -

AutoTrac™ Turn Automation

AutoTrac™ Turn Automation -

AutoTrac™ Implement Guidance

AutoTrac™ Implement Guidance -

AutoTrac™ Activation

AutoTrac™ Activation -

AutoTrac™ Universal 300

AutoTrac™ Universal 300 -

AutoTrac™ Controller

AutoTrac™ Controller -

AutoTrac™ RowSense™

AutoTrac™ RowSense™ -

AutoTrac™ RowSense™ – Sprayer

AutoTrac™ RowSense™ – Sprayer -

AutoTrac™ Universal 200

AutoTrac™ Universal 200 -

AutoTrac™ Vision

AutoTrac™ Vision -

Gen 4 CommandCenter™ Premium Activation

Gen 4 CommandCenter™ Premium Activation -

Gen 4 Extended Monitor

Gen 4 Extended Monitor -

John Deere Machine Sync

John Deere Machine Sync -

StarFire RTK Radio 450

StarFire RTK Radio 450 -

StarFire™ 6000 Receiver

StarFire™ 6000 Receiver -

StarFire™ RTK

StarFire™ RTK -

StarFire™ RTK Radio 900

StarFire™ RTK Radio 900

Product features are based on published information at the time of publication. Product features are subject to change without notice. Contact your local John Deere dealer for more information.