Back

- Lawn & Garden

- Agriculture

- Construction

- Landscaping & Grounds Care

- Golf & Sports Turf

- Forestry

- Engines & Drivetrains

- Government & Corporate Sales

- View All Equipment

- View Used Equipment

- Parts

- Manuals & Training

- Warranty & Protection Plans

- Expert Check

- John Deere Connected Support™

- StellarSupport™

- Recalls

- Safety

- Utility Tractors (23-195 Engine HP)

- Specialty Tractors (75-155 Engine HP)

- Row Crop Tractors (145-410 Engine HP)

- 4WD and Track Tractors (390-640 Engine HP)

- Utility Tractors Attachments & Accessories

- Tillage

- Combine Harvesters

- Cotton Harvesters

- Sugar Harvesters

- Hay & Forage

- Planting Equipment

- Seeding Equipment

- Gator™ Utility Vehicles

- Gator™ Attachments & Accessories

- Loaders for Tractors

- Scraper Systems

- Sprayers

- Precision Ag Technology

- Home & Workshop Products

- Used Agriculture Equipment

- INDUSTRIAL DIESEL ENGINES

- Final Tier 4/Stage V

- Interim Tier 4 / Stage III

- Tier 3/Stage III

- Tier 2 and Lesser Regulated

- MARINE ENGINES

- Commercial/Workboat

- Recreational/Pleasure Craft

- GENERATOR DRIVE ENGINES

- Standby/Stationary

- Prime/Portable

- DRIVETRAIN EQUIPMENT

- Pump Drives

- Transmissions

- Axles

- Planetary Gear Drives

- Vehicle Electrification

- TRACTORS & MOWERS

- Ride-On Mowers

- Utility Tractors (22.4-140 Engine HP)

- Specialty Tractors (75-155 Engine HP)

- Residential ZTrak™ Zero-Turn Mowers

- Commercial Mowers

- CONSTRUCTION

- Backhoes

- Compact Track Loaders

- Dozers

- Skid Steers

- Motor Graders

- Wheel Loaders

- UTILITY VEHICLES & ACCESSORIES

- Gator™ Utility Vehicles

- Gator™ Utility Vehicles Attachments & Accessories

- ATTACHMENTS & ACCESSORIES

- Attachments, Accessories & Implements

- Home & Workshop Products

- Front-End Loaders for Tractors

- Application Equipment

- Attachments, Accessories & Implements

- Backhoes

- Dozers

- Engines

- Forwarders

- Gator™ Utility Vehicles

- Hay & Forage

- Combine Harvesters

- Cotton Harvesters

- Sugar Harvesters

- Home & Workshop Products

- Motor Graders

- Mowers

- Planting Equipment

- Precision Ag Technology

- Scraper Systems

- Seeding Equipment

- Skidders

- Sprayers

- Swing Machines

- Tillage

- Tractors

- Home

- f441r round baler euro spec

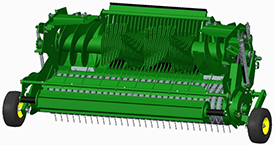

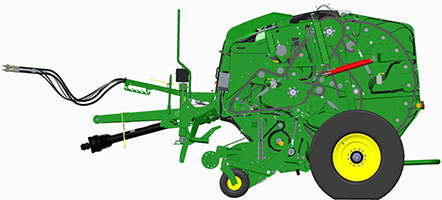

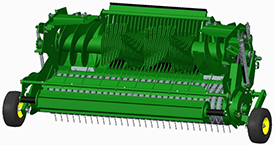

F441RRound Baler

- Built for high volume use

- Premium specification

- Excellent in all kinds of crop

F441R

Features

Features

Expand All

Collapse All

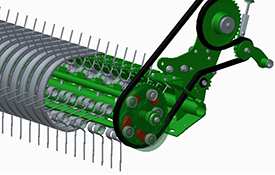

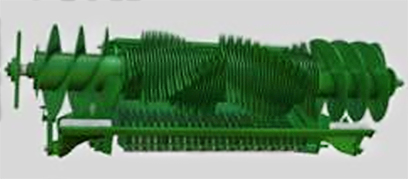

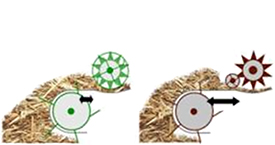

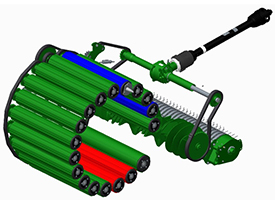

Large-diameter stripper and five teeth bars provide high picking capacity

Large-diameter stripper and five teeth bars provide high picking capacity

Forged cam-track links improve reliability

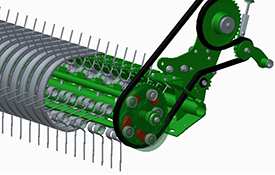

The F441R Baler uses the premium pickup that is also equipped on high-spec V4X1R Variable Chamber Balers. To fit all conditions, the baler is available with a 2.0-m (6.56-ft) or 2.20-m (7.22-ft) width.

The pickup, driven by 19.05-mm (0.75-in.) heavy-duty chains, features five tine (four on the F441M) bars with a low rotating speed. The large-diameter strippers allow five tine bars in the pickup. The picking capacity is 25 percent higher than for the F441M. With bearings added to the cam track, all of these features provide a smooth and quiet ride with extended uptime.

In addition to the high-spec features, the F441R benefits from stainless-steel strippers, a market exclusive. Stainless steel provides the following advantages:

Forged cam-track links improve reliability

The F441R Baler uses the premium pickup that is also equipped on high-spec V4X1R Variable Chamber Balers. To fit all conditions, the baler is available with a 2.0-m (6.56-ft) or 2.20-m (7.22-ft) width.

The pickup, driven by 19.05-mm (0.75-in.) heavy-duty chains, features five tine (four on the F441M) bars with a low rotating speed. The large-diameter strippers allow five tine bars in the pickup. The picking capacity is 25 percent higher than for the F441M. With bearings added to the cam track, all of these features provide a smooth and quiet ride with extended uptime.

In addition to the high-spec features, the F441R benefits from stainless-steel strippers, a market exclusive. Stainless steel provides the following advantages:

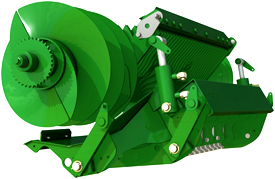

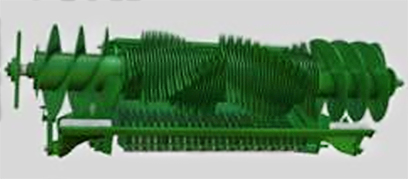

MaxiCut™ HC 25 Premium has a single axis for rotor and converging augers

MaxiCut™ HC 25 Premium has a single axis for rotor and converging augers

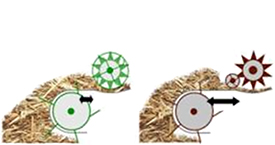

HC rotor limits plugs

To maximize productivity in the toughest swaths, the F441R Baler features an HC Premium rotor design. Converging augers are aligned with the rotor, limiting the free space between pickup teeth and rotor. Plugging risk is also decreased and crop transfer is highly improved. The simple HC Premium rotor design also reduces the number of moving parts and provides reliability. For example, stress on the rotor is distributed along the rotor to avoid overhang load on the bearings. Additionally, all rotors feature tines that are made of Hardox® wear plate which drastically improves wear resistance, especially in rocky fields.

The F441R is only available with a precutter, offering space between knives as short as 40 mm (1.57 in.) or 80 mm (3.15 in.).

HC rotor limits plugs

To maximize productivity in the toughest swaths, the F441R Baler features an HC Premium rotor design. Converging augers are aligned with the rotor, limiting the free space between pickup teeth and rotor. Plugging risk is also decreased and crop transfer is highly improved. The simple HC Premium rotor design also reduces the number of moving parts and provides reliability. For example, stress on the rotor is distributed along the rotor to avoid overhang load on the bearings. Additionally, all rotors feature tines that are made of Hardox® wear plate which drastically improves wear resistance, especially in rocky fields.

The F441R is only available with a precutter, offering space between knives as short as 40 mm (1.57 in.) or 80 mm (3.15 in.).

Double-heat treatment for concise cut and long life

Double-heat treatment for concise cut and long life

Individual knife security for quality forage

The F441R Balers are efficient in baling a high amount of cut silage. The MaxiCut HC 13 Premium and MaxiCut HC 25 Premium feature exclusive high-quality knives, providing several advantages:

Individual knife security for quality forage

The F441R Balers are efficient in baling a high amount of cut silage. The MaxiCut HC 13 Premium and MaxiCut HC 25 Premium feature exclusive high-quality knives, providing several advantages:

Knife activation from the BaleTrak™ monitor

Knife activation from the BaleTrak™ monitor

Knife sets from the cab with MaxiCut HC 25 Premium

The F441R can be used on several kinds of crops, in which knives can be engaged or removed. No matter the rotor type or monitor, this operation is easily managed from the cab.

When using the MaxiCut HC 25 Premium precutter, crops can be cut as short as 40 mm (1.57 in.), but only half of the knives can be engaged. This system proposes to use two different sets of knives for the same cutting width, to allow the use of sharp knives longer. By using sharpened knives versus blunt, fuel consumption can be decreased by up to 10 percent.

Knife sets from the cab with MaxiCut HC 25 Premium

The F441R can be used on several kinds of crops, in which knives can be engaged or removed. No matter the rotor type or monitor, this operation is easily managed from the cab.

When using the MaxiCut HC 25 Premium precutter, crops can be cut as short as 40 mm (1.57 in.), but only half of the knives can be engaged. This system proposes to use two different sets of knives for the same cutting width, to allow the use of sharp knives longer. By using sharpened knives versus blunt, fuel consumption can be decreased by up to 10 percent.

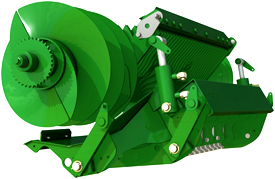

Drop floor covers rotor full width

Drop floor covers rotor full width

Parallel kinematics avoids narrowing

No matter the operator experience, plugs can still occur, especially with large silage swaths. The F441R is equipped as a base with a drop floor unplugging system. The F441R drop floor features exclusive advantages, such as:

Parallel kinematics avoids narrowing

No matter the operator experience, plugs can still occur, especially with large silage swaths. The F441R is equipped as a base with a drop floor unplugging system. The F441R drop floor features exclusive advantages, such as:

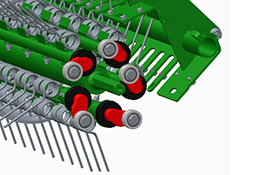

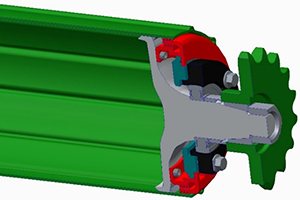

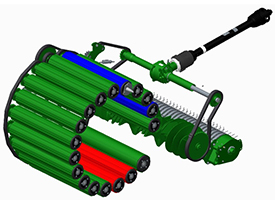

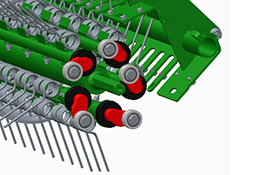

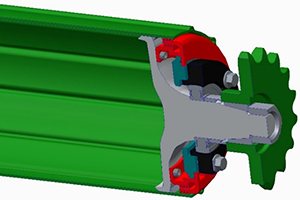

12 ribs roll

12 ribs roll

Bearings protection feature chicane and lips plastic seal

In order to provide high-quality rolls, the F441R rolls are not two half shelves welded together. John Deere only uses tubes that are ribbed to better grip the crops. The dedicated manufacturing process produces an accurate cylindrical shape, avoiding vibration.

Bearings protection feature chicane and lips plastic seal

In order to provide high-quality rolls, the F441R rolls are not two half shelves welded together. John Deere only uses tubes that are ribbed to better grip the crops. The dedicated manufacturing process produces an accurate cylindrical shape, avoiding vibration.

Fully greaseable bearings can be replaced easily

All rolls are now assembled on larger bearings that are 50 mm (1.97 in.) in diameter with a 90-mm (3.54-in.) width or 55 mm (2.17 in.) in diameter with a 100-mm (3.94-in.) width. On the left side of the machine the bearing load capacity has been increased by 20 percent and on the right side by 35 percent. All bearings are greaseable. Additionally, lips plastic seal integrated in chicane locks off debris, silage juice, and moisture from bearings.

In order to improve the machine’s durability, roll bearings feature 20 percent more load capacity on the left side of the machine and 35 percent more on the right side.

Fully greaseable bearings can be replaced easily

All rolls are now assembled on larger bearings that are 50 mm (1.97 in.) in diameter with a 90-mm (3.54-in.) width or 55 mm (2.17 in.) in diameter with a 100-mm (3.94-in.) width. On the left side of the machine the bearing load capacity has been increased by 20 percent and on the right side by 35 percent. All bearings are greaseable. Additionally, lips plastic seal integrated in chicane locks off debris, silage juice, and moisture from bearings.

In order to improve the machine’s durability, roll bearings feature 20 percent more load capacity on the left side of the machine and 35 percent more on the right side.

Blue and red rolls are heavy duty

All rolls feature upgraded quality steel providing 20 percent higher yield strength. Depending on their positions, the rolls do not all carry the same load and stress, specifically:

Blue and red rolls are heavy duty

All rolls feature upgraded quality steel providing 20 percent higher yield strength. Depending on their positions, the rolls do not all carry the same load and stress, specifically:

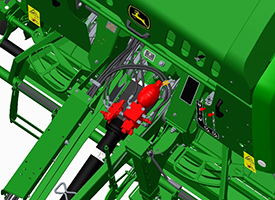

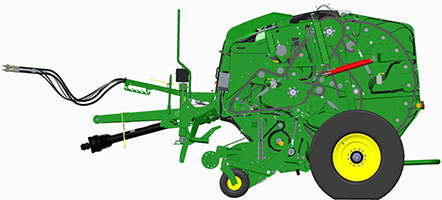

Damped gate cylinders

Opening and closing gate motion is driven by damped cylinders, which simultaneously provide very fast cycles at around 6 seconds to open and close the gate (can depend on tractor hydraulic capacity) and minimize chocks at the end of motion due to gate inertia. High machine productivity is achieved while machine frame stress is decreased.

Damped gate cylinders

Opening and closing gate motion is driven by damped cylinders, which simultaneously provide very fast cycles at around 6 seconds to open and close the gate (can depend on tractor hydraulic capacity) and minimize chocks at the end of motion due to gate inertia. High machine productivity is achieved while machine frame stress is decreased.

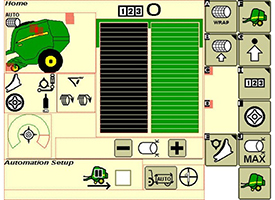

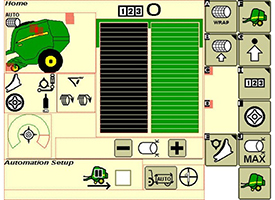

Green column indicates bale diameter target – black column indicates bale diameter status

Green column indicates bale diameter target – black column indicates bale diameter status

Bales density can be adjusted from ISOBUS monitors through proportional density valve

The balers allow operators to maximize bale weight and minimize total production costs due to shipping and storage needs. The bale diameter can be easily adjusted from between 1.25 m to 1.35 m (4.10 ft to 4.43 ft) from the monitor. The settings (seven steps) allow an accurate and quick choice. The bale diameter is controlled by contactless sensors, which provide long durability and error proof monitoring.

The bale density and size are not directly linked on the F441R and C441R Balers. Depending on the crop type, operators can independently choose a small-diameter bale with the highest density, a 1.30-m (4.27-ft) bale with higher density, or large-diameter bale with low density. A pressure gauge located on the front of the baler or on the monitor screen communicating the density is linked to the density harness. The density is easily adjusted from the monitor on an ISOBUS baler or by a knob located directly on the density valve in front of the baler. No tools are required.

The density harness is a closed and isolated circuit, meaning that there is no continuous oil flow requiring extra power consumption.

The density booster is installed in base on the F441R Baler. The hydraulic device maintains high hydraulic pressure in the density bracket during the complete baling process, even when using a tractor with decreased hydraulic performance.

Thanks to the density booster, the tailgate stays firmly closed from the start of bale formation to the end of the tying process. This increases the bale density and weight. The effect of the density booster is especially visible on small bales of 1.25 m (4.10 ft).

By limiting the trapped air, forage quality is also highly enhanced.

Bales density can be adjusted from ISOBUS monitors through proportional density valve

The balers allow operators to maximize bale weight and minimize total production costs due to shipping and storage needs. The bale diameter can be easily adjusted from between 1.25 m to 1.35 m (4.10 ft to 4.43 ft) from the monitor. The settings (seven steps) allow an accurate and quick choice. The bale diameter is controlled by contactless sensors, which provide long durability and error proof monitoring.

The bale density and size are not directly linked on the F441R and C441R Balers. Depending on the crop type, operators can independently choose a small-diameter bale with the highest density, a 1.30-m (4.27-ft) bale with higher density, or large-diameter bale with low density. A pressure gauge located on the front of the baler or on the monitor screen communicating the density is linked to the density harness. The density is easily adjusted from the monitor on an ISOBUS baler or by a knob located directly on the density valve in front of the baler. No tools are required.

The density harness is a closed and isolated circuit, meaning that there is no continuous oil flow requiring extra power consumption.

The density booster is installed in base on the F441R Baler. The hydraulic device maintains high hydraulic pressure in the density bracket during the complete baling process, even when using a tractor with decreased hydraulic performance.

Thanks to the density booster, the tailgate stays firmly closed from the start of bale formation to the end of the tying process. This increases the bale density and weight. The effect of the density booster is especially visible on small bales of 1.25 m (4.10 ft).

By limiting the trapped air, forage quality is also highly enhanced.

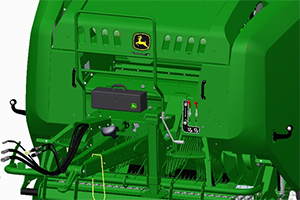

Gull-wing door

Gull-wing door

Gull-wing opening for easy access

The F441R features a single-piece side panel with a gull wing opening to provide full access to the baler side components. No additional shielding needs to be remove to maintain the baler.

The F441R side panels are made of double-skin plastic, providing rigidity and longer durability. The gas cylinders facilitate panel motion and lock it in the upper position safely. The integrated handle facilitates the opening and closing even for small operators. Inner skin (black) has been specially designed to limit crop accumulation.

Gull-wing opening for easy access

The F441R features a single-piece side panel with a gull wing opening to provide full access to the baler side components. No additional shielding needs to be remove to maintain the baler.

The F441R side panels are made of double-skin plastic, providing rigidity and longer durability. The gas cylinders facilitate panel motion and lock it in the upper position safely. The integrated handle facilitates the opening and closing even for small operators. Inner skin (black) has been specially designed to limit crop accumulation.

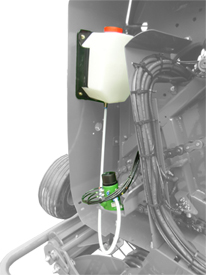

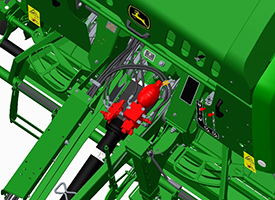

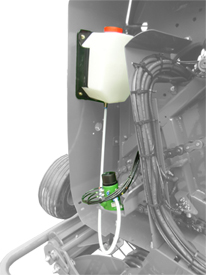

4-L (1-gal.) tank

4-L (1-gal.) tank

Independent settings for all chains

Automatic chain lubrication is offered as standard on the F441R Balers to increase the baler lifespan.

This device features a 4-L (1.05 gal.) high-capacity tank, providing autonomy. The pump delivers continuous flow to all chains as soon as the power take-off (PTO) is engaged. Output can be individually and accurately adjusted. The volumetric pump is guaranteed to lubricate each chain properly, no matter if it is located a few centimeters (inches) from the pump or farther away.

This is designed to work with the John Deere bio multi-luber oil, available through the Parts channel.

Independent settings for all chains

Automatic chain lubrication is offered as standard on the F441R Balers to increase the baler lifespan.

This device features a 4-L (1.05 gal.) high-capacity tank, providing autonomy. The pump delivers continuous flow to all chains as soon as the power take-off (PTO) is engaged. Output can be individually and accurately adjusted. The volumetric pump is guaranteed to lubricate each chain properly, no matter if it is located a few centimeters (inches) from the pump or farther away.

This is designed to work with the John Deere bio multi-luber oil, available through the Parts channel.

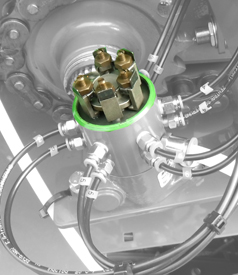

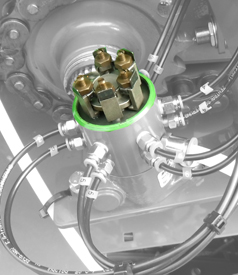

Several greasing zerks in one place

The F441R features a grease bank as base. Most of the greasing points are gathered on banks, delivering grease to the bearings. Downtime linked to daily service is significantly limited, while the operator’s comfort is enhanced.

Several greasing zerks in one place

The F441R features a grease bank as base. Most of the greasing points are gathered on banks, delivering grease to the bearings. Downtime linked to daily service is significantly limited, while the operator’s comfort is enhanced.

Standard grease cartridge inserted into steel tube

Standard grease cartridge inserted into steel tube

Steel tube inserted into the greasing system

The F441R can be delivered as an option with an automatic greasing pump using cartridge and avoiding daily maintenance. The pump is hydraulically piloted and sends an adjustable quantity of grease to intermediate banks during each opening and closing tailgate cycle.

The system is easily filled by inserting a standard grease cartridge (400 g [14.1 oz]) into the steel tube. This system allows a clean and efficient solution, offering two to seven days autonomy.

When empty, a mechanical visual indicator located on the baler front panel warns the operator to change the cartridge.

NOTE: This device is compatible with all monitor types and does not require ISOBUS capability.

Steel tube inserted into the greasing system

The F441R can be delivered as an option with an automatic greasing pump using cartridge and avoiding daily maintenance. The pump is hydraulically piloted and sends an adjustable quantity of grease to intermediate banks during each opening and closing tailgate cycle.

The system is easily filled by inserting a standard grease cartridge (400 g [14.1 oz]) into the steel tube. This system allows a clean and efficient solution, offering two to seven days autonomy.

When empty, a mechanical visual indicator located on the baler front panel warns the operator to change the cartridge.

NOTE: This device is compatible with all monitor types and does not require ISOBUS capability.

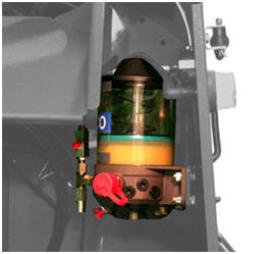

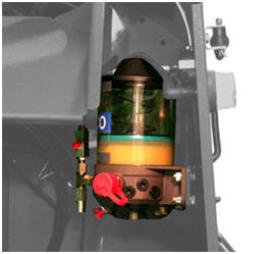

1200-g (42.3-oz) grease capacity

1200-g (42.3-oz) grease capacity

All settings from the display

For the most demanding users, the F441R can be equipped with a high-spec automatic greasing system. As for the cartridge solution, this pump delivers grease to all points requiring some daily maintenance. This option offers several advantages:

All settings from the display

For the most demanding users, the F441R can be equipped with a high-spec automatic greasing system. As for the cartridge solution, this pump delivers grease to all points requiring some daily maintenance. This option offers several advantages:

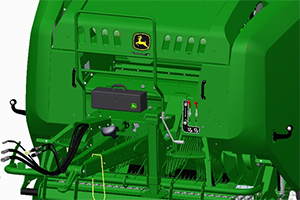

Convenient toolbox location

A toolbox is available as an option for F441R Balers. This device provides storage of tools often used to maintain the baler, such as a grease pump, wrenches, or screwdrivers. The toolbox is conveniently located at the front of the baler.

Convenient toolbox location

A toolbox is available as an option for F441R Balers. This device provides storage of tools often used to maintain the baler, such as a grease pump, wrenches, or screwdrivers. The toolbox is conveniently located at the front of the baler.

Light-emitting diode (LED) lights

Light-emitting diode (LED) lights

Rearview camera

The F441R Baler featuring optional ISOBUS technology can be ordered with the vision pack option. The target of the option is to offer enhanced baling experience by using:

Rearview camera

The F441R Baler featuring optional ISOBUS technology can be ordered with the vision pack option. The target of the option is to offer enhanced baling experience by using:

GreenStar 4240 with F441R main working page

GreenStar 4240 with F441R main working page

Dedicated harness linking baler ISOBUS plug to GreenStar display

The F441R can be delivered with various monitors. At the top of the baler range, the GreenStar 4240 Display can be ordered. This monitor features a 21.5-cm (8.5-in.) diagonal color display. The touchscreen offers an intuitive and user-friendly interface that easily allows operators to adjust and control:

Dedicated harness linking baler ISOBUS plug to GreenStar display

The F441R can be delivered with various monitors. At the top of the baler range, the GreenStar 4240 Display can be ordered. This monitor features a 21.5-cm (8.5-in.) diagonal color display. The touchscreen offers an intuitive and user-friendly interface that easily allows operators to adjust and control:

Comfortable and easy to use

Comfortable and easy to use

Dedicated harness linking baler ISOBUS plug to GreenStar 1800 Display

This monitor features an 18-cm (7-in.) diagonal color display. Access to the functions is easier due to the buttons located on the display side.

The GreenStar 1800 Display is an ISOBUS certified display. The following settings and information are accessible from the monitor:

Dedicated harness linking baler ISOBUS plug to GreenStar 1800 Display

This monitor features an 18-cm (7-in.) diagonal color display. Access to the functions is easier due to the buttons located on the display side.

The GreenStar 1800 Display is an ISOBUS certified display. The following settings and information are accessible from the monitor:

Just plug and bale

Operators with an ISOBUS display already integrated into the tractor do not need to buy an unused component. The F441R Baler with the ISOBUS version can be ordered without the monitor. In this case, the baler is delivered with an ISOBUS plug that must be connected to the tractor’s rear ISOBUS plug.

Just plug and bale

Operators with an ISOBUS display already integrated into the tractor do not need to buy an unused component. The F441R Baler with the ISOBUS version can be ordered without the monitor. In this case, the baler is delivered with an ISOBUS plug that must be connected to the tractor’s rear ISOBUS plug.

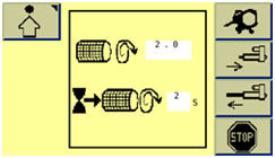

Implement Display 1100

Implement Display 1100

All parameters are highly visible

The F441R Baler has the Implement Display 1100 monitor as an option, offering an 11-cm (4.3-in.) diagonal, high-definition color screen. Icons and information displayed are optimized for an easy reading.

The Implement Display 1100 features:

All parameters are highly visible

The F441R Baler has the Implement Display 1100 monitor as an option, offering an 11-cm (4.3-in.) diagonal, high-definition color screen. Icons and information displayed are optimized for an easy reading.

The Implement Display 1100 features:

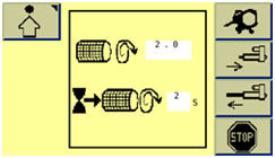

BaleTrak Plus display

The F441R offers the BaleTrak Plus as base (except for the MaxiCut HC 25 Premium version). This robust display offers these functionalities:

BaleTrak Plus display

The F441R offers the BaleTrak Plus as base (except for the MaxiCut HC 25 Premium version). This robust display offers these functionalities:

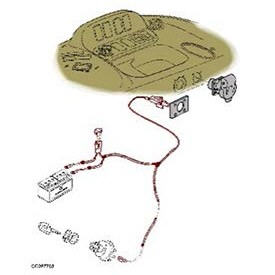

Battery wiring harness

For tractors that do not feature the 12-V, three-pole COBO outlet, a universal battery harness is provided as an attachment. This electrical harness is linked to the tractor’s battery and delivers the 12-V power to the monitor through a standardized plug.

The battery wiring harness is only available as bundle to retrofit multiples tractors.

COBO is a trademark of C.O.B.O. S.P.A. Joint Stock Company Italy.

Battery wiring harness

For tractors that do not feature the 12-V, three-pole COBO outlet, a universal battery harness is provided as an attachment. This electrical harness is linked to the tractor’s battery and delivers the 12-V power to the monitor through a standardized plug.

The battery wiring harness is only available as bundle to retrofit multiples tractors.

COBO is a trademark of C.O.B.O. S.P.A. Joint Stock Company Italy.

F441R tire range

Agronomy, weather conditions, and roads are key points when choosing tires. To match these needs, the F441R offers a wide-range of tires, from narrow 45.7-cm (18-in.) tires, to large 600/50/22.5 tires. The variety offers easy field entering, travel on uneven roads, and less damage to grassy turf areas.

F441R tire range

Agronomy, weather conditions, and roads are key points when choosing tires. To match these needs, the F441R offers a wide-range of tires, from narrow 45.7-cm (18-in.) tires, to large 600/50/22.5 tires. The variety offers easy field entering, travel on uneven roads, and less damage to grassy turf areas.

600/50-22.5 tread

The F441R can bale in very wet conditions. The extra-wide tire size is proposed as an option. With 60-cm (23.6-in.) width and a large 1.17-m (3.84-ft) diameter, the 600/50-22.5 tires limit the soil damage and compaction. These tires are helpful on land where soil bearing is highly limited due to heavy rain. Overall baler width with 600/50-22.5 tires is 2.75 m (9.02 ft).

600/50-22.5 tread

The F441R can bale in very wet conditions. The extra-wide tire size is proposed as an option. With 60-cm (23.6-in.) width and a large 1.17-m (3.84-ft) diameter, the 600/50-22.5 tires limit the soil damage and compaction. These tires are helpful on land where soil bearing is highly limited due to heavy rain. Overall baler width with 600/50-22.5 tires is 2.75 m (9.02 ft).

520/55R22.5 special pattern

In addition to the extra-wide tires, John Deere offers a high-spec tire option for the F441R. The 520/55R22.5 tires feature several advantages:

520/55R22.5 special pattern

In addition to the extra-wide tires, John Deere offers a high-spec tire option for the F441R. The 520/55R22.5 tires feature several advantages:

500/55-20 pattern

500/55-20 tire represents a universal solution:

500/55-20 pattern

500/55-20 tire represents a universal solution:

16/70-20 chevron-pattern profile

The 16/70-20 chevron-pattern tires have been developed for special applications such as wet rice fields or very sloppy conditions. The chevron pattern guarantees a perfect tire rotation even in very muddy or wet conditions and limits lateral machine slippage when working in mountains.

The 16/70-20 chevron-pattern tires feature a large 110-cm (43.3-in.) diameter and keep a very narrow machine (2.37-m [7.8-ft] overall width).

16/70-20 chevron-pattern profile

The 16/70-20 chevron-pattern tires have been developed for special applications such as wet rice fields or very sloppy conditions. The chevron pattern guarantees a perfect tire rotation even in very muddy or wet conditions and limits lateral machine slippage when working in mountains.

The 16/70-20 chevron-pattern tires feature a large 110-cm (43.3-in.) diameter and keep a very narrow machine (2.37-m [7.8-ft] overall width).

15/70-18 tires

15/70-18 tires are offered as a base on the F441R Balers. The tires feature a high-diameter of 1.0 m (3.28 ft) and a width of 39 cm (15.35 in.). Overall baler width with 15/70-18 is 2.34 m (7.68 ft).

15/70-18 tires

15/70-18 tires are offered as a base on the F441R Balers. The tires feature a high-diameter of 1.0 m (3.28 ft) and a width of 39 cm (15.35 in.). Overall baler width with 15/70-18 is 2.34 m (7.68 ft).

High-definition camera

High-definition camera

GreenStar™ 3/Gen 4 display with video preparation

You can more clearly and conveniently keep an eye on the baling process with an updated video camera on F441R, V4X1R, and C4X1R Balers equipped with Vision Pack.

The factory-installed camera offers:

GreenStar™ 3/Gen 4 display with video preparation

You can more clearly and conveniently keep an eye on the baling process with an updated video camera on F441R, V4X1R, and C4X1R Balers equipped with Vision Pack.

The factory-installed camera offers:

Dedicated screen with single camera view

Dedicated screen with single camera view

Dedicated screen with four-camera view

If you are not using a John Deere tractor with the 4240 Universal Display or GreenStar 3/Gen 4 integrated CommandCenter™ system, a dedicated screen is available.

Dedicated screen with four-camera view

If you are not using a John Deere tractor with the 4240 Universal Display or GreenStar 3/Gen 4 integrated CommandCenter™ system, a dedicated screen is available.

High-capacity feeding system boosts productivity

Pickup design improves capacity and durability

Large-diameter stripper and five teeth bars provide high picking capacity

Large-diameter stripper and five teeth bars provide high picking capacity Forged cam-track links improve reliability

Forged cam-track links improve reliability- No rust

- Constant gliding capacity

- High resistance to aggressive additives such as propionic acids

- Features a short space between the tines and rotor, limiting dead zone.

- Avoids pinching area, so no crops are plugged into the pickup drums.

High-capacity (HC) rotor for higher productivity and durability

MaxiCut™ HC 25 Premium has a single axis for rotor and converging augers

MaxiCut™ HC 25 Premium has a single axis for rotor and converging augers HC rotor limits plugs

HC rotor limits plugs| MaxiCut HC 13 Premium | MaxiCut HC 25 Premium | |

|

Number of knives |

0, 13 |

0, 12, 13, 25 |

|

Space between knives (full crop length) |

80 mm (3.15 in.) |

40 mm (1.57 in.) or 80 mm (3.15 in.) |

|

Best use (crop type) |

Silage, hay, and straw |

Silage, hay, and straw |

High cutting quality provides better forage

Double-heat treatment for concise cut and long life

Double-heat treatment for concise cut and long life Individual knife security for quality forage

Individual knife security for quality forage- Bulk heat treatment to reduce risk of knife breakage.

- Surface heat treatment of the cutting area to provide better cutting quality and knife durability.

Select number of knives from the cab to increase uptime

Knife activation from the BaleTrak™ monitor

Knife activation from the BaleTrak™ monitor Knife sets from the cab with MaxiCut HC 25 Premium

Knife sets from the cab with MaxiCut HC 25 PremiumDrop floor can remove the worst plugs

Drop floor covers rotor full width

Drop floor covers rotor full width Parallel kinematics avoids narrowing

Parallel kinematics avoids narrowing- Full-width design – by covering the full pickup width, the device is able to remove plugs, even located under converging augers.

- Parallel kinematic – no rear or front hinge means no narrowing. The F441R drop floor offers a constant 40-mm (1.6-in.) free space through the feeding channel when activated. This is enough to decompress the crops and avoid crop loss.

Heavy-duty bale chamber provides density, durability, and multi-crop capability

Rolls manufacturing provides long lifespan

12 ribs roll

12 ribs roll Bearings protection feature chicane and lips plastic seal

Bearings protection feature chicane and lips plastic seal Fully greaseable bearings can be replaced easily

Fully greaseable bearings can be replaced easilySpecific rolls handle the stress

Blue and red rolls are heavy duty

Blue and red rolls are heavy duty- Rolls numbered 14 and 17 (blue) transmit the load of the main drive to the secondary chains (front bale chamber part and tailgate) and the pair of bottom roll numbered 10 and 11 (red) carry most of the bale weight. Due to this specific stress, these rolls feature a higher thickness of 4 mm (0.16 in.) instead of 3.2 mm (0.13 in.) and specific shafts in order to achieve requested durability.

Damped gate cylinders

Damped gate cylinders

Damped gate cylindersAdjust bale size and density independently and maximize bale weight

Green column indicates bale diameter target – black column indicates bale diameter status

Green column indicates bale diameter target – black column indicates bale diameter status Bales density can be adjusted from ISOBUS monitors through proportional density valve

Bales density can be adjusted from ISOBUS monitors through proportional density valveFacilitated maintenance increases uptime

Single-piece side panels offer easy-access to components

Gull-wing door

Gull-wing door Gull-wing opening for easy access

Gull-wing opening for easy accessAutomatic chain lubrication increases component durability

4-L (1-gal.) tank

4-L (1-gal.) tank Independent settings for all chains

Independent settings for all chainsGreasing bank gathers most of the zerks

Several greasing zerks in one place

Several greasing zerks in one placeAutomatic greasing system with cartridge provides an affordable and comfortable solution

Standard grease cartridge inserted into steel tube

Standard grease cartridge inserted into steel tube Steel tube inserted into the greasing system

Steel tube inserted into the greasing system| Option code | Attachment | Description |

| 1580 | Manual greasing – centralized greasing banks | |

| 1581 | Automatic greasing – cartridge system | |

| 1582 | Automatic greasing – tank system | |

| AFH210314 | Quick-fill grease gun for automatic greasing pump – cartridge system | |

| 8016 | Toolbox | |

| 8089 | BCC10506 | Vision pack NOTE: Delivered without camera when ordered as an attachment. |

ISOBUS automatic greasing system with tank offers advanced settings and high autonomy

1200-g (42.3-oz) grease capacity

1200-g (42.3-oz) grease capacity All settings from the display

All settings from the display- High autonomy with 1200 g (42.3 oz) of grease (three standard cartridges). Re-filling is only required once a week to once a month.

- Refilling is possible through the standard zerk.

- Refilling is possible with a dedicated high-throughput plug, minimizing downtime (fast refill pump is available as an attachment).

- Greasing and non-greasing time is adjustable from the monitor.

- Greasing activation can be done from the monitor.

- Greasing process status is displayed on the monitor.

Toolbox facilitates maintenance

Convenient toolbox location

Convenient toolbox locationVision pack enhances operator’s baling experience

Light-emitting diode (LED) lights

Light-emitting diode (LED) lights Rearview camera

Rearview camera- Lights in the net system and side panels piloted from the monitor in order to allow maintenance at night and in dark conditions.

- A rearview camera in order to control the bale unloading process directly from the cab. The camera is not delivered with a dedicated screen but is designed to be plugged into John Deere tractors that feature video preparation/capacity. A dedicated thin-film transistor (TFT) screen can be ordered independently through the traditional Parts channel.

Fit needs with wide monitor choice

GreenStar™ 4240 Display enhances operator comfort

NOTE: Limited availability for model year 2019. GreenStar 4240 with F441R main working page

GreenStar 4240 with F441R main working page Dedicated harness linking baler ISOBUS plug to GreenStar display

Dedicated harness linking baler ISOBUS plug to GreenStar display- Bale diameter setting and status

- Bale density setting and status

- Gate and bale position

- Twine/net settings and status

- Drop floor management and status

- Knife management and status

- Automatic tailgate management

- Tractor Baler Automation management

- Rearview camera management (dedicated harness to be added)

- Greasing parameters and status when automatic greasing option is chosen

- Bale counter (99 resettable options plus one total bale count option)

- Electrical harness and sensor status

- GreenStar 4240 Display

- Baler to rear tractor ISOBUS plug

- Baler ISOBUS plug to display harness (requires 12-V COBO™ plug)

- Tractor cab corner to monitor harness

GreenStar 1800 Display simplifies baler use

NOTE: Limited availability for model year 2019. Comfortable and easy to use

Comfortable and easy to use Dedicated harness linking baler ISOBUS plug to GreenStar 1800 Display

Dedicated harness linking baler ISOBUS plug to GreenStar 1800 Display- Bale diameter setting and status

- Bale density setting and status

- Gate and bale position

- Twine/net settings and status

- Drop floor management and status

- Knives management and status

- Automatic tailgate management

- Tractor Baler Automation management

- Greasing parameters and status when automatic greasing option is chosen

- Bale counter (99 resettable options plus one total bale count option)

- Electrical harness and sensor status

- GreenStar 1800 Display

- Baler to rear tractor ISOBUS plug

- Baler ISOBUS plug to display harness (requires 12-V COBO plug)

- Tractor cab corner to monitor harness

No monitor offers a solution for modern ISOBUS tractors

Just plug and bale

Just plug and baleMonitor support for John Deere SG2 cab and other brands

Monitors are not delivered with support. A support allowing the monitor to fasten to the cab is available for following tractors:- John Deere with SG2 cab (produced before 1992)

- All others brands with specific modifications

Implement Display 1100 offers an appealing and affordable solution

Implement Display 1100

Implement Display 1100 All parameters are highly visible

All parameters are highly visible- Bale diameter setting and status

- Bale density setting and status

- Gate and bale position

- Net settings and status

- Drop floor management and status

- Knives management and status

- Automatic tailgate management (when option chosen)

- Greasing parameters and status when automatic greasing option is chosen (99 resettable bale count options plus one total bale count)

- Full-text error information

- Electrical harness and sensor status

BaleTrak™ Plus monitor offers a user-friendly solution

BaleTrak Plus display

BaleTrak Plus display- Bale diameter setting and status

- Gate position status

- Net settings and status

- Drop floor management

- Knife management

- Bale counter (five resettable bale count settings plus one total bale count)

Monitor support for John Deere 5XXX, 6XXX, and 7XXX Tractors

Monitors, no matter the type, are not delivered with support. A support allowing the monitor to fasten to the cab corner or side is available for the 5XXX, 6XXX, and 7XXX John Deere Tractor Series. This monitor bracket can also be delivered as a field attachment.Battery wiring harness delivers 12-V power to the monitor

Battery wiring harness

Battery wiring harnessLimit soil compaction with wide tires

Large tire range to fit operator needs

F441R tire range

F441R tire range 600/50-22.5 fits wet conditions

600/50-22.5 tread

600/50-22.5 treadLow pressure 520/55R22.5 limit soil impact

520/55R22.5 special pattern

520/55R22.5 special pattern- Large 1.14-m (3.7-ft) diameter tires offer reduced traction and fuel consumption

- 52-cm (20.47-in.) width tires limit soil damage

- Radial tread design, combined with low-pressure inflation, provides low soil compaction.

- Radial tread design increases efficiency and durability for road transportation.

- A special tire pattern increases tire grip while baling on slopes.

500/55-20 provides a universal solution

500/55-20 pattern

500/55-20 pattern- 51.5-cm (20.28-in.) width limits soil damages

- 106-cm (41.73-in.) diameter offers easy traction

- High side wall of the tire offers good flotation capabilities

16/70-20 chevron-pattern tire answers specific needs

16/70-20 chevron-pattern profile

16/70-20 chevron-pattern profile15/70-18 tires

15/70-18 tires

15/70-18 tiresImprove visibility to baler options with updated video camera and screen options

High-definition camera

High-definition camera GreenStar™ 3/Gen 4 display with video preparation

GreenStar™ 3/Gen 4 display with video preparation- Higher definition with 77 percent more pixels

- Wider view of 120 degrees instead of 90 degrees

- Night vision thanks to infrared light-emitting diodes (LEDs)

- Better visibility in very bright or contrasted environments

- Integrated heating system to prevent dew from forming on the lens and obscuring the screen

- Long 10-m (32.8-ft) harness for ease of use

Dedicated screen with single camera view

Dedicated screen with single camera view Dedicated screen with four-camera view

Dedicated screen with four-camera view- Clear picture with 17.8-cm (7-in.) 16/9 high-definition color screen

- Compatible with up to four cameras with split-screen or toggle-screen function

- Adjustable brightness and contrast provide optimum viewing

- Anti-reflection screen decreases glare

Dealer use only:

For producers looking to install multiple cameras (for pickup/net system view, etc.), the updated Vision Pack camera is also available through the Parts channel. The camera delivered with Vision Pack is compatible with the tractor video preparation plug for GreenStar 3/Gen 4 integrated CommandCenter. There are no changes to compatibility with the 4240 Universal Display. PFP17673 bulkhead harness (available through the Parts channel) is still required to display video if the 4240 Universal Display is plugged into the tractor cornerpost. The dedicated screen is available as an option or as field bundle. Before placing an order, please reference Configurator or the Build and Price tool for any recent revisions to the below information.| Code | Attachment | Description |

| 8089 | Vision Pack NOTE: For F441R, V4X1R and C4X1R Balers produced from 20 January 2020. | |

| 9781 | BCC10645 | 17.8-cm (7-in.) high-definition screen for Vision Pack camera |

Offers and Discounts

Related Products

Product Information & Support

You May Also Be Interested In

Product features are based on published information at the time of publication. Product features are subject to change without notice. Contact your local John Deere dealer for more information.