- GOLF COURSE EQUIPMENT

- SPORTS TURF

- INDUSTRIAL DIESEL ENGINES

- MARINE ENGINES

- GENERATOR DRIVE ENGINES

- DRIVETRAIN EQUIPMENT

- TRACTORS & MOWERS

- CONSTRUCTION

- UTILITY VEHICLES & ACCESSORIES

- ATTACHMENTS & ACCESSORIES

Features

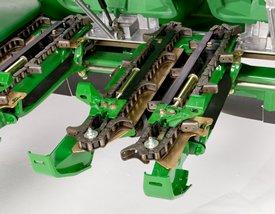

Gathering chains designed for increased life

600C Row-Unit

600C Row-Unit

The massive gathering chains are based on a CA620 chain design with deep conveying lugs for high levels of productivity.

Customer Value:

- Large, deep conveying lugs provide high levels of productivity for faster harvesting.

- Robust design and construction ensure maximum uptime and minimum maintenance.

Theory of Operation:

The massive gathering chains are based on a CA620 chain design. After the initial stretch of this chain, the operator can expect increased chain life and adjustment once a season.

Attached to the gathering chain are conveying lugs. The gathering chain is exposed at the front of the row-unit to enable better gather of down corn, while the attachment link profile reduces trash intake and shelling loss.

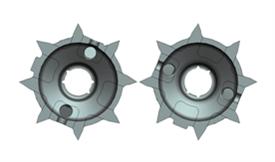

Idler sprocket on 600C Corn Head

Idler sprocket on 600C Corn Head

The idler sprockets were designed to distribute chain load and increase chain life. The idler bearing contains a triple-lip seal plus an additional sealed outer steel shroud for greatly increased bearing protection.

Chain guide on 600C

Chain guide on 600C

The chain guides have been designed with a raised roller surface to ensure gathering chains roll on the profile of the guide. Running on the rollers of the chain increases overall system efficiency by reducing friction, which results in increased gathering chain life.

600C Series dual-auger strippers significantly reduce amount of auger wrapping

Dual-auger strippers

Dual-auger strippers

The 600 Series Corn Head dual-auger strippers significantly reduce the amount of auger wrapping in heavy grass, vines, or wet/damp down corn, as well as keeping ears down in the auger floor rather than riding over the top of auger.

Both auger strippers are strategically located, so the top stripper remains at the needed position relative to the auger flighting and does not require adjustment.

Once the auger has been set to the crop condition, the lower stripper can be adjusted 6 mm to 13 mm (1/4 in. to 1/2 in.) to the auger flighting.

Cross auger provides unmatched crop-handling capacity

Large, 45.7-cm (18-in.) auger

Large, 45.7-cm (18-in.) auger

The 600C Corn Heads feature a large, 45.7-cm (18-in.) tip diameter cross auger provides unmatched crop-handling capacity.

Customer Value:

- The deep auger flight design provides for even crop material flow, allowing faster harvesting speeds.

Auger to row-unit speed is optimized to feeding of crop and minimizing crop loss due to ear tossing.

Theory of Operation:

Reverse center auger flighting

Reverse center auger flighting

The cross auger flighting is reversed in the center, tilting back 20 degrees at the beginning and then an additional 20 degrees the last 5.08 cm (2 in.) toward the tip. The reverse flighting offers improved feeding in dry trash and reduced ear tossing and will prevent the wrapping of crop. The 66-cm (26-in.) pitch on the cross auger provides quick delivery of crop to the feederhouse, allowing for faster and much smoother crop feeding.

The 600 Series cross auger runs at a speed of 135 rpm with the combine backshaft speed set at 700 rpm. The slower auger speed reduces ear tossing in front of the feederhouse and keeps material moving from the back of the row-unit into the auger. Keeping the material flowing helps dry trash and down corn feeding.

Adjustment of the cross auger can be done by loosening the bolts at each end of the head and moving the auger up or down.

Opposed stalk roll options for premium stalk processing

600C Row Unit

600C Row Unit

The opposed knife stalk rolls are the best equipment when the typical harvesting condition is dry corn and using the StalkMaster™ stalk chopping option.

Customer Value:

- Majority of stalk material will be sized at 12 inches or longer to provide soil protection from wind and water.

- Designed to harvest with low power consumption for high performance and low fuel consumption.

Manufactured of highly durable material for longer wear life.

Theory of Operation:

Opposed knife stalk roll

Opposed knife stalk roll

Rolls are designed with eight opposed, full-length blades that result in better stalk control, improved stalk processing, and reduced material-other-than-grain (MOG) intake. This eight-blade design improves function and reduces localized blade wear in the front of the rolls. Rolls are constructed of austempered ductile iron material with a dual coating in the front 7.6 cm (3 in.) of high-wear zone for longer life.

The stalk rolls turn at 1050 rpm when back shaft speed is at 700 rpm. The tip speed compared to the gathering chain speed is optimized to reduce MOG intake and increase overall capacity while minimizing losses.

The single-piece cast knife roll design provides excellent serviceability when replacement is required.

Straight-fluted stalk rolls

Straight-fluted stalk roll

Straight-fluted stalk roll

The straight-fluted stalk rolls are the best equipment when the maximum stalk residue length is desired.

Customer Value:

- Majority of stalk material will be sized at to 30.5 cm (12 in.) or longer to provide maximum soil protection from wind and water.

- Designed to harvest with very low power consumption for high performance and low fuel consumption.

- Manufactured of highly durable material for longer wear life.

Theory of Operation:

Straight-fluted stalk rolls are designed with eight opposed, full-length flutes that result in good stalk control and reduced material other than grain (MOG) intake. The full-length flutes provide total crop contact for minimal crop loss and more even wear from the front to back. Rolls are constructed of austempered ductile iron material with a dual coating in the front 7.6 cm (3 in.) of high-wear zone for longer life.

The stalk rolls turn at 735 rpm when back shaft speed is at 490 rpm. The tip speed compared to the gathering chain speed is optimized to reduce MOG intake and increase overall capacity while minimizing losses.

The single-piece cast knife roll design provides excellent serviceability when replacement is required.

Lower auger bed floor offers distinct advantages

Auger bed floor

Auger bed floor

The entrance into the auger bed floor of the 600 Series Corn Head has been lowered in comparison to previous John Deere corn heads. This enables gravity to do its job and let crop follow the slope designed into the auger bed and move it quickly away from the row-unit.

Customer Value:

- The design of the auger bed floor minimizes the loss of free grain.

- The geometry reduces the chance of damage to the ear due to backfeeding or hesitation at the rear of the row-unit.

- Auger strippers improve crop flow in challenging crop conditions maximizing performance and harvesting speed.

Theory of Operation:

The cross auger flighting is reversed in the center, tilting back 20 degrees at the beginning and then an additional 20 degrees the last 5.08 cm (2 in.) toward the tip. The reverse flighting offers improved feeding in dry trash and reduced ear tossing and will prevent the wrapping of crop. The 66-cm (26-in.) pitch on the cross auger provides quick delivery of crop to the feederhouse, allowing for faster and much smoother crop feeding.

The 600 Series cross auger runs at a speed of 135 rpm with the combine backshaft speed set at 700 rpm. The slower auger speed reduces ear tossing in front of the feederhouse and keeps material moving from the back of the row-unit into the auger. Keeping the material flowing helps dry trash and down corn feeding.

Adjustment of the cross auger can be done by loosening the bolts at each end of the head and moving the auger up or down.

Dual-auger strippers

Dual-auger strippers

The 600 Series Corn Head dual-auger strippers significantly reduce the amount of auger wrapping in heavy grass, vines, or wet/damp down corn, as well as keeping ears down in the auger floor rather than riding over the top of auger.

Both auger strippers are strategically located, so the top stripper remains at the needed position relative to the auger flighting and does not require adjustment.

Once the auger has been set to the crop condition, the lower stripper can be adjusted 6 mm to 13 mm (1/4 in. to 1/2 in.) to the auger flighting.

Perma-Glide™ points and deck covers enable operator to quickly and easily access row unit

Perma-Glide points and deck covers

Perma-Glide points and deck covers

600C Series Corn Heads row unit points and covers are constructed with a tough, durable, solid polyethylene material known as Perma-Glide.

Customer Value:

- Surfaces will not rust and resist dents providing maintenance free operation.

- Reinforcement ribs for greater strength and reliability to ensure maximum up time.

- Smooth surface and very low coefficient of friction provides easier feeding of crop and material into the header, especially in down crop conditions maximizing performance.

Theory of Operation:

The Perma-Glide points and deck covers can be quickly and easily raised for access to each row-unit. No tools are required.

Row-unit point

Row-unit point

Outside gathering chains and sprockets

Outside gathering chains and sprockets

Simply raise the row-unit point, and the spring-loaded pull pin will automatically latch. To raise the deck cover, just pull the slam latch deck cover lever and lift the entire point and cover straight up and out of the way. All inner points and deck covers incorporate a gas strut lift-assist cylinder that reduces the lifting force and maintains the point and deck covers in the upright position eliminating the holding rod.

In order to access the outside gathering chains and sprockets, simply raise the row-unit point (like the inside row-unit points), pull the spring-loaded pin located at the back of the unit, and tip the cover outward.

Outside gathering chains and sprockets

Outside gathering chains and sprockets

Perma-Glide points are easy to adjust and level. Simply pull out on the spring-loaded pin and adjust the height to one of four predetermined positions. No tools are required and no time-consuming height adjustment bolt or chain is used.

The gathering sheet extensions are integrated into the outer gathering shields. In order to extend the gathering sheet, simply raise the extension. The spring-loaded button will snap into place, securing the gathering sheet in the upright position for specific conditions where extended gathering shields are needed.

To lower the extension, push in on the spring-loaded button and lower the gathering sheet into the storage position.

Ear-saver shields

Ear-saver shields

Ear-saver shields are integrated into the row-unit deck shields. The ear gates, as they are referred to, prevent ears of corn from falling out from the front of each row-unit.

AutoTrac™ RowSense™ solution enables hands-free corn harvest

Feelers signal combine to keep it on the row

Feelers signal combine to keep it on the row

AutoTrac RowSense is a solution for corn growers that increases machine efficiency and reduces operator fatigue. AutoTrac RowSense offers operators the same high levels of convenience and productivity experienced in other crops or with AutoTrac-equipped tractors and self-propelled sprayers.

Customer Value:

- Maintains harvesting efficiency in down crop and low-visibility (dusty) conditions.

- Increases the acre-per-hour performance potential and reduces grain loss.

- Enhances operator comfort and reduces operator stress.

Theory of Operation:

StarFire™ position receiver picks up signal

StarFire™ position receiver picks up signal

Offers and Discounts

Related Products

Product features are based on published information at the time of publication. Product features are subject to change without notice. Contact your local John Deere dealer for more information.